Steel rail damper

A damper and rail technology, applied in the field of rail dampers, can solve problems such as inconsistent natural frequency, poor vibration and noise reduction effects, and limited vibration absorption effect, and achieve improved vibration absorption bandwidth, simple clip structure, and improved vibration absorption efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

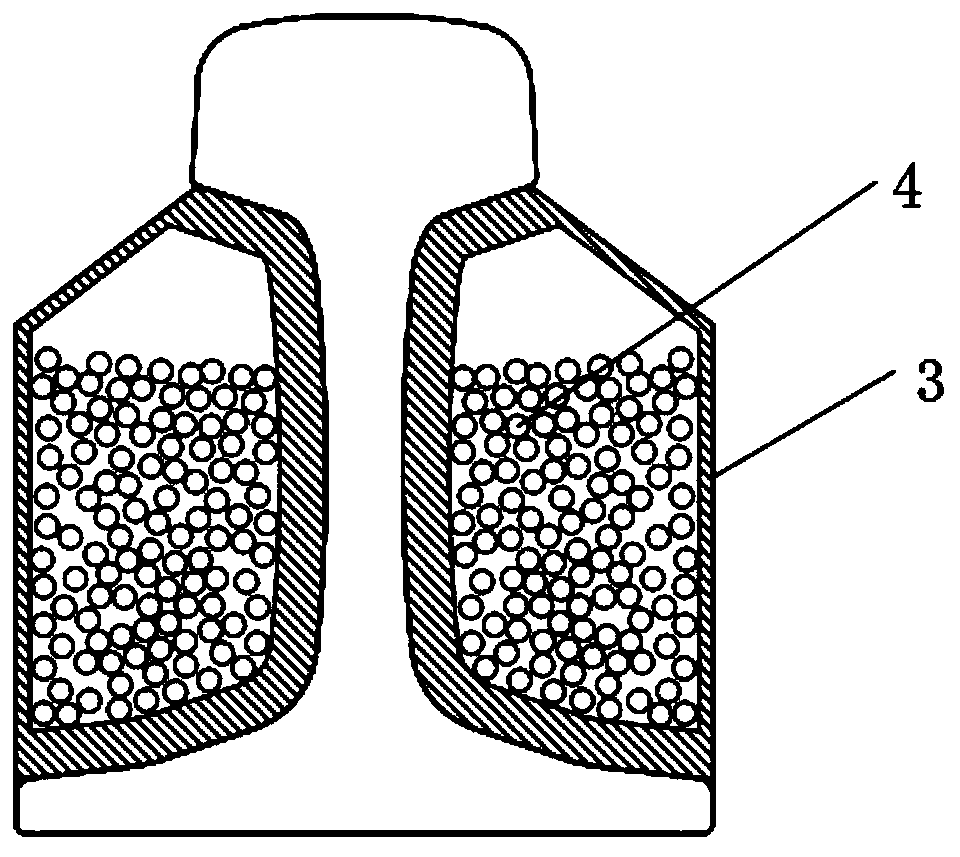

[0044] A rail damper such as figure 2 As shown, the damper 10 includes one or more cavity structures 3, the cavity structures 3 are arranged on both sides of the rail waist or above the rail bottom or below the rail bottom, and the cavity structure 2 is filled with a large number of discrete particles4.

[0045] The cavity structure 3 is arranged along the cross-sectional direction of the rail, or along the longitudinal direction of the rail.

[0046] The cavity structure 3 is set as a rigid structure, and the cavity structure 3 is in rigid contact with the rail.

[0047] The discrete particles 4 are one material or multiple materials, such as Figure 6 , the discrete particle 4 includes a first discrete particle 41 and a second discrete particle 42, the first discrete particle 41 and the second discrete particle 42 have the same or different particle sizes, that is, the discrete particle size is one or more .

[0048] The cavity structure 3 is closely attached to the rai...

Embodiment 2

[0053] This embodiment combines the principle of the traditional rail damper (the principle of the dynamic vibration absorber) of the first embodiment.

