Novel log multi-blade band saw equipment

A log and band saw technology, applied in the field of new round log multi-piece band saw equipment, can solve the problems of difficult control of cutting thickness, low cutting efficiency, wood waste, etc., to avoid cutting offset and wood waste, and work efficiency. High, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

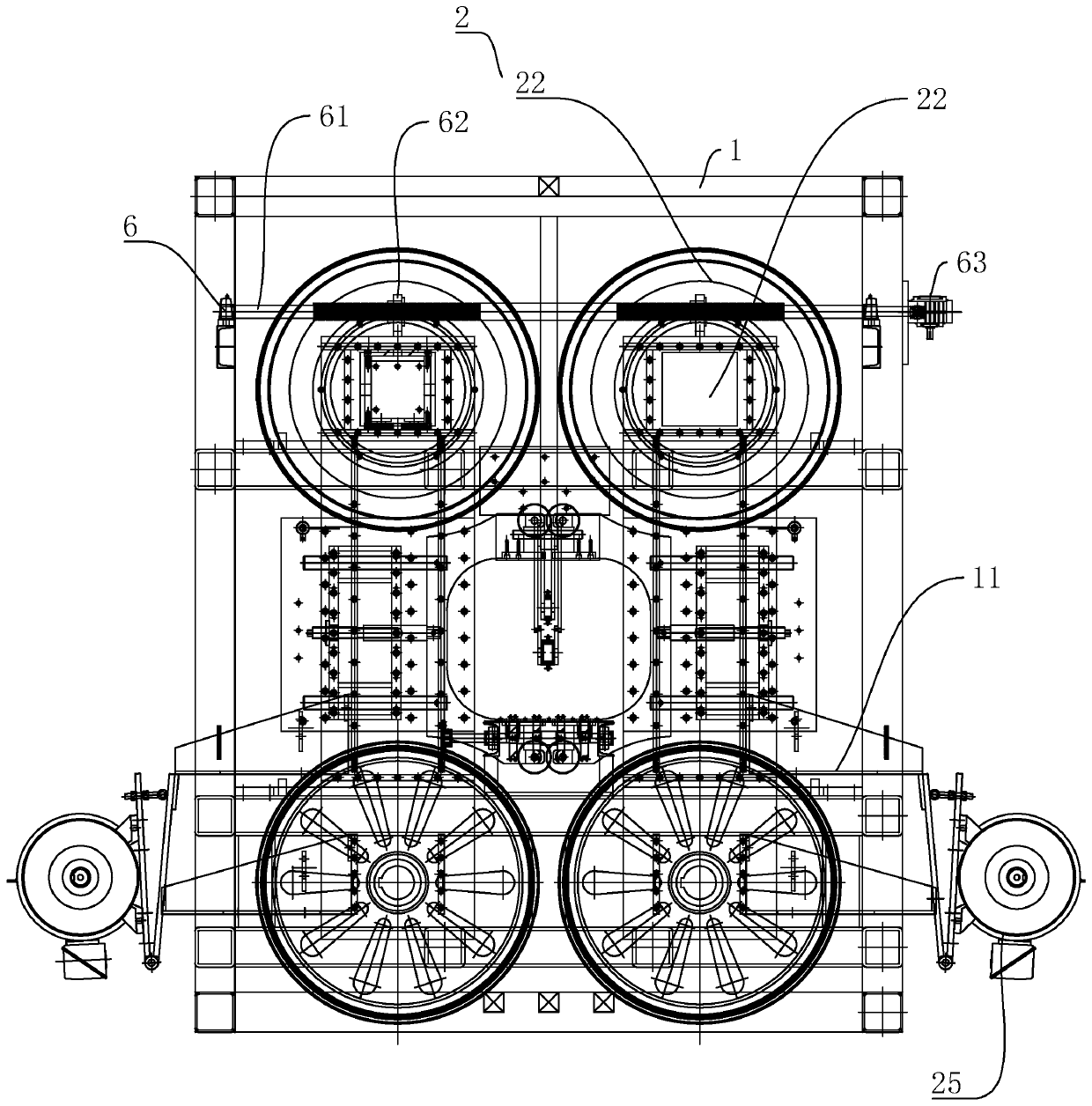

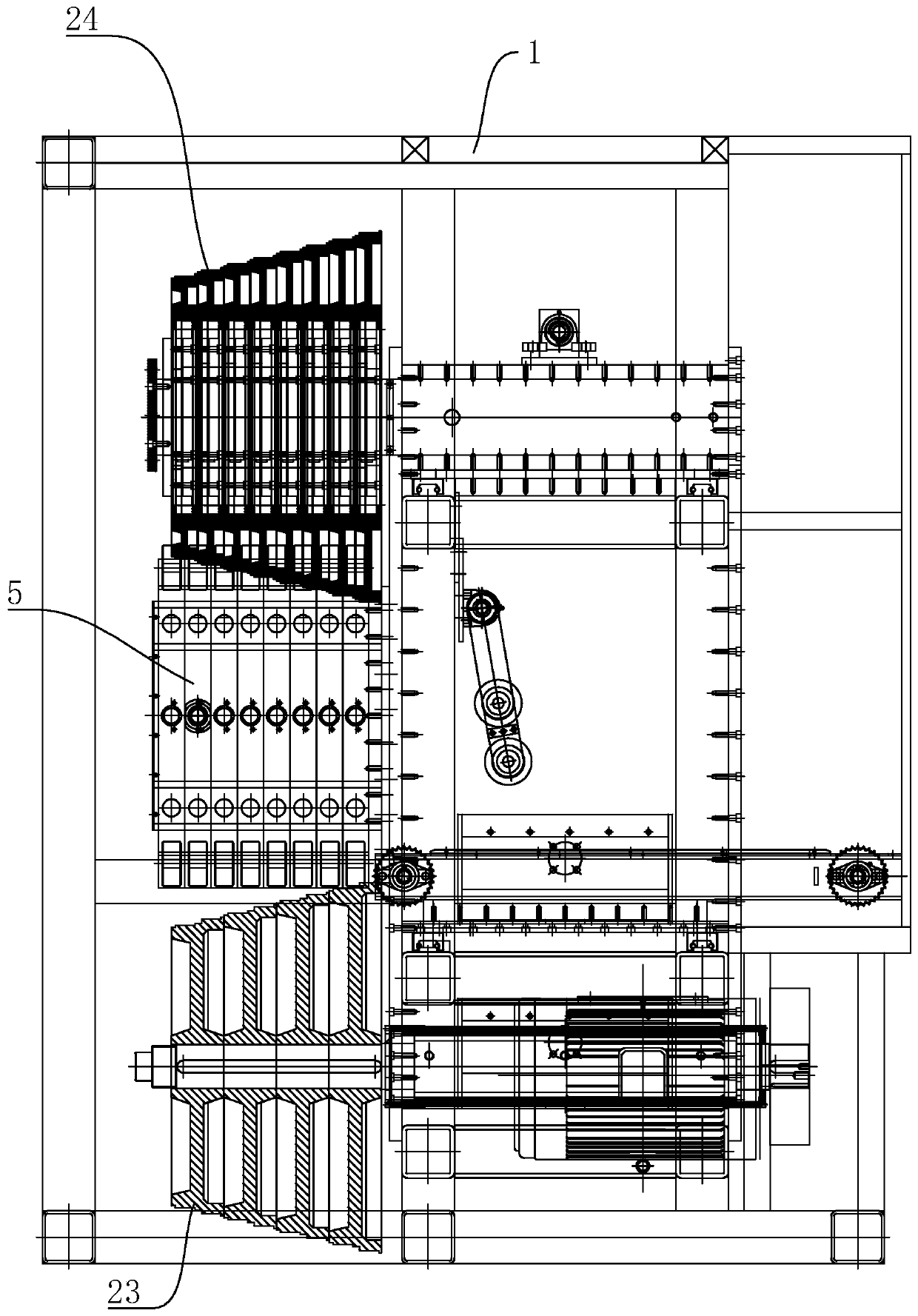

[0035] A new type of round wood multi-piece band sawing equipment provided in this embodiment has a structure such as figure 1 As shown, it includes an outer frame 1, an operating table 11 arranged in the outer frame 1, a cutting assembly 2 is provided in the middle of the outer frame 1, and the two sides of the cutting assembly 2 are respectively provided with feeding assemblies for feeding and discharging. 3 and discharge assembly 4.

