Egg cleaning and disinfecting method based on ultrasonic cooperated micro-nano bubble technology

A technology of micro-nano bubbles and eggs, which is applied in food ultrasonic treatment, poultry industry, food science, etc., can solve the problems of incomplete sterilization, damaged eggs, and long sterilization time, so as to improve the cleaning and disinfection efficiency, shorten the time and shorten the sterilization time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

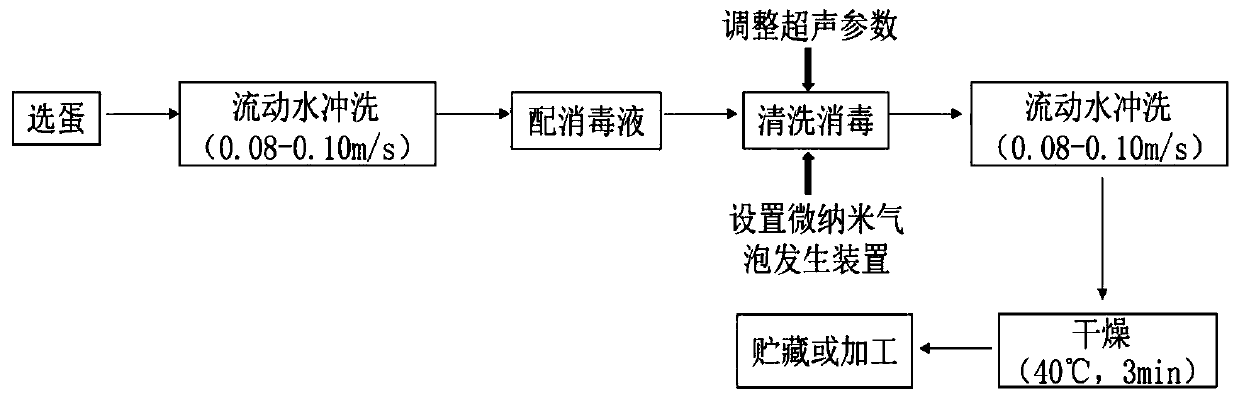

[0031] Use a combination of manual and mechanical methods to remove damaged and small cracked eggs and old eggs;

[0032] Use flowing water with a flow rate of 0.08m / s to 0.10m / s to wash away the feces, weeds, feathers, soil, etc. that are easy to remove on the surface of the eggshell. The cleaning time is 60s to reduce the subsequent disinfection and sterilization load;

[0033] Absorb 0.83 mL of 30% hydrogen peroxide, and prepare 0.5% hydrogen peroxide disinfectant with 50 mL of sterile water;

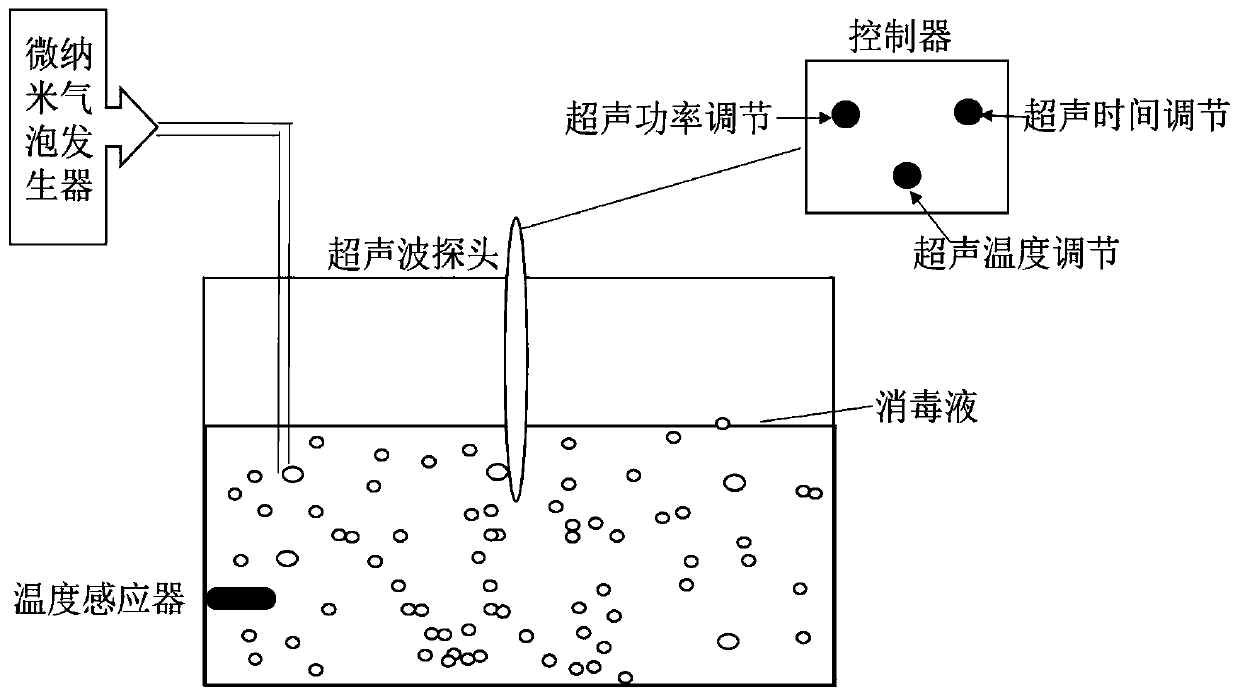

[0034] Add 2 g of citric acid and 5 g of disodium hydrogen phosphate to the disinfectant in sequence, dilute the prepared disinfectant stock solution at a ratio of 1:1000, place the compound disinfectant in an ultrasonic cleaning tank, set the ultrasonic temperature to 20°C, and ultrasonically The power is 50W, and the ultrasonic time is 20s, so that the components in the disinfectant are uniform and stable in the hydrogen peroxide system.

[0035] Soak the eggs in the disinfectant,...

Embodiment 2

[0038] Use a combination of manual and mechanical methods to remove damaged and small cracked eggs and old eggs;

[0039] Use flowing water with a flow rate of 0.08m / s to 0.10m / s to wash away the feces, weeds, feathers, soil, etc. that are easy to remove on the surface of the eggshell. The cleaning time is 60s to reduce the subsequent disinfection and sterilization load;

[0040] Absorb 3.3 mL of 30% hydrogen peroxide, and prepare 2% hydrogen peroxide disinfectant with 50 mL of sterile water;

[0041] Add 5g of citric acid and 2.5g of trisodium phosphate to the disinfectant in sequence, dilute the stock solution of the disinfectant at a ratio of 1:1000, place the compound disinfectant in the ultrasonic cleaning tank, set the ultrasonic temperature to 40°C, and the ultrasonic power to 60W. The ultrasonic time is 30s, so that the components in the disinfectant are uniform and stable in the hydrogen peroxide system.

[0042] Soak the eggs in the disinfectant solution, start the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com