A preparation method of polycrystalline bulk material for optical wavelength conversion

A technology of optical wavelength conversion and bulk materials, applied in the field of preparation of polycrystalline bulk materials, can solve the problems of complex process, unfavorable large-scale industrial production and application, and limited improvement effect, and achieve uniform light color, process simplification and The effect of improving the economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

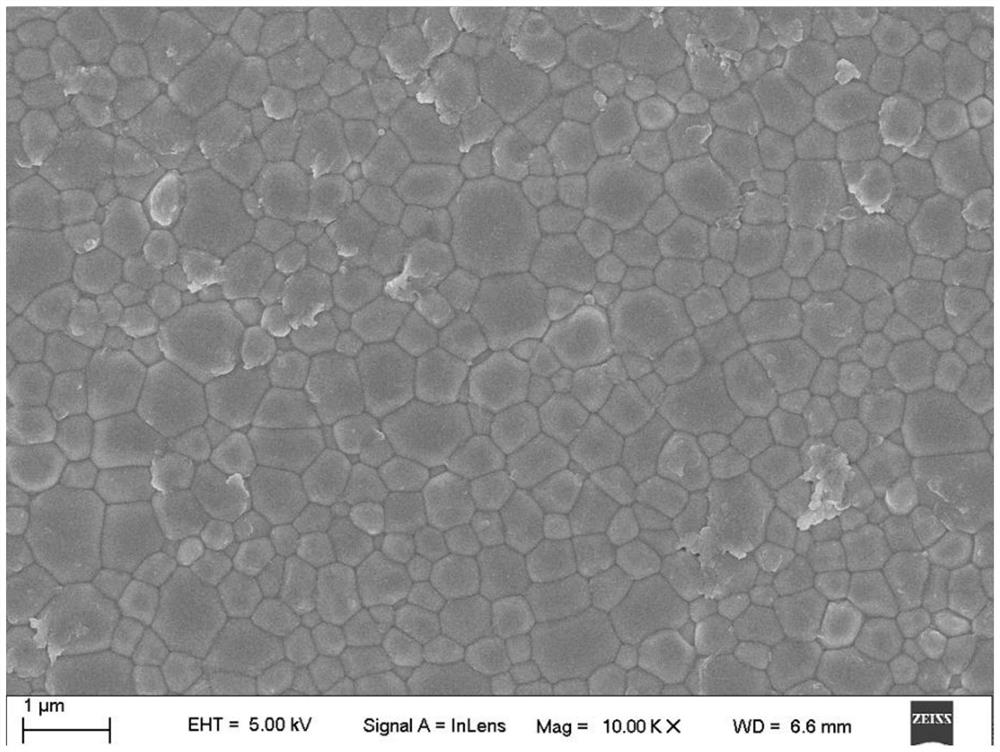

[0033] The invention is a method for preparing a polycrystalline bulk material for light wavelength conversion, comprising the following steps:

[0034] 1) Use aluminum oxide, yttrium oxide, and cerium oxide as raw materials to weigh according to the stoichiometric ratio of the garnet structure. According to the mass ratio of raw materials: alcohol: balls is 1:1.5:5, ball mill and mix evenly, and dry to obtain the initial raw material powder body;

[0035] 2) The initial raw material powder is sieved with a 50-micron sieve to obtain coarse and fine powders with different particle sizes. After separation, the powder for molding is obtained by combining the fine particle size powder and the coarse particle size powder at a mass ratio of 70%:30%;

[0036] 3) The powder for molding is firstly pressed into a block by dry pressing and then by cold isostatic pressing, the applied pressure is 200MPa, and degreasing in an oxygen atmosphere at 600°C to obtain a block green body;

[00...

Embodiment 2

[0039] The invention is a method for preparing a polycrystalline bulk material for light wavelength conversion, comprising the following steps:

[0040] 1) Use aluminum oxide, yttrium oxide, and cerium oxide as raw materials to weigh according to the stoichiometric ratio of the garnet structure. According to the mass ratio of raw materials: alcohol: balls is 1:1.5:5, ball mill and mix evenly, and dry to obtain the initial raw material powder body;

[0041] 2) The initial raw material powder is sieved with an 80-micron sieve to obtain coarse and fine powders with different particle sizes. After separation, according to the combination of fine particle size powder and coarse particle size powder at a mass ratio of 80%: 20%, the powder for molding is obtained;

[0042] 3) The powder for molding is firstly pressed into a block by dry pressing and then by cold isostatic pressing, the applied pressure is 250MPa, and degreasing in an oxygen atmosphere at 700°C to obtain a block gree...

Embodiment 3

[0045] The invention is a method for preparing a polycrystalline bulk material for light wavelength conversion, comprising the following steps:

[0046] 1) Use aluminum oxide, yttrium oxide, and cerium oxide as raw materials to weigh according to the stoichiometric ratio of the garnet structure. According to the mass ratio of raw materials: alcohol: balls is 1:1.5:5, ball mill and mix evenly, and dry to obtain the initial raw material powder body;

[0047] 2) The initial raw material powder is sieved with a 100-micron sieve to obtain coarse and fine powders with different particle sizes. After separation, the powder for molding is obtained by combining fine particle size powder and coarse particle size powder at a mass ratio of 90%:10%;

[0048] 3) The powder for molding is firstly pressed into a block by dry pressing and then by cold isostatic pressing, the applied pressure is 250MPa, and degreasing in an oxygen atmosphere at 700°C to obtain a block green body;

[0049] 4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com