Treatment method of rotary hearth furnace metallized pellet undersize powder

A technology of metallized pellets and a treatment method, which is applied in the field of iron and steel smelting waste utilization, can solve the problems of great influence on blast furnace production, blockage of dust collector pipes, and many restrictions on use, so as to improve the utilization rate of solid waste resources and improve The effect of using efficiency and production line investment is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

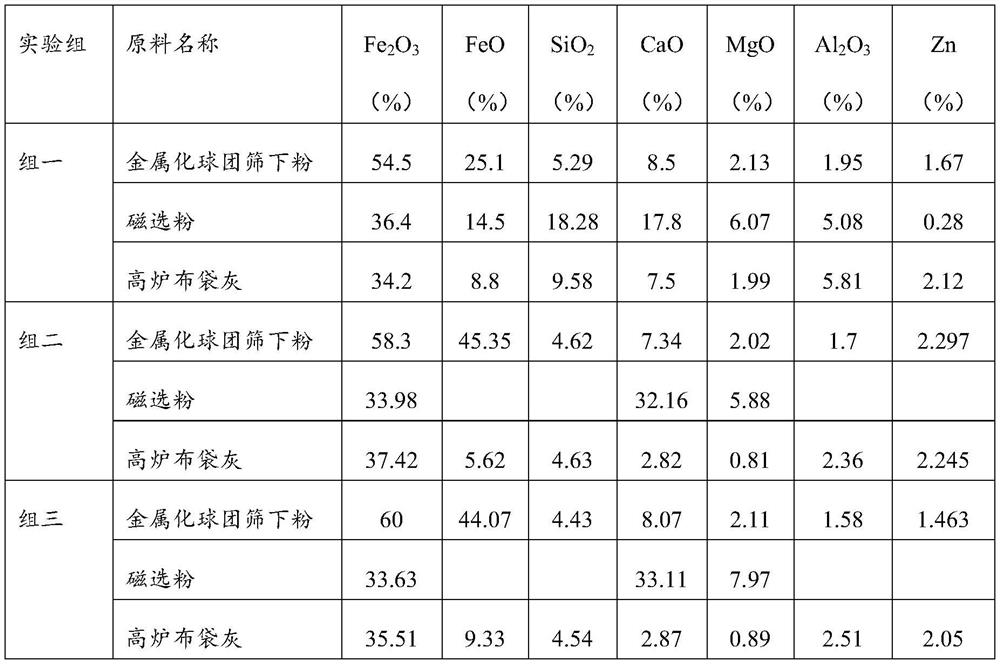

[0038] A method for processing metallized pellet sieve powder of a rotary hearth furnace, comprising: selecting raw materials, sieving powder according to metallized pellets: magnetic separation powder: blast furnace bag ash at a ratio of 3:1:1, and using weighing equipment Select an appropriate amount of metallized pellet sieve powder, magnetic separation powder, and blast furnace bag ash,

[0039] Three groups of different raw materials with different chemical composition content will be selected, all adopt the following experimental steps:

[0040] The selected raw materials are put into the silo with the feeding port through the feeding machine respectively. There is a weight valve at the bottom of the feeding port. The weight valve opens the feeding port according to the proportion, and the raw materials fall into the conveyor belt according to the proportion; The selected metallized pellet under-screen powder, magnetic separation powder, and blast furnace bag ash are sen...

