Recycling and Utilization Method of Positive Electrode Slurry Residue

A cathode slurry and slurry technology, which is applied in the field of cathode slurry residual recycling, can solve the problems of slurry waste, increase of excrement volume, easy impact on the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

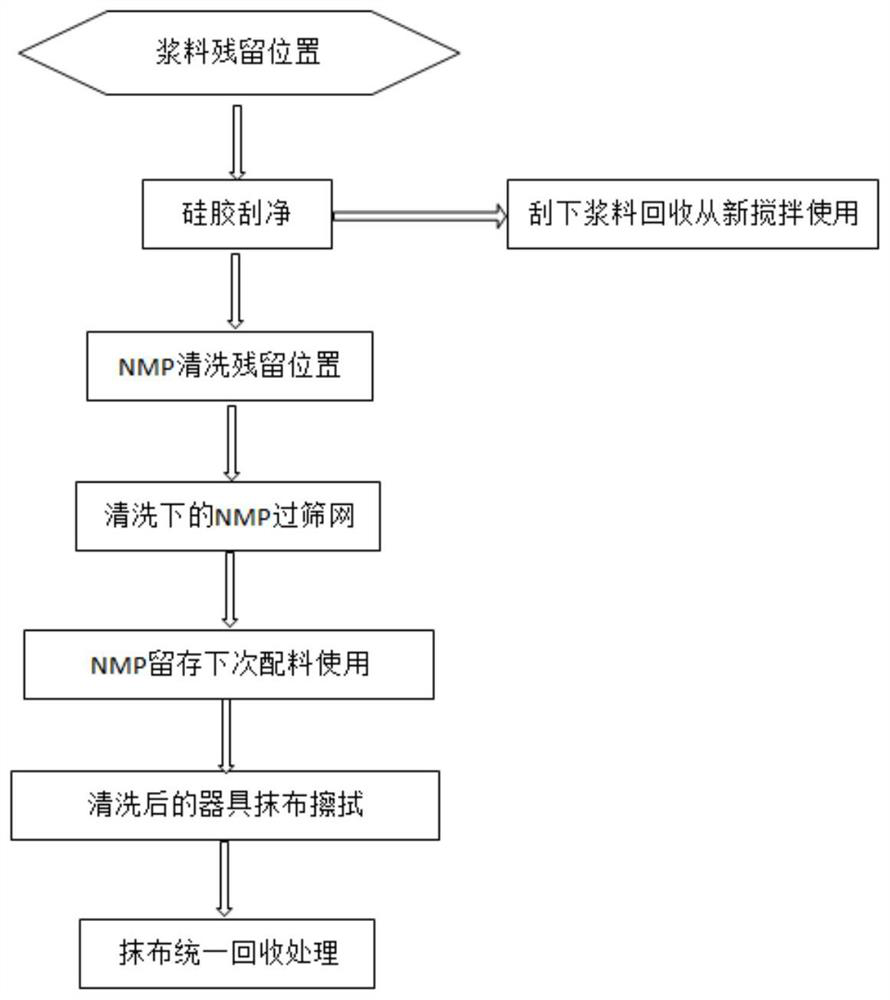

[0044] The process of lithium battery production includes slurry preparation and slurry use, and then there will be a certain amount of residue; positive electrode slurry residue: mixing tank, screen, slurry basin, slurry bucket, chute, baffle plate, Beaker, viscosity needle, steel roller, rag; first briefly describe the recycling method of the slurry residue on the mixing tank: after the mixing tank is discharged, scrape off the residual material on the wall of the tank and the stirring paddle with a silica gel plate, and then stir The barrel is injected into the solvent N-methylpyrrolidone (NMP) used for the positive electrode ingredients, hereinafter referred to as NMP, and the amount of NMP injected is about 80% of the volume of the mixing barrel; the mixing barrel is closed, and vacuum high-speed stirring is carried out for 1H, and the mixture in the stirring barrel is a large amount of The NMP passed through the 200-mesh sieve, and the filtered solvent NMP is used as the ...

Embodiment 2

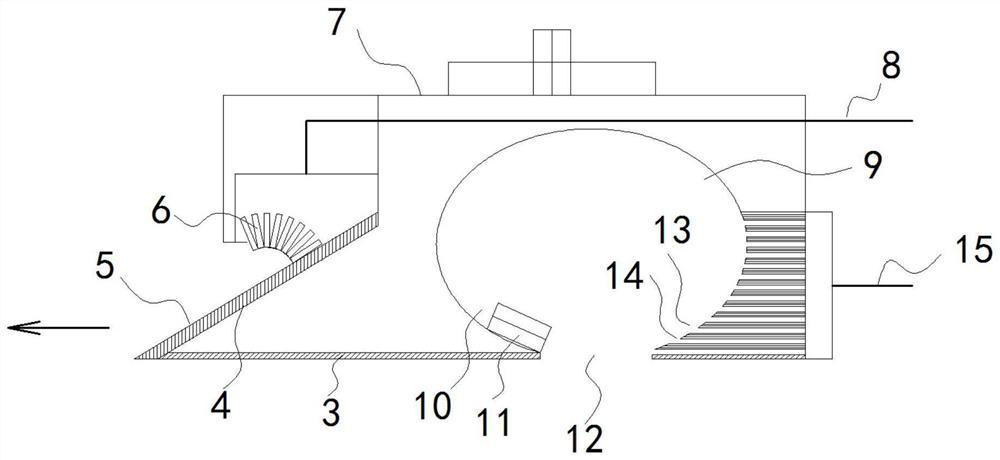

[0046] Using the scraping device to replace the silica gel plate operation, the remaining positions of the treatment include: the inner wall of the slurry pan, the inner wall of the slurry tank, the inner wall of the retaining tank, and the outer wall of the pressure roller. The cleaning method of the mixing tank is the same as in Example 1.

[0047] Turn on the suction pump, vacuum pump and high-pressure pump in the scraper, control the scraper to stick to the above residual position and move through the operating lever, the scraper scoops up the positive electrode slurry above the residual position, and then is sucked by the suction head In the slurry collection bucket (here corresponds to the scraped material), the slurry in the slurry collection bucket can be used as the next batch of positive electrode slurry; at the same time, the high-pressure nozzle sprays the spray solution (NMP) to Spray the surface of the residual position after the slurry, and the spray liquid pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com