Soapnut saponin preparation method

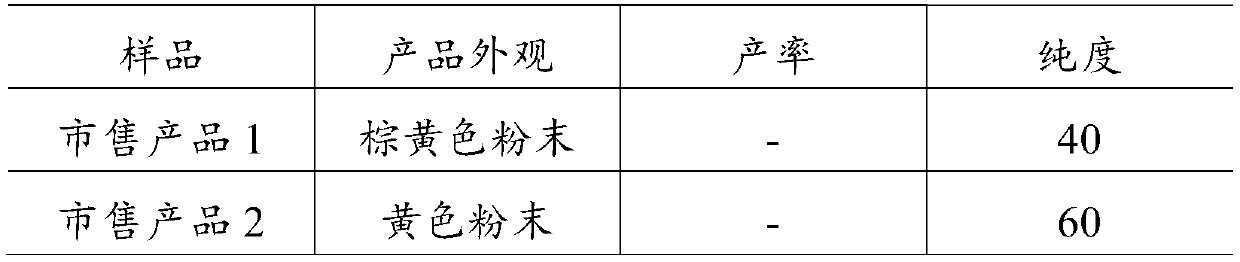

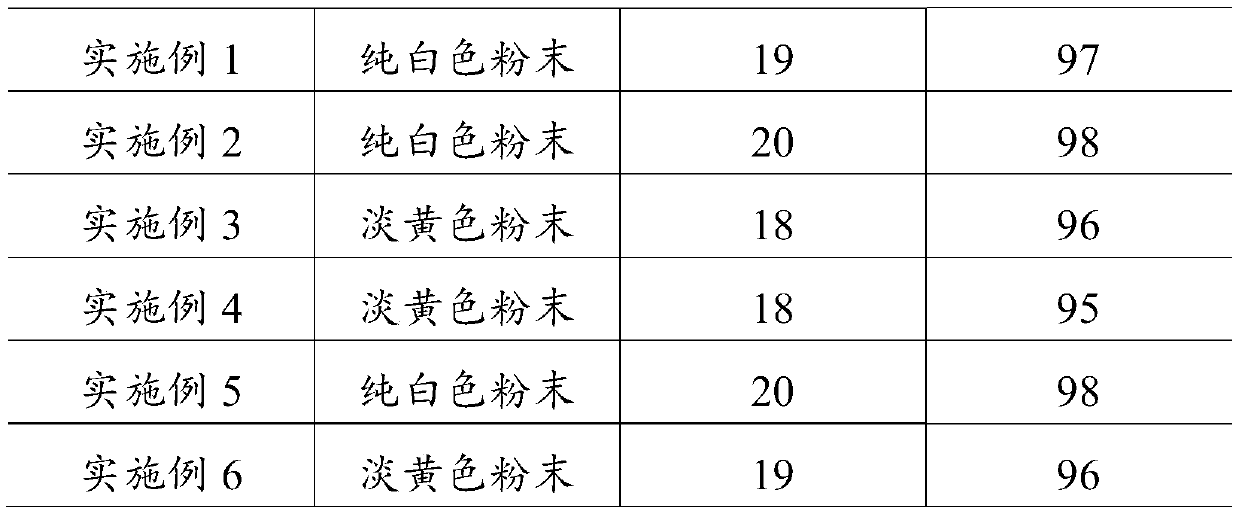

A Sapindus saponin and anion exchange column technology, applied to chemical instruments and methods, glycosides, glycosides, etc., can solve the problems of yellowish color and low purity, and achieve the effect of white color, high purity, and low toxicity of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of Sapindus saponin, comprising the steps of:

[0031] 1) Peel pretreatment: select the dried peel for vacuum drying treatment, the drying temperature is 70°C, the vacuum degree is 0.01-0.3MPa, and the moisture content of the dried peel is ≤5%;

[0032] 2) Coarse crushing of the pericarp: crush the dried pericarp to a size of 10 mesh to obtain a coarse powder of the pericarp;

[0033] 3) One-time hot water extraction: Take the coarse powder of the peel and add it to 55-65°C hot water under stirring conditions at a material-to-liquid ratio of 1:5, mix evenly at a high speed, then adjust the stirring speed to 50 rpm, and stir for 2 hours to obtain one time water extraction mixture;

[0034] 4) Primary filter press: press filter the primary water-extraction mixture within the pressure range of 0.1Mpa to get the filtrate, the filter press time is 30min, and obtain the primary filter residue and primary filtrate;

[0035] 5) Secondary hot water extract...

Embodiment 2

[0043] A preparation method of Sapindus saponin, comprising the steps of:

[0044] 1) Peel pretreatment: select dried peels for vacuum drying treatment, drying temperature is 80°C, vacuum degree is 0.01-0.3MPa, and the moisture content of dried peels is ≤5%;

[0045] 2) Coarse crushing of the pericarp: crush the dried pericarp to a size of 60 mesh to obtain a coarse powder of the pericarp;

[0046] 3) One-time hot water extraction: Take the coarse powder of the peel and add it to 58°C hot water under stirring conditions at a material-to-liquid ratio of 1:5, mix evenly at a high speed, then adjust the stirring speed to 50 rpm, and stir for 3.5 hours to obtain primary water lift the mixture;

[0047] 4) Primary filter press: filter the primary water-extraction mixture within the pressure range of 0.4Mpa to get the filtrate, the filter press time is 50min, and obtain the primary filter residue and primary filtrate;

[0048] 5) Secondary hot water extraction: Take the primary fi...

Embodiment 3

[0056] A preparation method of Sapindus saponin, comprising the steps of:

[0057] 1) Peel pretreatment: select the dried peel for vacuum drying treatment, the drying temperature is 60°C, the vacuum degree is 0.01-0.3MPa, and the moisture content of the dried peel is ≤3%;

[0058] 2) Coarse crushing of the pericarp: crush the dried pericarp to a size of 50 mesh to obtain a coarse powder of the pericarp;

[0059] 3) One-time hot water extraction: Take the coarse powder of the peel and add it to 60°C hot water under stirring conditions at a material-to-liquid ratio of 1:6, mix evenly at a high speed, then adjust the stirring speed to 40 rpm, and stir for 2.5 hours to obtain primary water lift the mixture;

[0060] 4) Primary filter press: press filter the primary water-extracted mixture within the pressure range of 0.2Mpa to get the filtrate, the filter press time is 60min, and obtain the primary filter residue and primary filtrate;

[0061] 5) Secondary hot water extraction: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com