Method for recovering free starch in papermaking white water

A technology of papermaking white water and cationic starch, which is applied in the field of pulping and papermaking, can solve the problems of paper defects, broken ends, affecting operation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0321] Example 1 Effect of cationic starch binder cetylpyridine hydrochloride (number C7) on starch dissolution and fiber surface adsorption after reacting with starch

[0322] Experimental steps: (1) take cornstarch sample and prepare 7% "standard starch solution"; (2) take an appropriate amount of standard starch solution and add deionized water to dilute to the required concentration of starch solution; (3) take the prepared concentration Put 500mL of starch solution in a beaker, and put it into a 45°C constant temperature water bath, and equilibrate to the specified temperature; (4) Add C7 according to the required concentration, and react for 60 minutes to obtain a modified starch solution; (5) Sampling and centrifuging ( 4000x g) for 5 minutes, take the supernatant to test the starch concentration; (6) add bleached chemical pulp (BKP) to the remaining modified starch solution according to a solid concentration of 1%, and keep stirring for 10 minutes; (7) after the reactio...

Embodiment 2

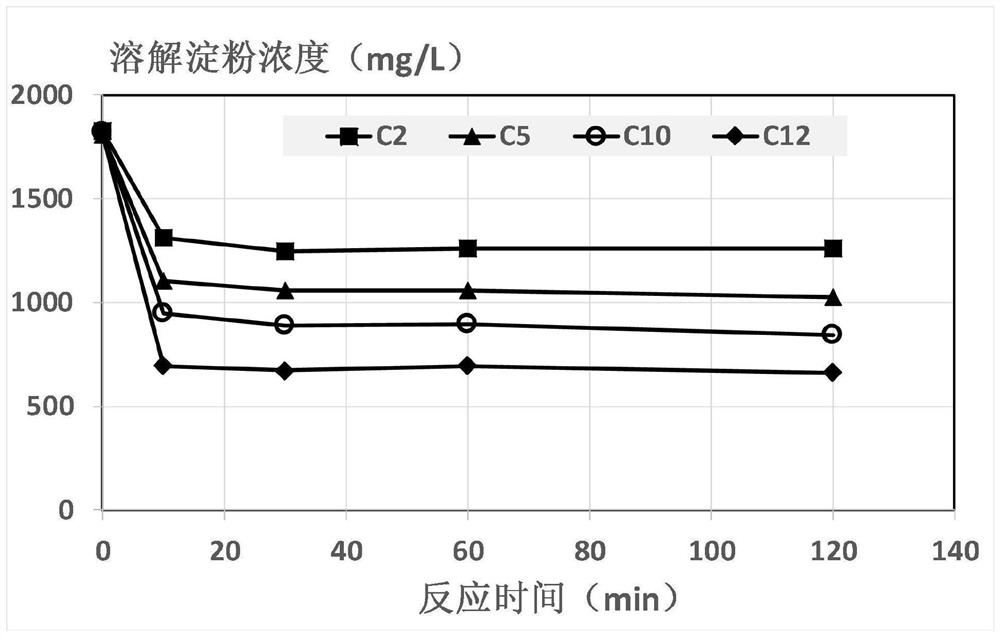

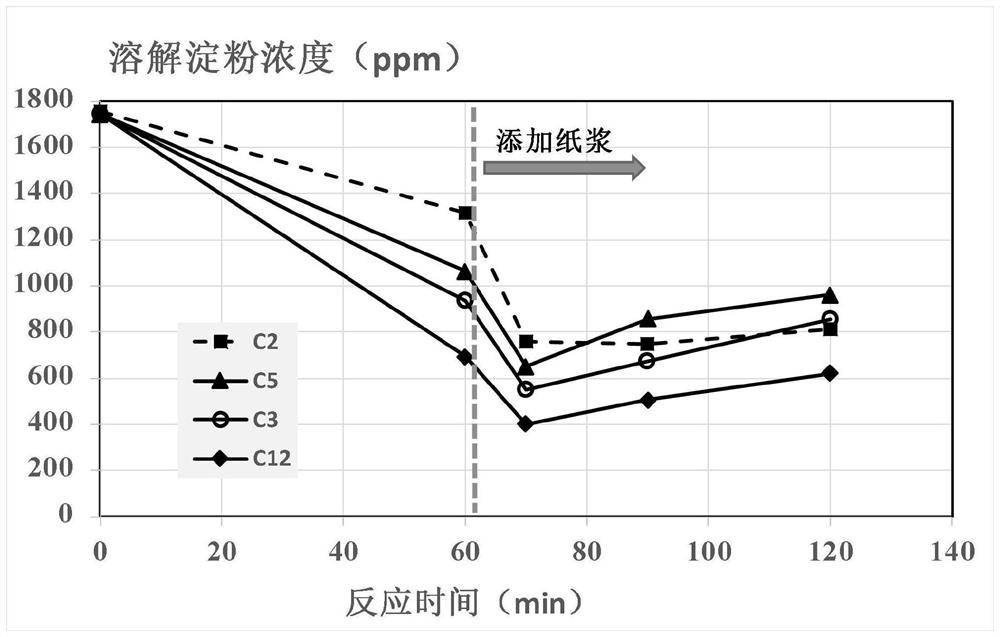

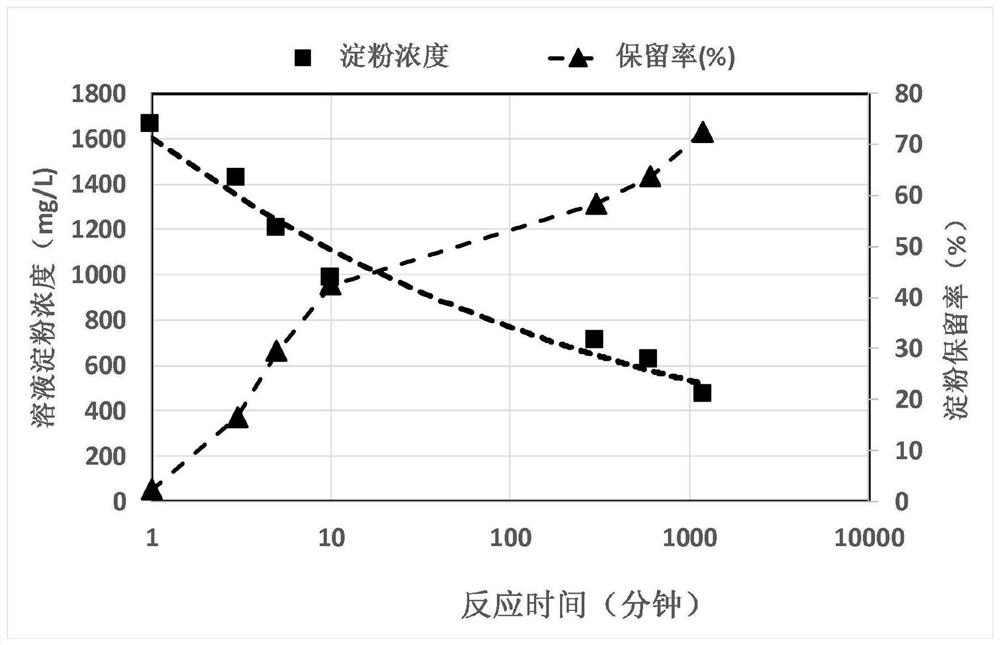

[0329] The impact of embodiment 2 reaction time on starch binding reaction

