Proton exchange membrane fuel cell metal bipolar plate

A metal bipolar plate, proton exchange membrane technology, applied in fuel cells, fuel cell components, circuits, etc., can solve the problems of uneven flow distribution, excessive internal stress release cooling liquid flow resistance, etc. Too high, the effect of reducing the distribution area and reducing the flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

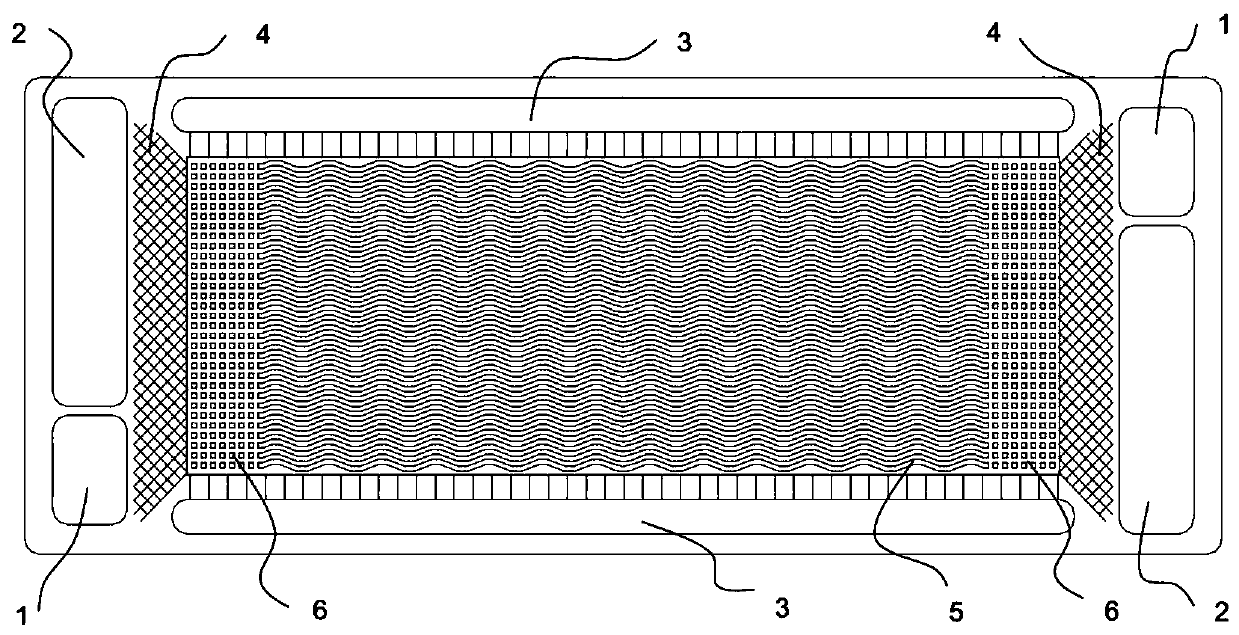

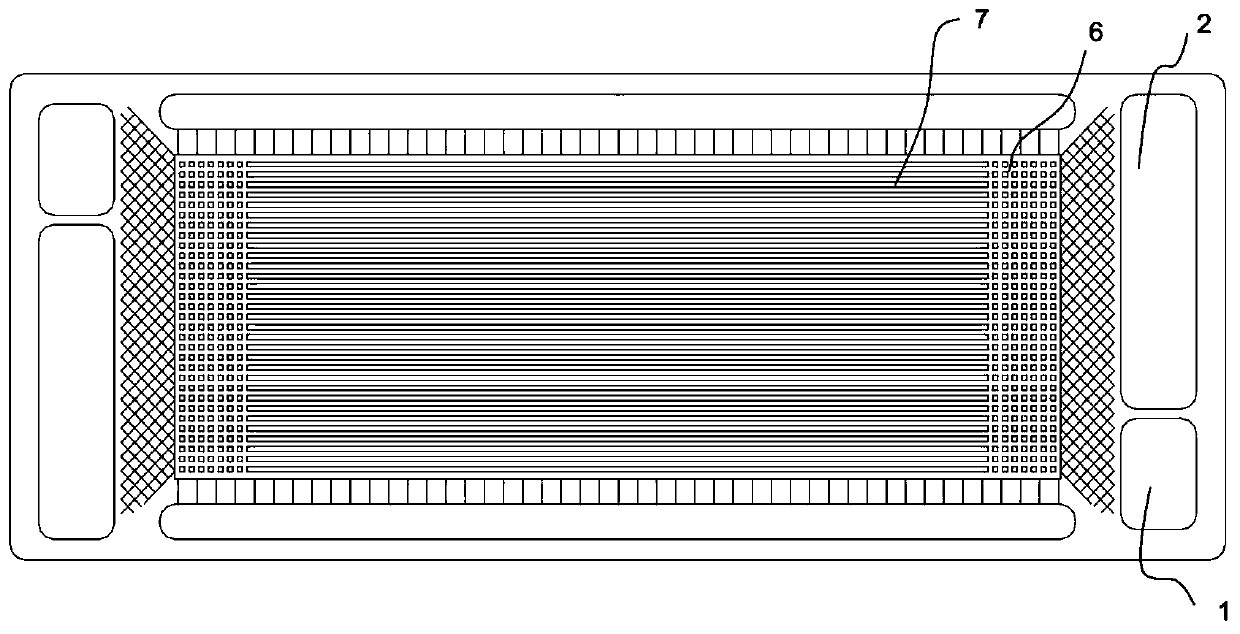

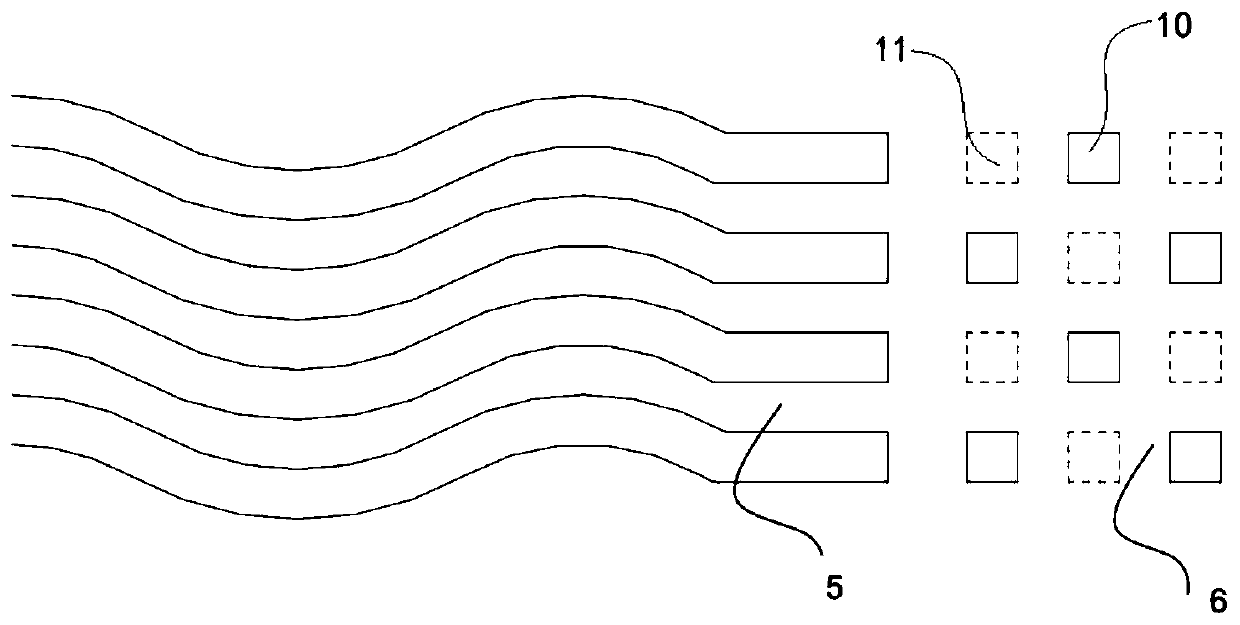

[0034] The proton exchange membrane fuel cell metal bipolar plate provided by the present invention is based on the fact that the flow field structure of the existing bipolar plate is consistent and continuously designed, and convex points and concave points are arranged at both ends of the continuous flow field structure, so as to A discontinuous flow field region structure is formed, which solves the problem of elastic deformation and fracture caused by local internal stress concentration during the preparation and stamping of the bipolar plate. In addition, the proton exchange membrane fuel cell metal bipolar plate provided by the present invention forms a cooling medium flow channel between the convex points and the concave points of the two concave-convex structures arranged oppositely, which overcomes the problem caused by the bipolar plate placed in the vertical direction. Excessive coolant flow resistance causes uneven flow distribution.

[0035] see figure 1 and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com