Control method for off-highway vehicle electric drive system

An off-highway vehicle and control method technology, which is applied in the field of off-highway vehicle electric drive system control, can solve the problems of loss of traction, poor acceleration and deceleration performance, overcurrent and overvoltage of the entire vehicle, etc., and achieves high control accuracy and prevents traction. glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

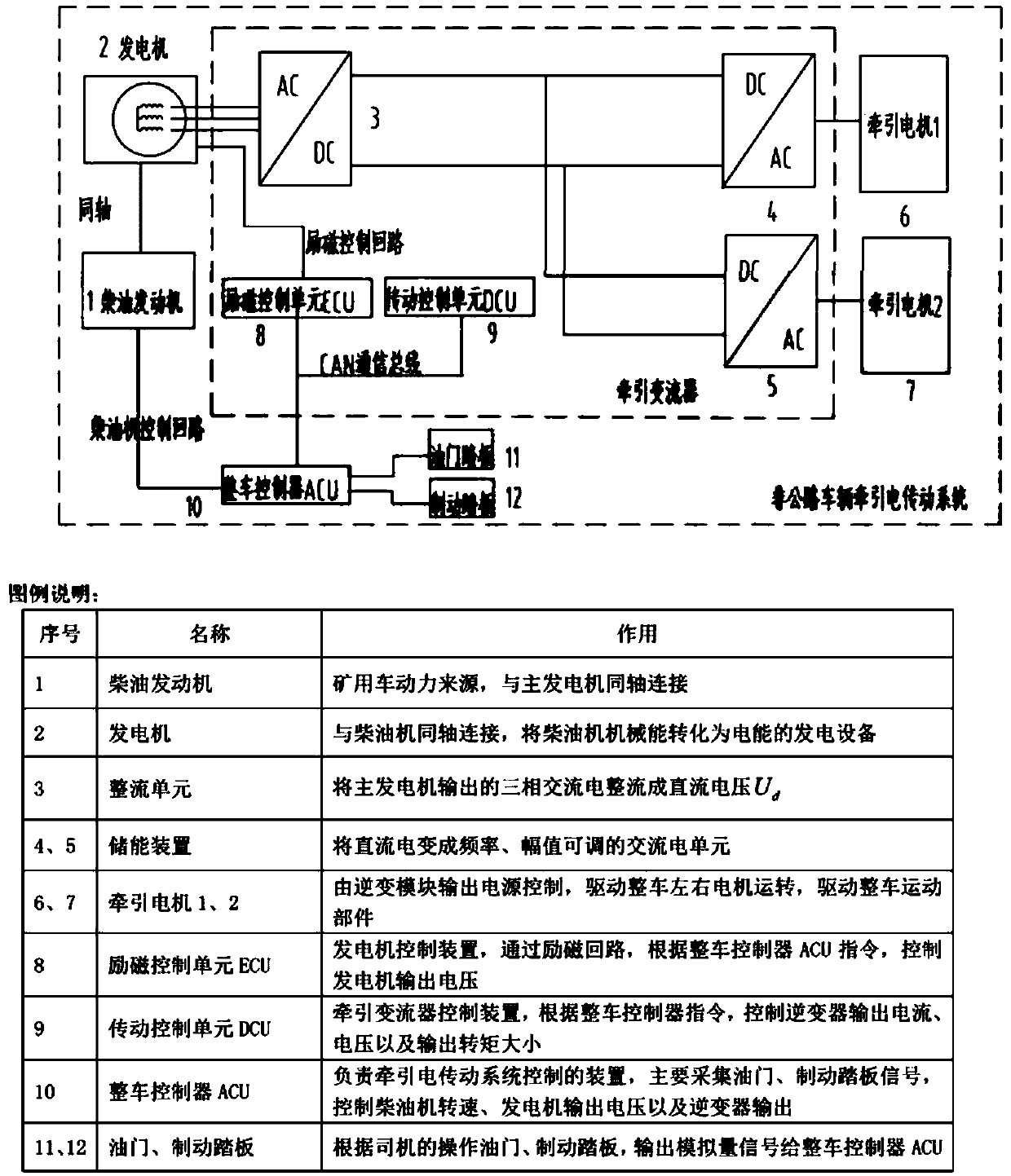

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

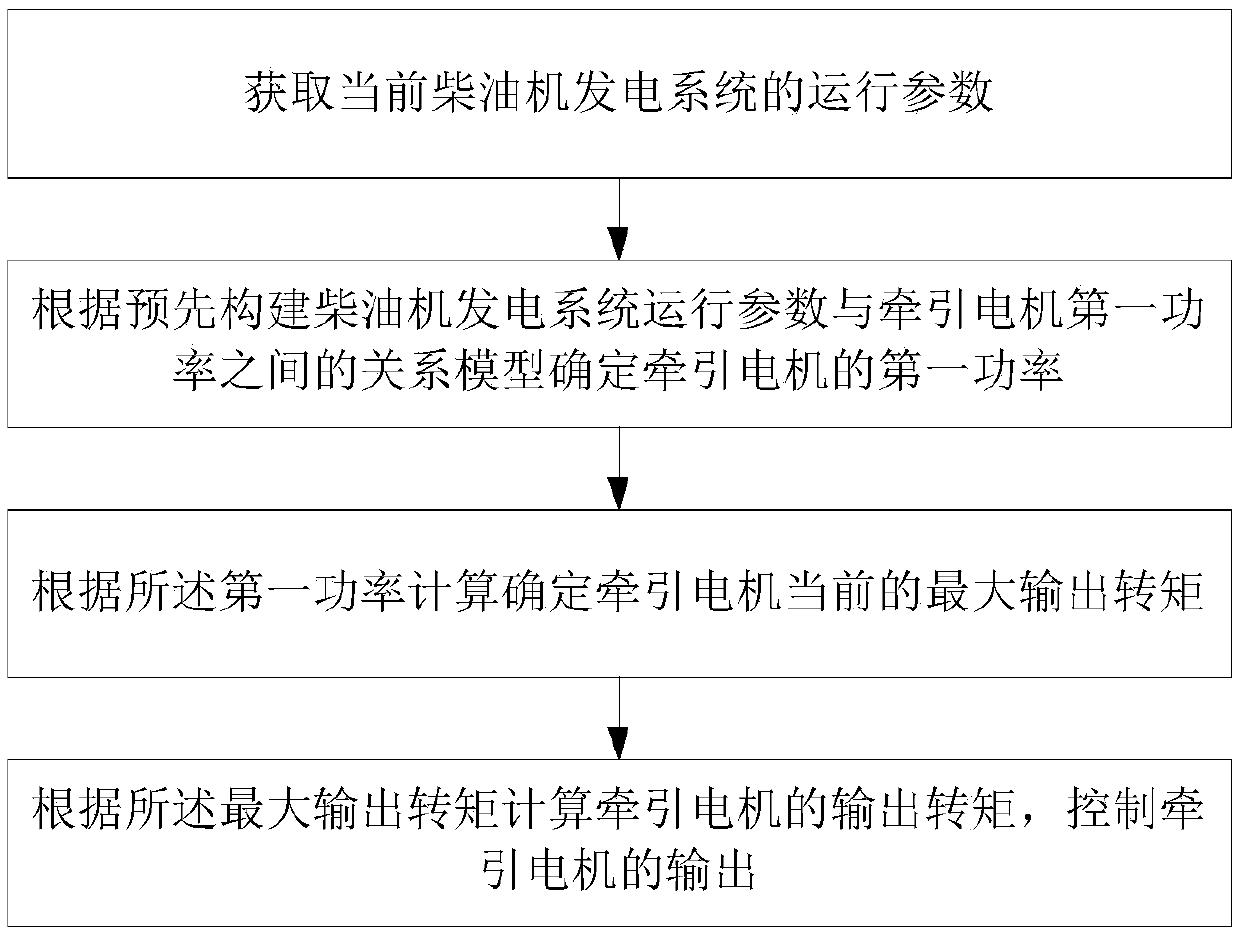

[0021] Such as figure 2 As shown, the off-highway vehicle electric transmission system control method of this embodiment obtains the current operating parameters of the diesel engine power generation system, and determines the first power of the traction motor according to the relationship model between the pre-built diesel engine power generation system operating parameters and the first power of the traction motor. Power: calculating and determining the current maximum output torque of the traction motor according to the first power, calculating the output torque of the traction motor according to the maximum output torque, and controlling the output of the traction motor. The operating parameters of the diesel generator system include the accelerator pedal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com