Sintering flue gas desulphurization residue processing method

A technology for sintering flue gas and treatment method, applied in cement production and other directions, can solve the problems of low investment and production cost of production line, difficulty in comprehensive treatment and resource utilization, etc., to improve resource utilization rate, low production cost and stable composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

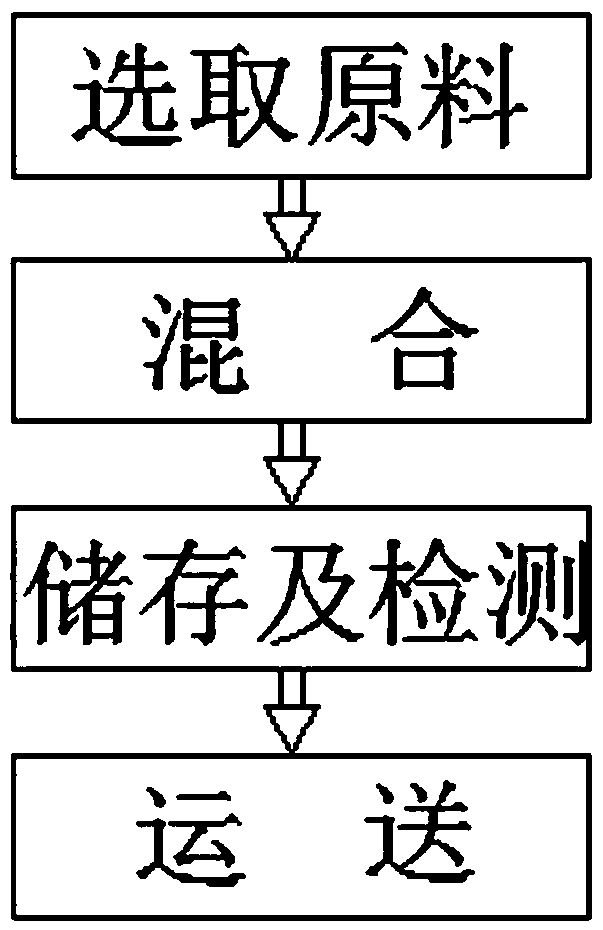

[0027] See figure 1 , a method for processing sintered flue gas desulfurization slag, comprising:

[0028] Select raw materials, and use weighing equipment to select appropriate amounts of sintering desulfurization slag, steelmaking LT ash, steelmaking OG mud and converter secondary ash according to the proportion. Each raw material has a different chemical composition, specifically;

[0029]

[0030] The selected raw materials are put into the silo with the feeding port through the feeding machine respectively. There is a weight valve at the bottom of the feeding port. The weight valve opens the feeding port according to the proportion, and the raw materials fall into the conveyor belt according to the proportion; The selected sintering desulfurization slag, steelmaking LT ash, steelmaking OG mud and converter secondary ash are sent to the mixer with transportation equipment to fully mix the finished product. The mixing time of various raw materials in the mixer is 2 to 3 ...

Embodiment 2

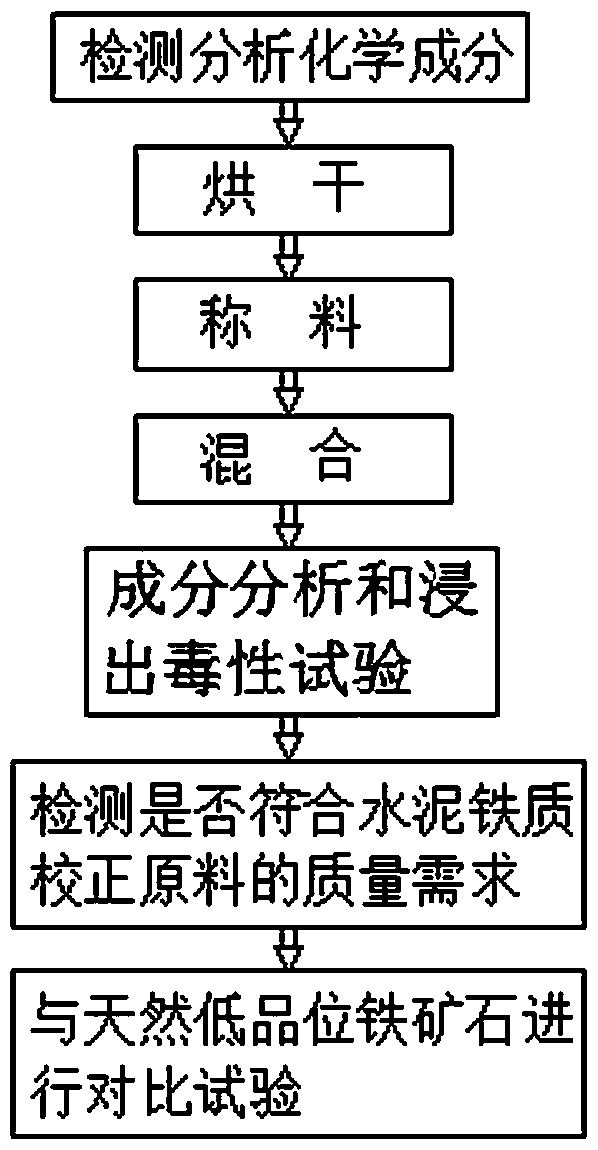

[0033] See figure 2 , a test method for using sintered flue gas desulfurization slag as raw material for correcting cement iron quality;

[0034] Step 1: Detect and analyze the chemical composition of sintering flue gas desulfurization slag and steelmaking LT ash, steelmaking OG mud and converter secondary ash produced in the process of iron and steel smelting;

[0035] Step 2: drying steelmaking OG mud and sintering flue gas desulfurization slag;

[0036] Step 3: Weigh the following raw materials: 100kg of sintering flue gas desulfurization slag, 100kg of steelmaking LT ash, 200kg of steelmaking OG mud, and 50kg of converter secondary ash;

[0037] Step 4: Add the above four materials and a certain proportion of water into a small powerful mixer and mix;

[0038] Step 5: Conduct component analysis and leaching toxicity test on the mixture;

[0039] Step 6: After testing, Fe in the mixture 2 o 3 The content is 63.24%, SO 3 The content is 1.40%, and the moisture content ...

Embodiment 3

[0042] See image 3 , a method for using sintered flue gas desulfurization slag as raw material for correcting iron quality of cement;

[0043] Step 1: drying steelmaking OG mud and sintering flue gas desulfurization slag through a hot blast stove;

[0044] Step 2: Pour the sintering flue gas desulfurization slag and steelmaking LT ash, steelmaking OG mud and converter secondary ash produced in the process of iron and steel smelting into four feed bins with feeding ports;

[0045]Step 3: Controlled by the weighing belt, feed materials according to the following mass percentages: sintering flue gas desulfurization slag 20-25%, steelmaking LT ash 20-25%, steelmaking OG mud 40-45%, converter secondary ash 10% ~15%;

[0046] Step 4: Add various raw materials into the plow mixer mixer in turn for full mixing, and add a certain proportion of water during the mixing process;

[0047] Step 5: Transport the mixed material to the finished product silo through the belt;

[0048] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com