Silicon carbide single crystal continuous growth device and growth method thereof

A technology of silicon carbide single crystal and growth device, applied in single crystal growth, single crystal growth, crystal growth and other directions, can solve the problems of low production efficiency, small crucible space, short distance, etc., to improve production efficiency, reduce costs, The effect of meeting the needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

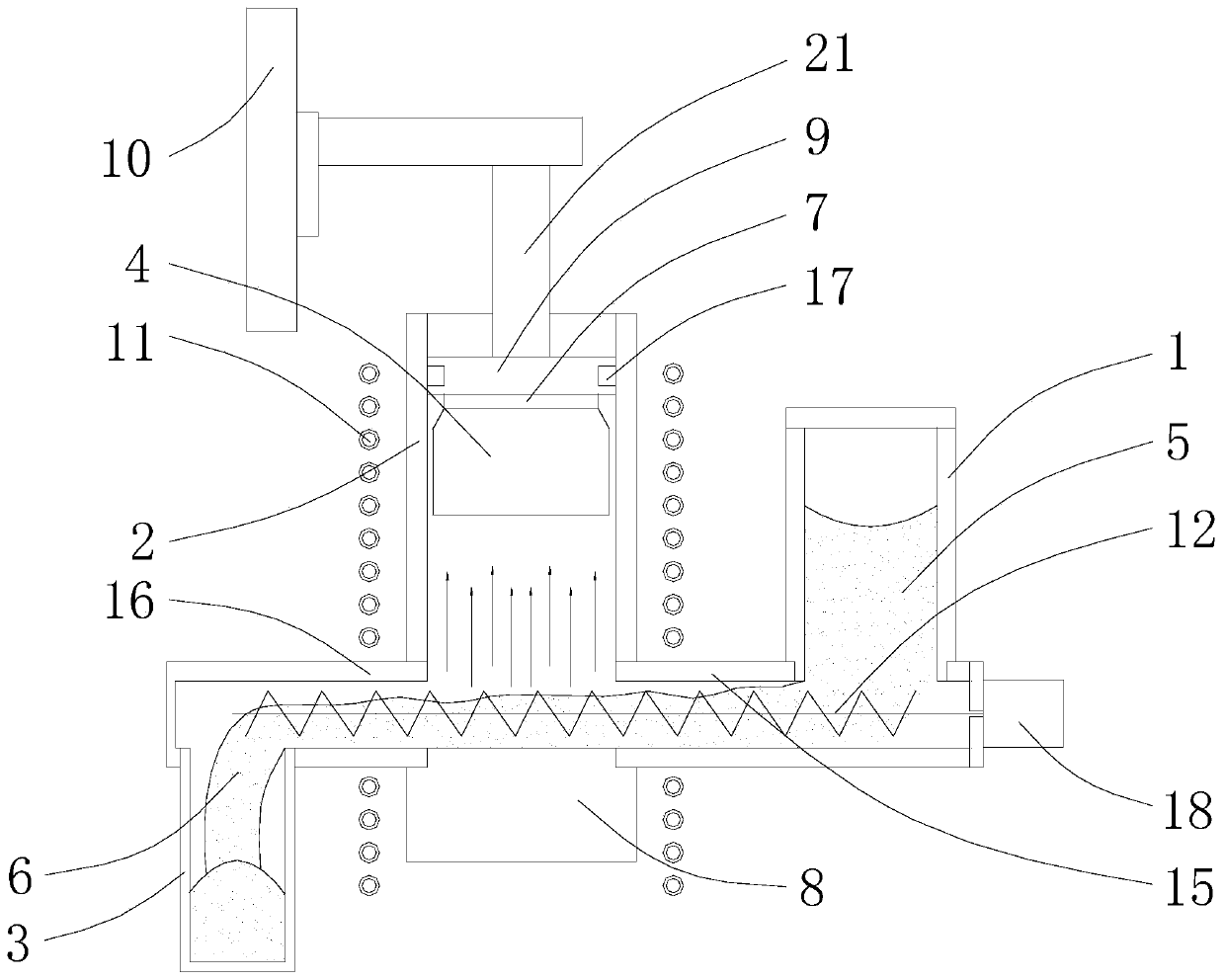

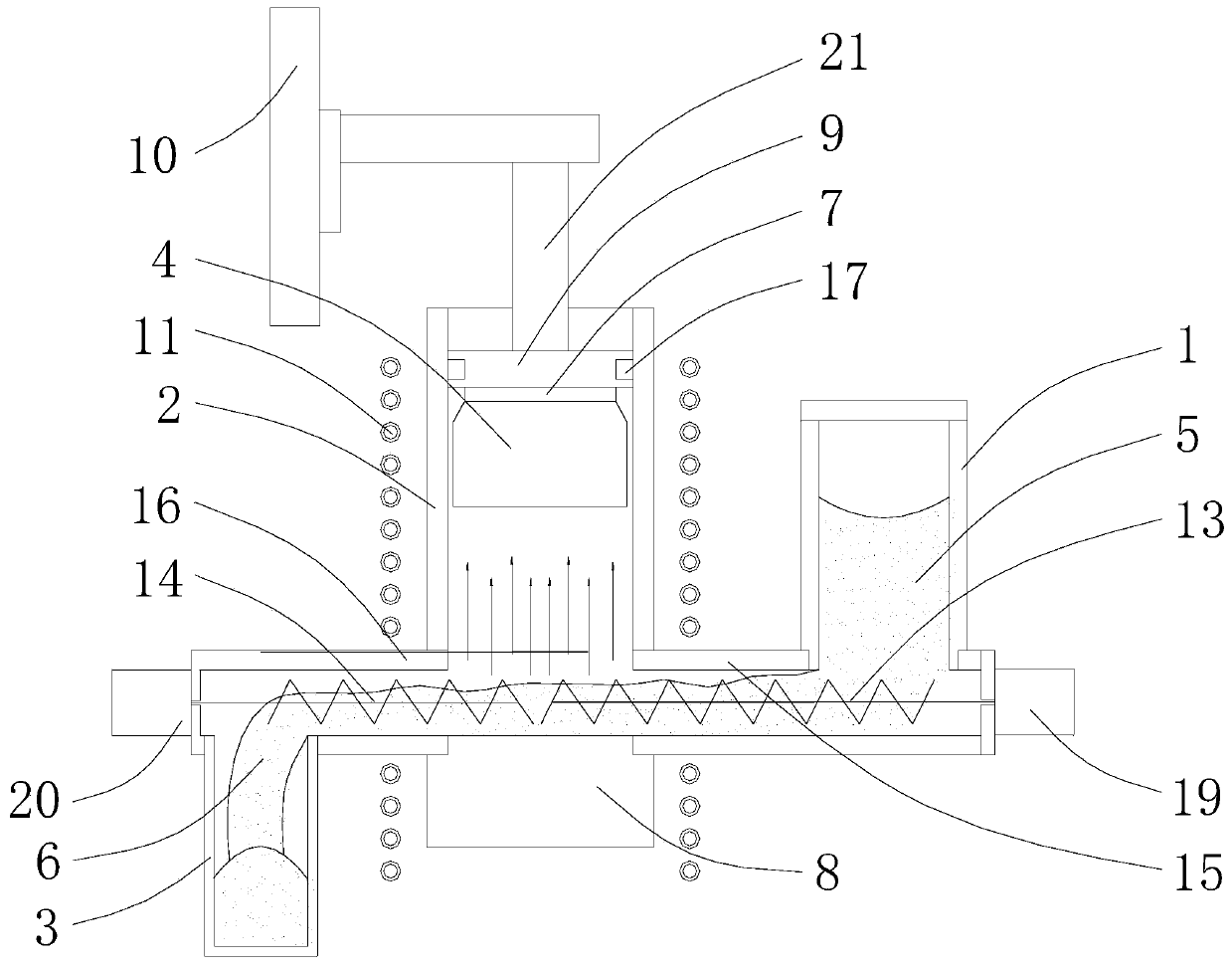

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] see Figure 1-2 As shown, the above-mentioned silicon carbide single crystal continuous growth device includes a raw material bin 1, a growth bin 2 and a recovery bin 3 connected in sequence, and is used to send the silicon carbide polycrystalline raw material 5 in the raw material bin 1 into the growth bin 2 The feeding mechanism is also used to send the residue 6 in the growth bin 2 into the recovery bin 3. The raw material bin 1, the growing bin 2, and the recovery bin 3 are connected sequentially from right to left;

[0026] The above-mentioned growth chamber 2 includes a crucible body 8, a crucible cover 9 that can be raised and lowered, sheathed or pierced on the upper part of the crucible body 8 and used to install the seed crystal 7 on its lower surface, and a driving mechanism 10 for driving the crucible cover 9 to rise and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com