Titanium-based mixed powder for laser cladding coating and manufacturing method and application

A technology of mixed powder and laser cladding, applied in coating, metal material coating process, etc., can solve the problems of limited application of titanium alloy parts, easy oxidation, poor wear resistance, etc., to improve high temperature oxidation resistance and improve hardness , the effect of extending the scope of application and foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

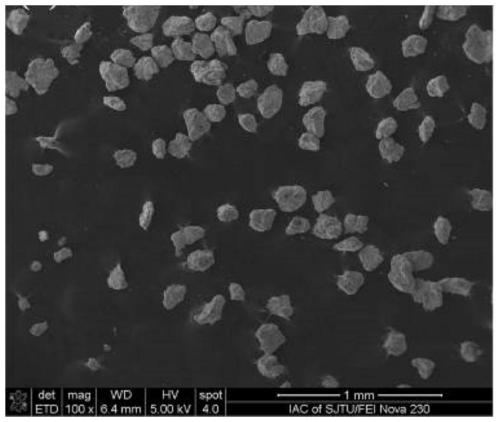

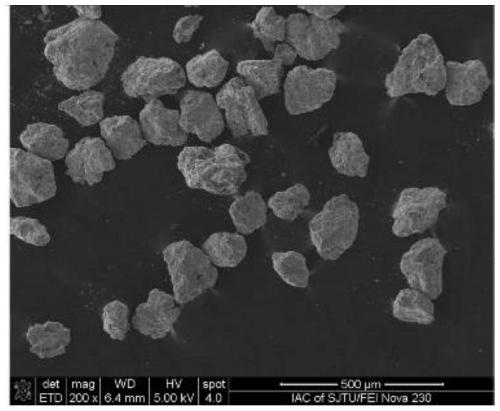

[0037] Such as figure 1 and figure 2 As shown, the titanium-based mixed powder in this example is observed under 100X and 200X. Its shape is nearly spherical, the particle size is between 75-150 μm, and its fluidity is good, which is suitable for laser cladding. Among them, the titanium-based mixed powder includes pure Ti and AlB 2 ; 2 The mass percentage of Ti is 15%-30%, and the rest is pure Ti. More preferably, the present embodiment selects AlB 2 The mass percentage is 20%.

[0038] The titanium-based mixed powder in this example is prepared by a ball milling process. Among them, the optim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com