Strip-shaped beef granules

A beef grain and beef technology, which is applied in the fields of climate change adaptation, food coating, food science, etc., can solve the problems of reducing the microbial activity, poor taste and taste of strip beef grains, and achieves the reduction of microbial activity and moderate spicyness. , strong aftertaste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

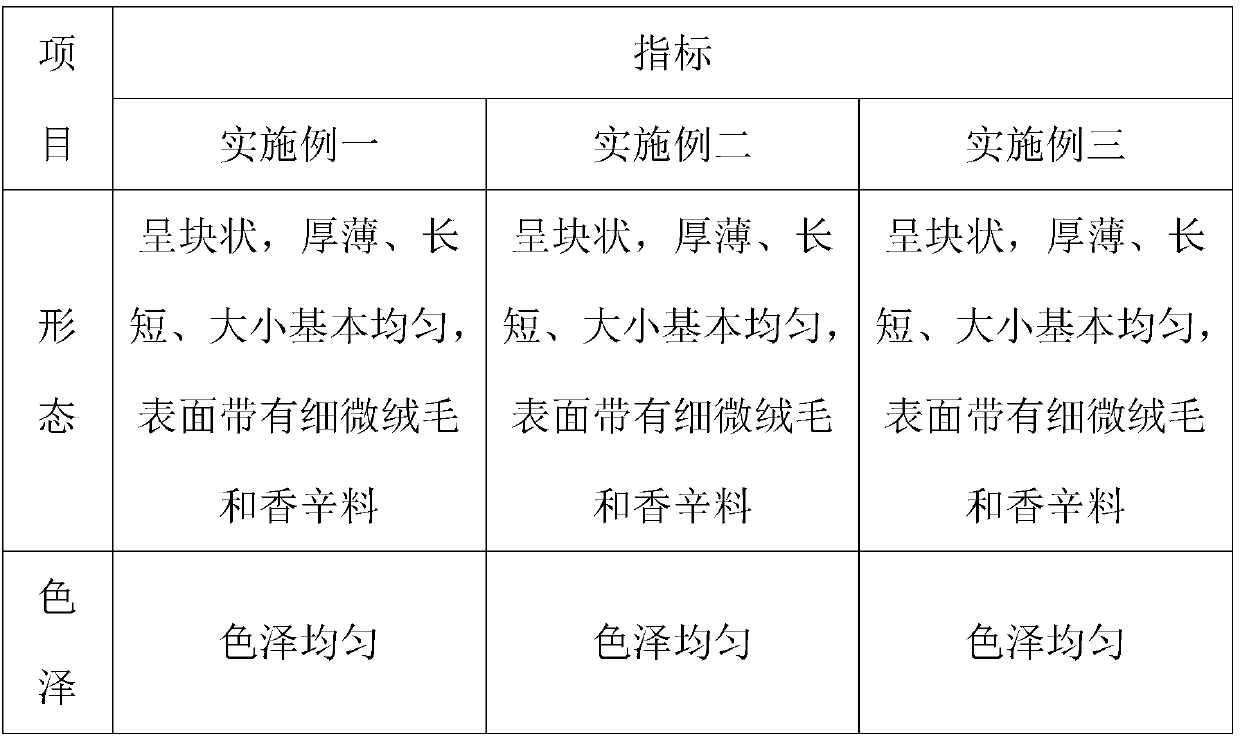

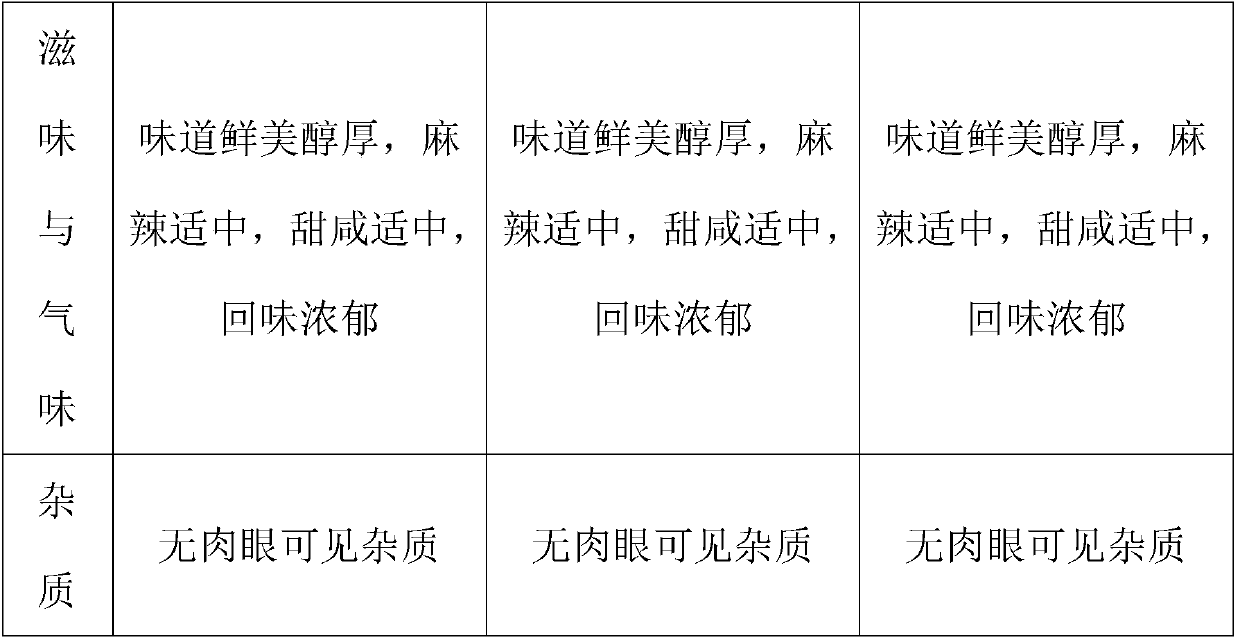

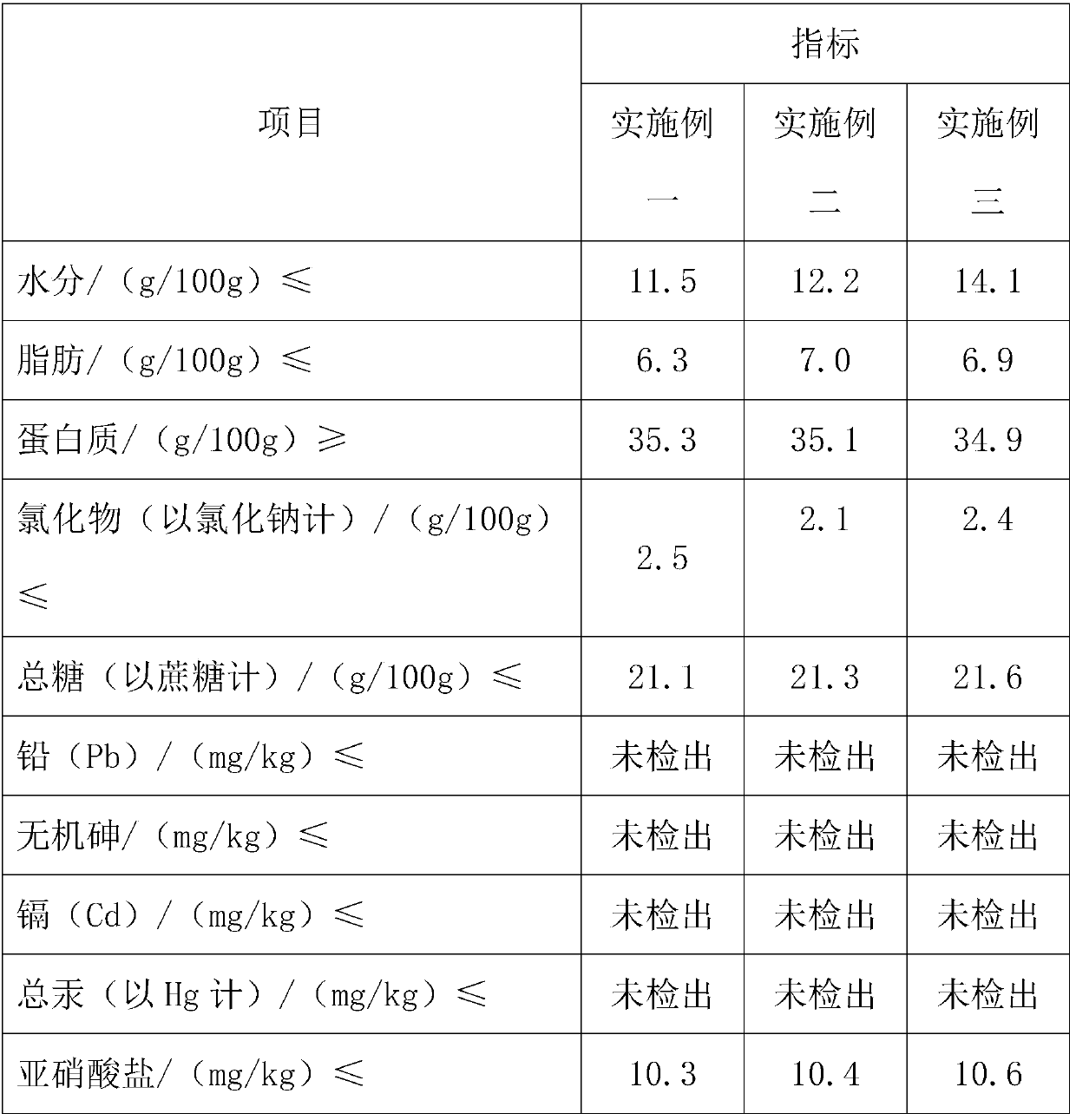

Examples

Embodiment 1

[0036] (1) Submerge 500 parts by mass of beef hindquarters in a saline solution with a mass fraction of 30% and a temperature of 30°C, take it out after immersion for 10 minutes, wash it with warm boiling water at 30°C for 3 times, drain the surface moisture, and then Wrap the beef hindquarters with plastic wrap, store them in a freezer at -18°C for 10 hours after quick freezing, and take them out to obtain sterilized beef hindquarters;

[0037] (2) Thaw the sterilized beef hindquarters prepared in step (1) in a microwave oven, remove the plastic wrap after thawing, and place the beef hindquarters on a clean plate covered with oil-absorbing paper , adding ice to keep fresh, so as to obtain pretreated beef hindquarters;

