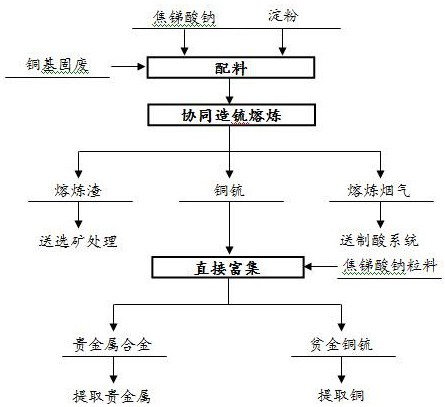

A method for copper-based solid waste collaborative smelting enrichment and extraction of precious metals

A precious metal, copper-based technology, applied in the field of copper-based solid waste co-smelting process for enrichment and extraction of precious metals, can solve the problems of high processing cost, large output of three wastes, poor material adaptability, etc. less volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The copper-based solid waste described in the present invention has two kinds, the first kind of electroplating sludge, the mass percentage content of its main component is: Cu12.35% and Au12g / t; The second kind is wet-process copper sludge, its main The mass percentage of the components is: Cu32.0% and Au40g / t; the mass percentage of the main component of sodium pyroantimonate is: NaSb(OH) 6 98.2%, the mass percentage of FeO in iron ore is 58.44%, the mass percentage of CaO in limestone is 48.5%, and the FeS in pyrite 2 The mass percentage is 85.3%.

[0024] First, sodium pyroantimonate, starch and water are mixed according to the weight ratio of 100:5.0:6.0 and then granulated to keep the particle size of sodium pyroantimonate at 1.5mm. Then sodium pyroantimonate pellets, copper-based solid waste and yellow The iron ore is mixed with ingredients so that the contents of antimony, copper and sulfur in the mixture are kept at 0.80%, 26.5% and 18.0% respectively. Second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com