Method for preparing ceramsite filter material by synergistically utilizing solid waste

A ceramsite filter material and filter material technology, applied in separation methods, chemical instruments and methods, applications, etc., can solve the problems of not using high-alumina fly ash, achieve wide application range, large specific surface area, and improve solid waste The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

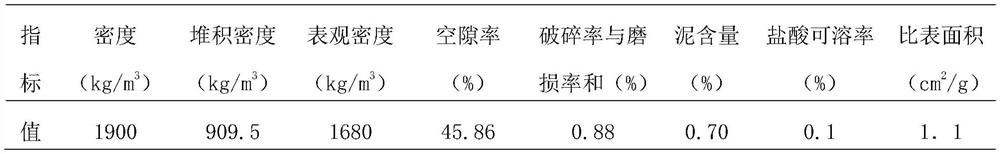

Embodiment 1

[0046] 1.1 Preparation method

[0047] The invention provides a method for preparing ceramsite filter material by the synergistic utilization of solid waste, comprising the following processing steps:

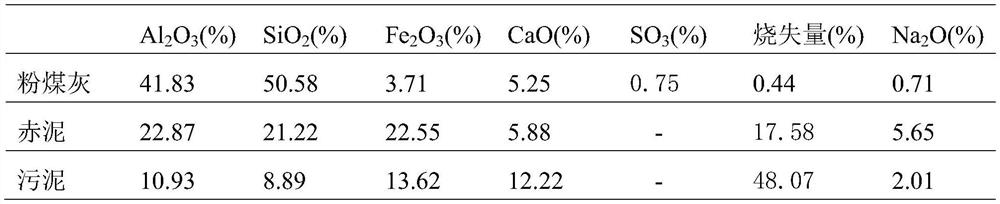

[0048] S1 raw material pretreatment, the preparation raw materials of ceramsite filter material are high-alumina fly ash, red mud and sludge, after drying the red mud and sludge, grinding to obtain red mud and sludge powder, high-alumina powder coal The particle size of ash is 45μm sieve balance ≤ 35%, the red mud and sludge raw materials are dried and ground to prepare powder moisture content ≤ 5%, particle size ≤ 100μm;

[0049] S2 is batched according to 70% high-alumina fly ash, 13% red mud and 11% sludge, and the prepared mixture is put into the mixer and stirred evenly;

[0050] S3 transports the evenly stirred material to the disc granulator, and performs water spray granulation to prepare ceramsite filter material raw balls. The liquid used for water spray granulation ...

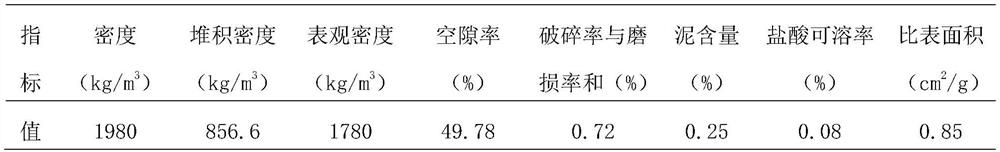

Embodiment 2

[0058] 2.1 Preparation method

[0059] The invention provides a method for preparing ceramsite filter material by the synergistic utilization of solid waste, comprising the following processing steps:

[0060] S1 raw material pretreatment, the preparation raw materials of ceramsite filter material are high-alumina fly ash, red mud and sludge, after drying the red mud and sludge, grinding to obtain red mud and sludge powder, high-alumina powder coal The particle size of ash is 45μm sieve balance ≤ 35%, the red mud and sludge raw materials are dried and ground to prepare powder moisture content ≤ 5%, particle size ≤ 100μm;

[0061] S2 is batched according to 65% high-alumina fly ash, 15% red mud and 20% sludge, and the prepared mixture is put into the mixer and stirred evenly;

[0062] S3 transports the evenly stirred material to the disc granulator, and performs water spray granulation to prepare ceramsite filter material raw balls. The liquid used for water spray granulation ...

Embodiment 3

[0070] 3.1 Preparation method

[0071] The invention provides a method for preparing ceramsite filter material by the synergistic utilization of solid waste, comprising the following processing steps:

[0072] S1 raw material pretreatment, the preparation raw materials of ceramsite filter material are high-alumina fly ash, red mud and sludge, after drying the red mud and sludge, grinding to obtain red mud and sludge powder, high-alumina powder coal The particle size of ash is 45μm sieve balance ≤ 35%, the red mud and sludge raw materials are dried and ground to prepare powder moisture content ≤ 5%, particle size ≤ 100μm;

[0073] S2 is batched according to 80% high-alumina fly ash, 5% red mud and 15% sludge, and the prepared mixture is put into the mixer and stirred evenly;

[0074] S3 transports the evenly stirred material to the disc granulator, and performs water spray granulation to prepare ceramsite filter material raw balls. The liquid used for water spray granulation i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com