[0038] (3) Place the beef hindquarters prepared in step (2) on a meat cutting board covered with oil-absorbing paper, roll them with a rolling pin for 10 times, then turn the beef hindquarters over, and turn over the beef hindquarters after turning over. The ...

Embodiment 2

[0048] (1) Submerge 500 parts by mass of beef hindquarters in a saline solution with a mass fraction of 35% and a temperature of 37°C, take it out after immersion for 15 minutes, wash it with warm boiling water at 37°C for 4 times, drain the surface moisture, and then Wrap the beef hindquarters with plastic wrap, store them in a freezer at -18°C for 11 hours after quick freezing, and take them out to obtain sterilized beef hindquarters;

[0049] (2) Thaw the sterilized beef hindquarters prepared in step (1) in a microwave oven, remove the plastic wrap after thawing, and place the beef hindquarters on a clean plate covered with oil-absorbing paper , adding ice to keep fresh, so as to obtain pretreated beef hindquarters;

[0050] (3) Place the beef hindquarters prepared in step (2) on a meat cutting board covered with oil-absorbing paper, roll them with a rolling pin for 15 times, then turn the beef hindquarters over, and turn over the beef hindquarters after turning over. The ...

Embodiment 3

[0060] (1) Submerge 500 parts by mass of beef hindquarters in a saline solution with a mass fraction of 40% and a temperature of 40°C, take it out after immersion for 20 minutes, wash it with warm boiling water at 40°C for 5 times, drain the surface moisture, and then Wrap the beef hindquarters with plastic wrap, store them in a freezer at -18°C for 12 hours after quick freezing, and take them out to obtain sterilized beef hindquarters;

[0061] (2) Thaw the sterilized beef hindquarters prepared in step (1) in a microwave oven, remove the plastic wrap after thawing, and place the beef hindquarters on a clean plate covered with oil-absorbing paper , adding ice to keep fresh, so as to obtain pretreated beef hindquarters;

[0062] (3) Place the beef hindquarters prepared in step (2) on a meat cutting board covered with oil-absorbing paper, roll them with a rolling pin for 20 times, then turn the beef hindquarters over, and turn over the beef hindquarters after turning over. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com