Method for strengthening noble metal enriching by copper-based solid waste cooperative matte smelting

A precious metal, copper-based technology, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve the problems of high processing cost, large output of three wastes, poor material adaptability, etc., achieving simple process flow and strong adaptability of raw materials. , The effect of high temperature volatilization is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

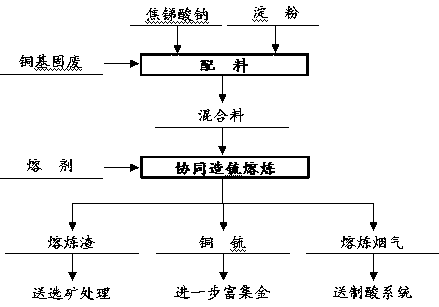

Image

Examples

Embodiment 1

[0021] The copper-based solid waste described in the present invention has two kinds, the first kind of electroplating sludge, the mass percentage content of its main component is: Cu12.35% and Au12g / t; The second kind is wet-process copper sludge, its main The mass percentage of the components is: Cu32.0% and Au40g / t; the mass percentage of the main component of sodium pyroantimonate is: NaSb(OH) 6 98.2%, the mass percentage of FeO in iron ore is 58.44%, the mass percentage of CaO in limestone is 48.5%, and the FeS in pyrite 2 The mass percentage is 85.3%.

[0022] First, mix sodium pyroantimonate, starch and water according to the weight ratio of 100:5.0:6.0 and then granulate, keeping the particle size of sodium pyroantimonate at 1.5mm; secondly, mix sodium pyroantimonate pellets, copper-based solid waste and yellow The iron ore is mixed with ingredients so that the contents of antimony, copper and sulfur in the mixture are kept at 0.80%, 26.5% and 18.0% respectively. Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com