Spindle executing device for electric discharge machining of non-rounded regular hexagonal hole and machining method

A technology of regular hexagon and actuator, applied in electric machining equipment, accessories, metal processing equipment, etc., can solve the problems of rounded corners, difficult to meet the expected machining requirements, difficult chip removal, etc., and achieve easy chip removal and lifting. Wear resistance and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

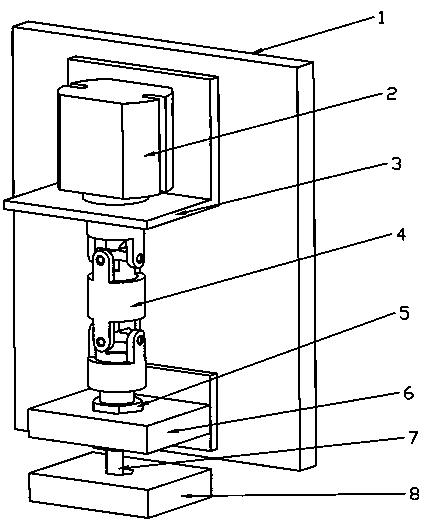

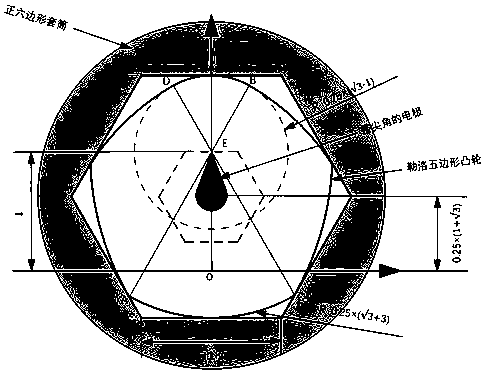

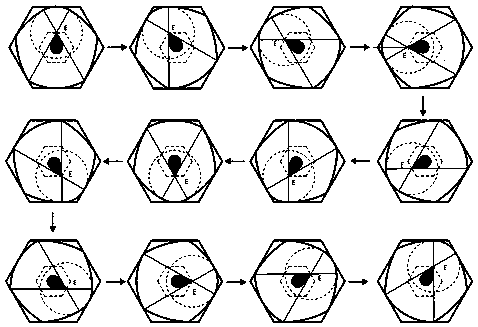

[0022] Specific implementation mode one: see figure 1 According to this embodiment, a spindle actuator for electric discharge machining of a regular hexagonal hole without rounded corners, the device includes a support plate 1, a DC motor 2, a motor bracket 3, a universal coupling 4, and a five-sided Leroux Shaped cam 5, regular hexagonal sleeve 6, sharp angle electrode fixture 7;

[0023] Among them, the motor bracket 3 and the regular hexagonal sleeve 6 are coaxially fixed on the support plate 1, and the motor output shaft, the universal coupling 4, the Lelo pentagonal cam 5, and the sharp-angled electrode 7 are sequentially connected and installed coaxially. The Lolo pentagonal cam 5 is completely fitted and installed in the regular hexagonal sleeve. After the motor is energized, the main shaft is driven to rotate. Revolutionary movement around the mandrel of the regular hexagonal sleeve;

[0024] The pointed electrode 7 is a graphite electrode; the Lelo pentagonal cam 5...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and the spindle actuator for electric discharge machining of regular hexagonal holes without rounded corners described in Embodiment 1 is that the Leroux pentagonal cam 5 and the sharp-angled electrode 7 adopt Threaded connection, which makes the connection more compact, but needs to process the threaded electrode.

specific Embodiment approach 3

[0029] Specific Embodiment 3: The difference between this embodiment and the spindle actuator for electric discharge machining of a regular hexagonal hole without rounded corners described in the first or second specific embodiment is that the Leroux pentagonal cam 5 and the regular hexagonal The edge-shaped sleeve 6 can adopt heat treatment methods such as carburizing and quenching or nitriding treatment to improve the surface hardness and wear resistance of the cam mechanism. Compared with the specific embodiment 1, it has the advantage of not requiring secondary processing, but the heat treatment process is relatively cumbersome.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com