Piercing-resistant and tear-resistant tread base rubber and preparing method thereof

A tread base, anti-tearing technology, applied to tire parts, special tires, vehicle parts, etc. heat, improve puncture and tear resistance, improve reversion resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

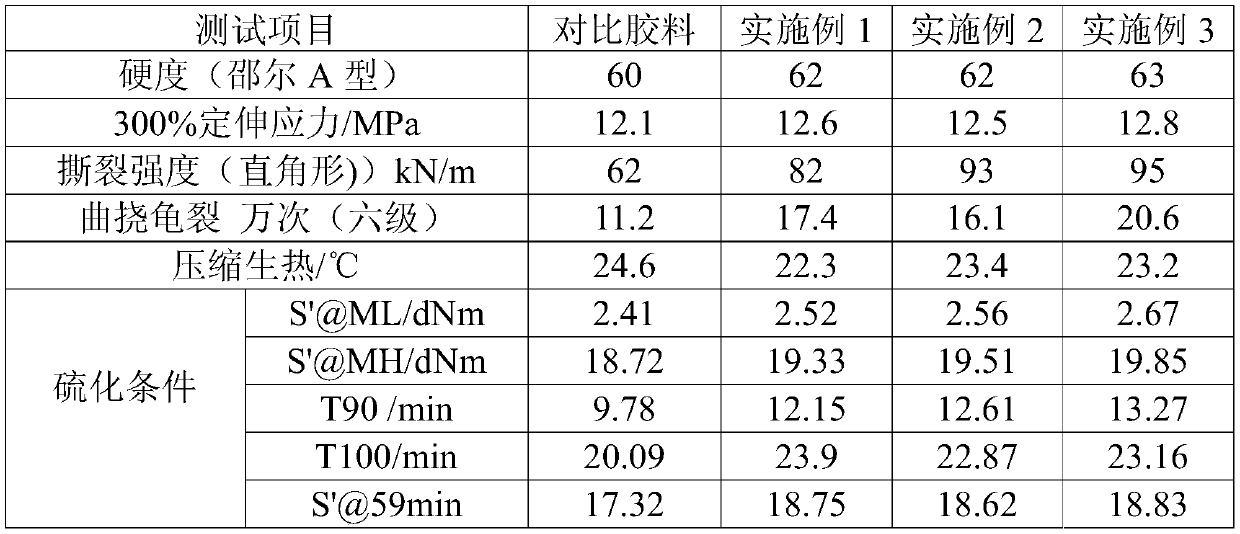

Examples

Embodiment 1

[0021] A preparation method of puncture-resistant and tear-resistant tread base rubber, comprising the following steps:

[0022] (1) One-stage mixing: in parts by weight, 100 parts of natural rubber, 28 parts of N234 carbon black, 0.1 part of graphene oxide, 10 parts of HD175MP white carbon black, 2 parts of silane coupling agent Si69, 3.5 parts of zinc oxide 2. Put 2 parts of stearic acid into BB430 type internal mixer for plasticating for 120 seconds, the pressure of the top bolt is 5.5MPa, the rotor speed is 50r / min, the temperature of glue discharge is 160℃, a section of mixed rubber is obtained, and it is parked for 8 hours ;

[0023] (2) Two-stage mixing: the parked one-stage compound rubber, 6 parts of N234 carbon black, 1.5 parts of antioxidant RD, 2 parts of antioxidant 4020, 2 parts of phenol-modified dicyclopentadiene resin, and 1 part of Type B Put the microcrystalline wax into the BB430 type internal mixer and mix for 115 seconds. The pressure of the top bolt is ...

Embodiment 2

[0026] A preparation method of puncture-resistant and tear-resistant tread base rubber, comprising the following steps:

[0027] (1) One stage mixing: 100 parts of natural rubber, 30 parts of N220 carbon black, 0.2 parts of graphene oxide, 13 parts of HD175MP white carbon black, 2 parts of silane coupling agent Si75, 3.5 parts of zinc oxide, 2 parts of stearic acid Put it into a BB430 internal mixer for plasticating for 120 seconds, the pressure of the top bolt is 5.5MPa, the rotor speed is 50r / min, and the glue discharge temperature is 160°C to obtain a section of mixed rubber, which is parked for 10 hours;

[0028] (2) Two-stage mixing: put the parked first-stage compound rubber, 5 parts of N220 carbon black, 1.5 parts of anti-aging agent RD, 1.5 parts of anti-aging agent 4020, 1 part of anti-aging agent 3100, and 3 parts of phenol-modified dicyclopentadiene Put the resin and 1.2 parts of B-type microcrystalline wax into the BB430 internal mixer for mixing, the pressure of t...

Embodiment 3

[0031] A preparation method of a puncture-resistant and tear-resistant all-steel radial tire tread base rubber, comprising the following steps:

[0032] (1) One stage mixing: 100 parts of natural rubber, 30 parts of N234 carbon black, 0.3 parts of graphene oxide, 7 parts of HD165MP white carbon black, 1 part of silane coupling agent Si69, 3.5 parts of zinc oxide, 2 parts of stearic acid Put it into a BB430 type internal mixer for plasticating for 120 seconds, the pressure of the top bolt is 5.5MPa, the rotor speed is 50r / min, and the glue discharge temperature is 160°C to obtain a section of mixed rubber, which is parked for 12 hours;

[0033] (2) Two-stage mixing: Put the parked first-stage compound rubber, 8 parts of N234 carbon black, 1 part of antioxidant RD, 2 parts of antioxidant 4020, 0.8 part of antioxidant 3100, and 3 parts of phenol-modified dicyclopentadiene Put the resin and 1 part of B-type microcrystalline wax into the BB430 type internal mixer and mix for 115 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com