Paper-based device based on moving valve and molecular imprinting technology, and manufacturing method and application thereof

A technology of molecular imprinting technology and production method, which is applied in the field of paper-based devices, can solve the problems of strict storage conditions, cumbersome washing process, and long reaction time, and achieve the effects of reducing washing procedures, reducing costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for manufacturing a paper-based device based on a moving valve and molecular imprinting technology, comprising the following steps:

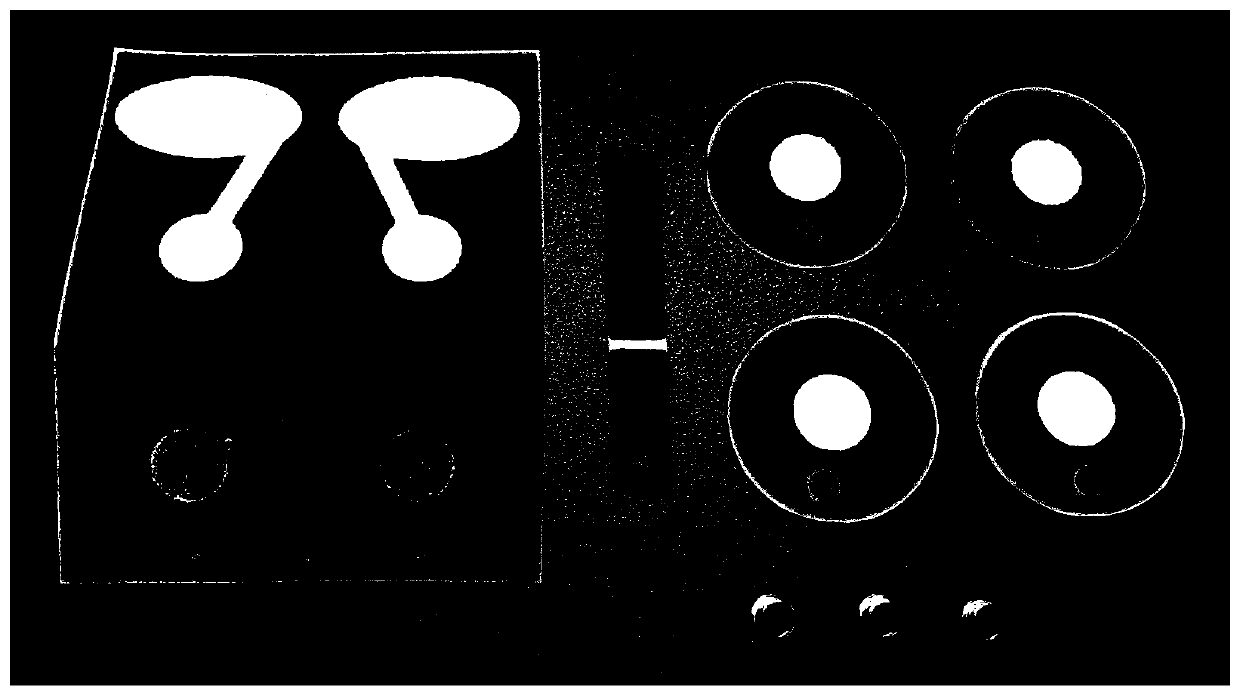

[0040] (1.1) Pattern design: use Adobe illustrator drawing software to design 4 kinds of chip patterns (see figure 1 ), which are respectively a working electrode part, four counter / reference electrode parts, a washing liquid recovery part, and a moving valve.

[0041] And requires the working electrode part (see figure 2 ) is 50mm×25mm in size, has two circular sample pools with a diameter of 9mm, a material addition pool with a diameter of 5mm, two disconnected channels pointing to the two sample pools with a width of 2mm, and three rivet holes; washing liquid The size of the recovery part is 40mm×50mm, connected with the working electrode part, and has two washing and drainage hydrophilic channels; the counter / reference electrode part is circular, with a diameter of 24mm, and the center position has a hydrophilic area of t...

Embodiment 2

[0049] A paper-based device based on a moving valve and molecular imprinting technology prepared in Example 1 is used for qualitative and quantitative analysis of cancer precursor antigen tumor markers in human serum, specifically including the following steps:

[0050] (2.1) Select cancer blank antigen tumor markers according to the type of tumor that needs to be diagnosed, and make a paper-based device based on moving valve and molecular imprinting technology that can detect biomarkers;

[0051] (2.2) First, close the counter / reference electrode part, the moving valve, and the washing liquid recovery part, so that they are away from the working electrode part. Add 5 μL serum sample dropwise to the sample cell of the working electrode part, and after equilibrating at room temperature for 10 minutes, fold the washing liquid recovery part to fit the working electrode part, and wash the sample cell with 10 mM, pH=7.4 PBS buffer solution 3 over, to remove interfering substances; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com