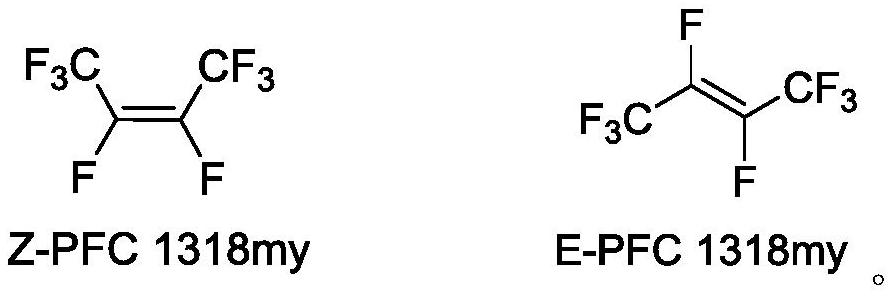

A kind of method for preparing octafluoro-2-butene

A technology of butene and tetrafluoroethane, which is applied in the field of preparation of fluorine-containing olefins, and can solve problems such as difficult availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

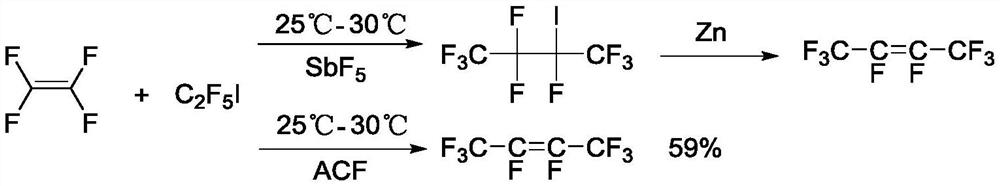

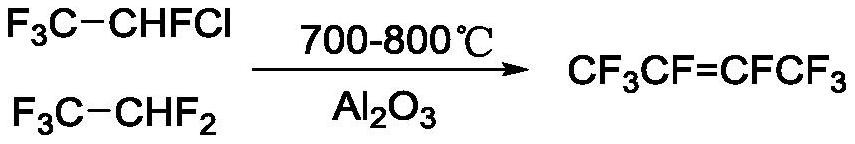

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The reaction in the presence of tetramethylethylenediamine, CuCl and DMF is illustrated.

[0047] Add 100g (1.37mol) of N,N-dimethylformamide, 12.8g (0.2mol) of 400-mesh copper powder, 23.2g (0.2 mol), cuprous chloride 1.0g (0.01mol), with high-purity N 2 Purge for 10 minutes, then pour 17.1g (0.1mol) of CFC-114a from the steel cylinder into the reactor, heat up to 80°C under mechanical stirring (300-500r / m), raise the pressure of the reactor to about 0.4MPa, and keep it warm for 12 hours , to end the reaction.

[0048] The reaction products include gas phase components and liquid phase components. According to GC-MS analysis, both gas phase components and liquid phase components contain 1,1,1,2,3,4,4,4-octafluoro-2- Butene, see Table 1 for details. In Table 1, the percentage of each compound is an area percentage, and impurities with an area percentage of less than 0.05% are not included in Table 1.

[0049] Table 1, embodiment 1 reaction product GC area percentage...

Embodiment 2

[0054] The reaction in the presence of ethylenediamine, CuCl and DMF is illustrated.

[0055] Add 100g (1.37mol) of N,N-dimethylformamide, 12.8g (0.2mol) of 400 mesh copper powder, 12.02g (0.2mol) of ethylenediamine, Cuprous chloride 1.0g (0.01mol), with high-purity N 2 Purge for 10 minutes, then pour 17.1g (0.1mol) of CFC-114a from the steel cylinder into the reactor, raise the temperature to 80°C under mechanical stirring (300-500r / m), and raise the pressure of the reactor to about 0.38MPa, and keep it warm for 12 hours . End the reaction.

[0056] The reaction products include gas phase components and liquid phase components. According to GC-MS analysis, both gas phase components and liquid phase components contain 1,1,1,2,3,4,4,4-octafluoro-2- Butene, see Table 2 for details. In Table 2, the percentage of each compound is an area percentage, and impurities with an area percentage of less than 0.05% are not included in Table 2.

[0057] Table 2, embodiment 2 reaction p...

Embodiment 3

[0062] The reaction in the presence of 2,2'-bipyridine, CuCl and DMF is illustrated.

[0063] Add 100g (1.37mol) of N,N-dimethylformamide, 12.8g (0.2mol) of 400-mesh copper powder, and 31.24g ( 0.2mol), cuprous chloride 1.0g (0.01mol), with high-purity N 2 Purge for 10 minutes, then pour 17.1g (0.1mol) of CFC-114a from the steel cylinder into the reactor, heat up to 80°C under mechanical stirring (300-500r / m), raise the pressure of the reactor to about 0.4MPa, and keep it warm for 12 hours , the reaction ends.

[0064] The reaction products include gas phase components and liquid phase components. According to GC-MS analysis, both gas phase components and liquid phase components contain 1,1,1,2,3,4,4,4-octafluoro-2- Butene, see Table 3 for details. In Table 3, the percentage of each compound is an area percentage, and impurities with an area percentage of less than 0.05% are not included in Table 3.

[0065] Table 3, embodiment 3 reaction product GC area percent

[0066] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com