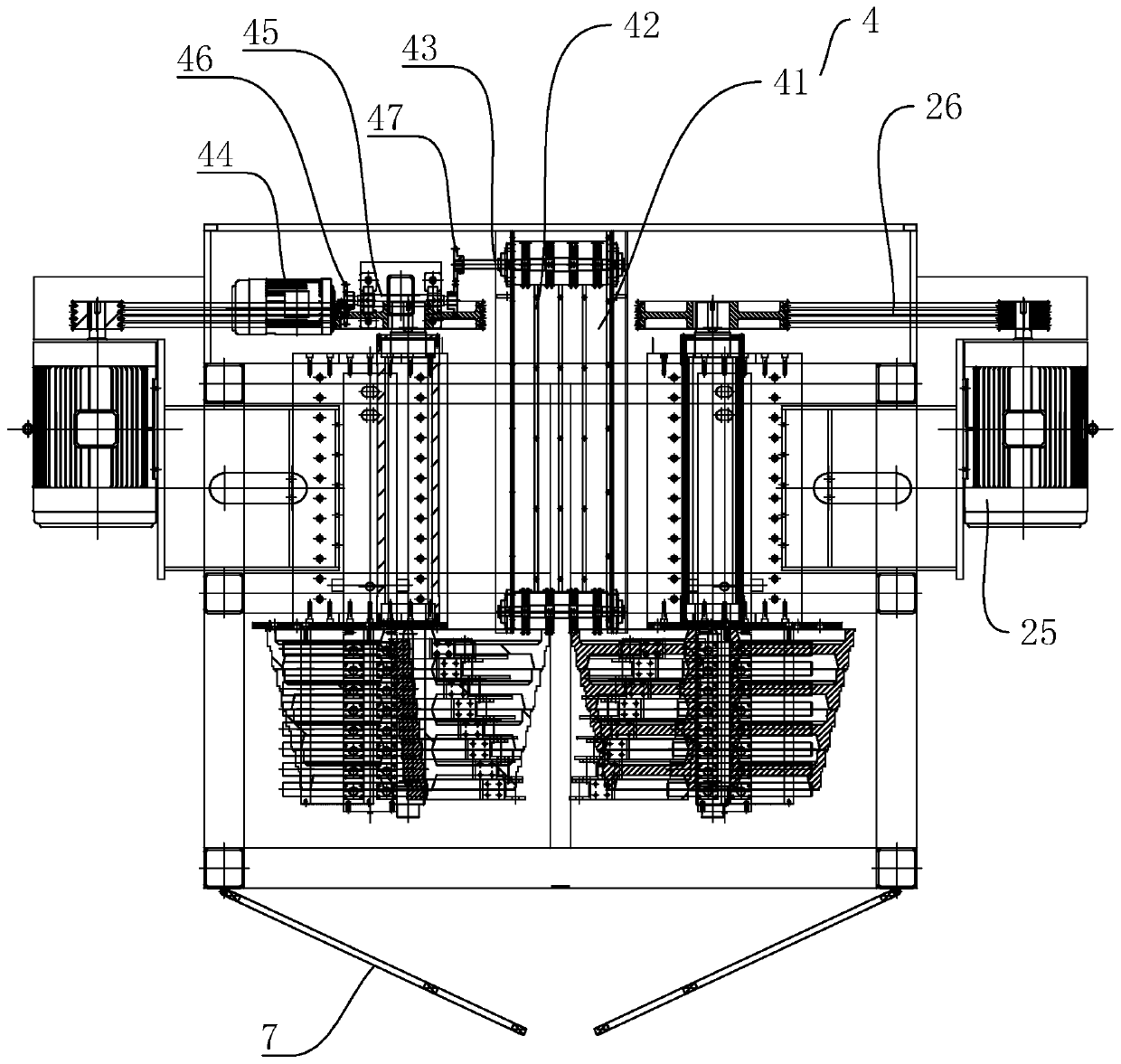

[0036] Such as Figure 1-3 As shown, the cutting assembly 2 includes two cutting seats 21 that are on the same straight line and whose spacing can be adjusted. The cutting seats 21 are provided with several cutting saw blades 22 that are parallel to each other. Saw blade guide mechanism 5 for spacing. The cutting seat 21 comprises two groups of the top and the bottom of the console 11. The cutting seat 21 below the console 11 is a saw blade driving disc 23, and the cutting saw blade 22 can be installed or not installed. The cutting seat 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com