[0330] Experimental steps of starch reaction: (1) take corn starch sample and prepare 7% "standard starch solution"; (2) take appropriate amount of standard starch solution and dilute it with deionized water to a starch concentration of about 1800mg / L (or other required concentration) (3) Take 500mL of the prepared starch solution or OCC white water, place it in a beaker, and put it into a 45°C constant temperature water bath, and equilibrate to the specified temperature; (4) Add 30mg / L starch binder as required, When the reaction reaches 1, 3, 5, 10, 30, 60, 90, 120, 300, 600 and 1200 minutes, the sample is centrifuged (4000x g) for 5 minutes, and the supernatant is taken to test the starch content and COD concentration;

[0331] The test procedure of starch adsorption reaction time: steps (1)-(4) are the same as above, (5) when the starch reaction reaches 60 minutes, add 3% chemical pulp (BKP) accor...

Embodiment 3

[0337] Embodiment 3 Reaction temperature is to the influence of starch binding reaction and the adsorption effect of modified starch

[0338] Experimental steps: (1) Take corn starch samples to prepare 7% "standard starch solution"; (2) Take an appropriate amount of standard starch solution and add deionized water to dilute to a starch concentration of about 600mg / L; (3) Take the prepared starch solution 500mL, placed in a beaker, and put into a constant temperature water bath with the required test temperature preset, and equilibrated to the specified temperature; (4) According to the requirements of the test, add 30mg / L cationic starch binder C7 and react for 60 minutes to obtain Modified starch solution; (5) sample centrifugation (4000x g) for 5 minutes, get the supernatant to test starch content and COD concentration; (6) add chemical pulp (BKP ) (Note: The amount of starch binder is equivalent to 1000g / T dry pulp), keep stirring; (7) React for 10 minutes, take the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com