Embodiment 2

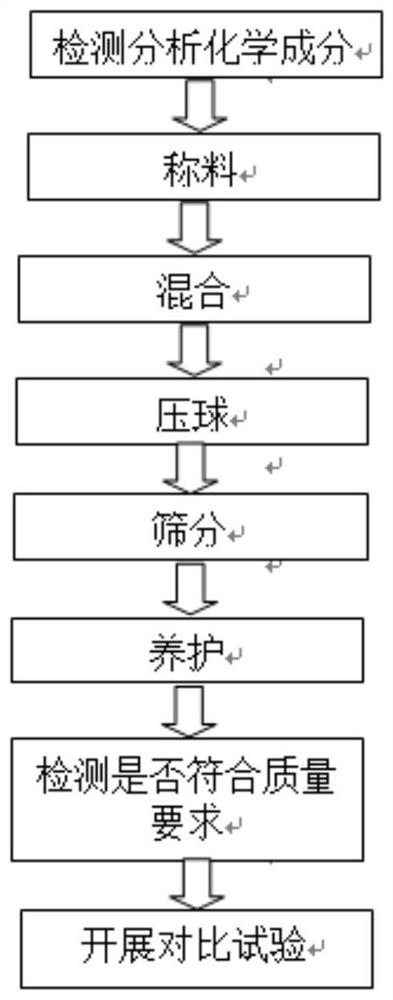

[0044] See figure 1 , a method for testing the powder under the sieve of the metallized pellets of the rotary hearth furnace as a raw material for the converter;

[0045] Step 1: all adopt the raw materials whose chemical composition content is experimental group one;

[0046] Step 2: Weigh the following three groups of raw materials with different mass mixing ratios of 3:1:1 for testing;

[0047] Experimental group four: Rotary hearth furnace metallized pellet under-sieve powder 600kg, magnetic separation powder 200kg, blast furnace bag ash 200kg;

[0048] Experimental group five: Rotary hearth furnace metallized pellet sieve powder 300kg, magnetic separation powder 100kg, blast furnace bag ash 100kg

[0049] Experimental group 6: Rotary hearth furnace metallized pellet under-sieve powder 150kg, magnetic separation powder 75kg, blast furnace bag ash 75kg;

[0050] Step 3: Add the above three materials, binder and a certain proportion of water into a small powerful mixer an...

Embodiment 3

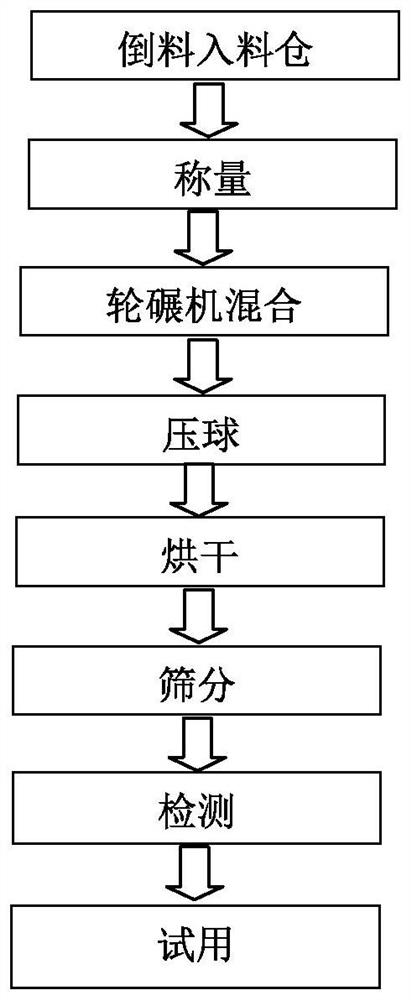

[0058] See figure 2 , a method for using the metallized pellet undersize powder of a rotary hearth furnace as a raw material for a converter;

[0059] Step 1: Use the three raw materials of metallized pellet sieve powder, magnetic separation powder and blast furnace bag ash whose chemical composition content is experimental group 1 and pour them into three hoppers with feeding ports;

[0060] Step 2: Controlled by the weighing belt, feed materials according to the following mass percentages: 55-65%, magnetic separation powder 15-25%, blast furnace bag ash 10-30%;

[0061] Step 3: Put various raw materials into the wheel mill in turn for full mixing, and add a certain proportion of binder and water during the mixing process;

[0062] Step 4: Convey the mixed material to the double-roller briquetting machine through the belt;

[0063] Step 5: Send the pressed pellets into the dryer for drying, and the dryer uses the waste heat of the flue gas from the rotary hearth furnace as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com