A hard mask film layer structure and manufacturing method of a silicon germanium triode base region

A manufacturing method and masking film technology, which are applied in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of poor photoresist morphology, rough surface of germanium-silicon thin film layer, unfavorable miniaturization of key dimensions, etc. Achieve the effect of improved control ability, small size, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

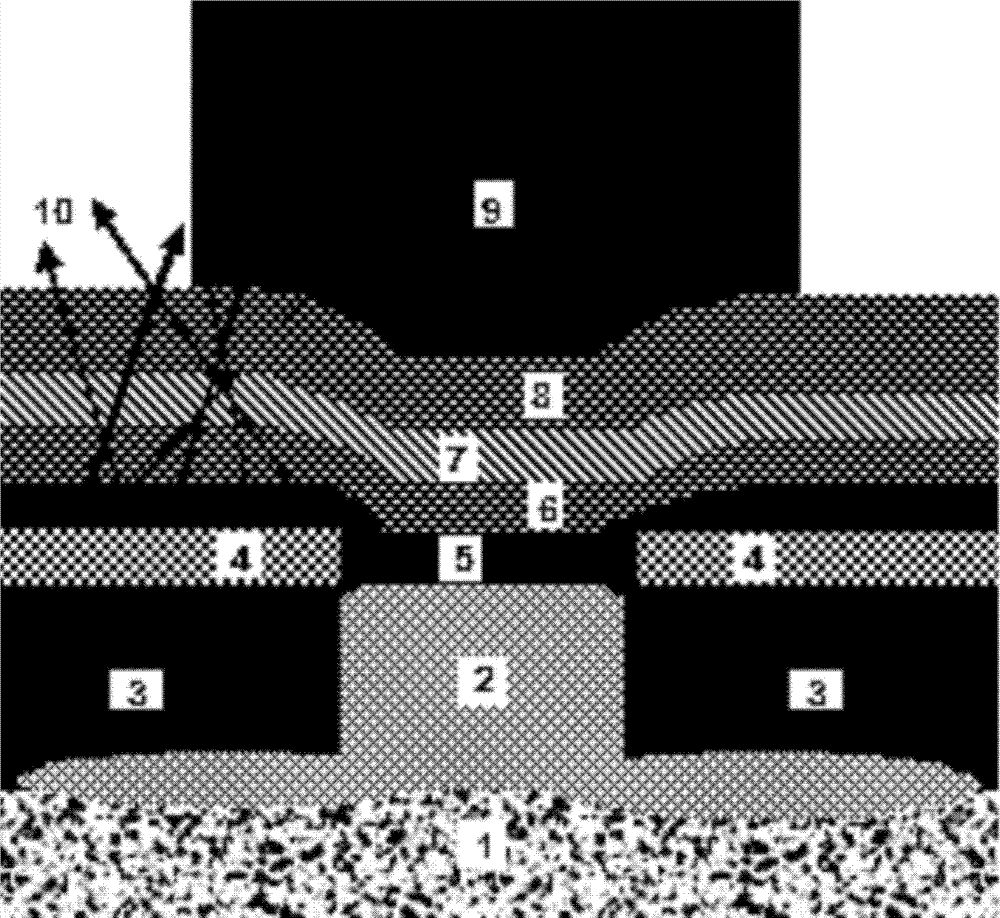

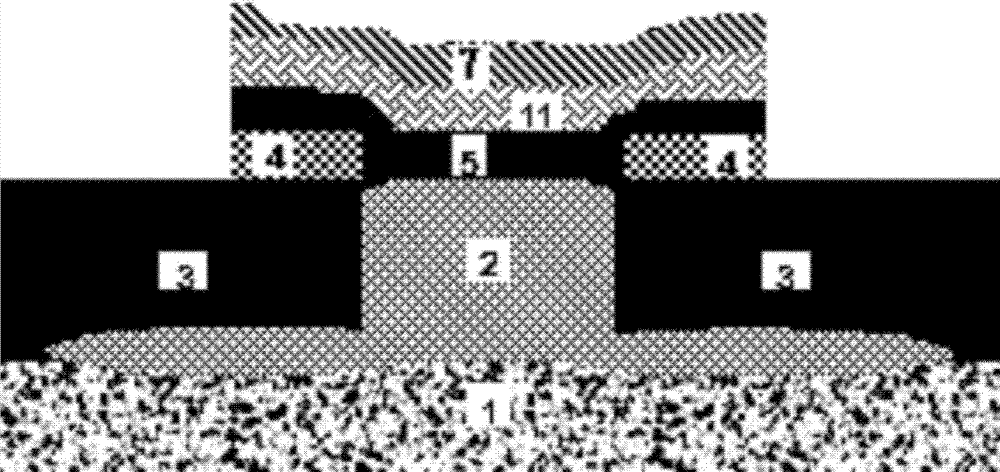

[0048] Such as figure 2 As shown, in the first embodiment, the hard mask film layer structure in the base region of the silicon germanium triode includes:

[0049] A silicon wafer 1 has a collector region 2 and a field isolation region 3 above it, and a polysilicon layer 4 and a silicon-germanium thin film layer 5 are grown on the collector region 2 and the field isolation region 3, wherein a part of the silicon-germanium thin film layer 5 is grown on An inorganic anti-reflection material layer 11 is grown above the polysilicon layer 4 and above the germanium-silicon film layer 5, and a second hard mask layer 7 is grown above the inorganic anti-reflection material layer 11, and the inorganic anti-reflection material layer 11 is used as a hard mask layer use.

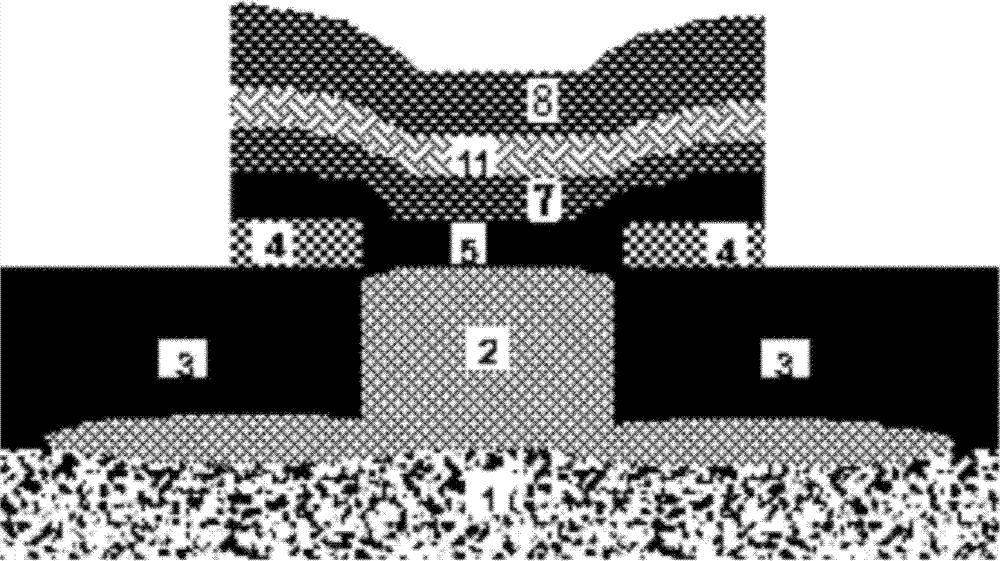

[0050] Such as image 3 As shown, in the second embodiment, the hard mask film layer structure in the base region of the silicon germanium triode includes:

[0051] A silicon chip 1 has a collector region 2 and a fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com