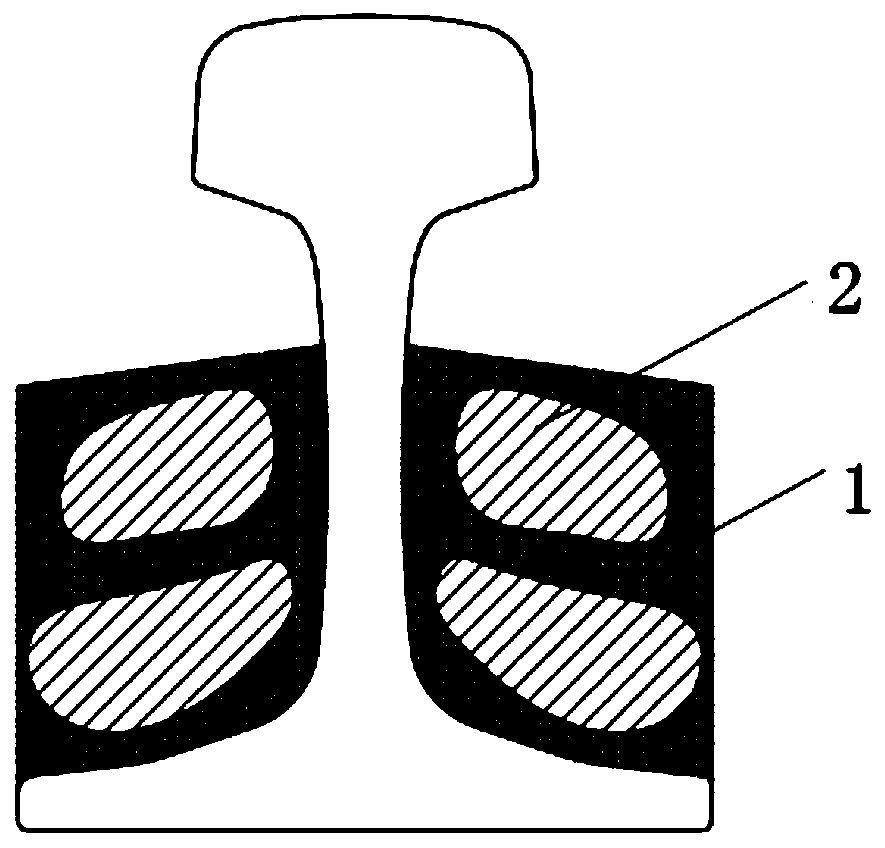

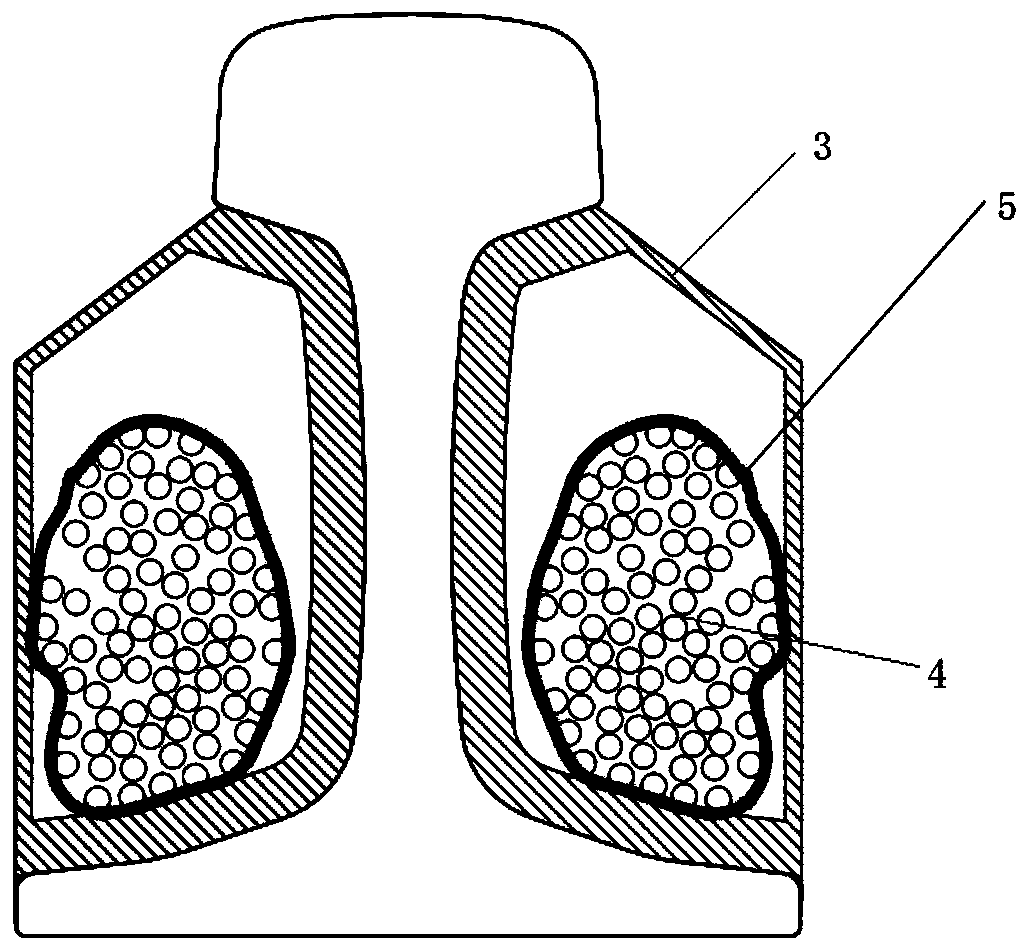

[0054] Such as Figure 4 As shown, the damper 10 in this embodiment includes an elastic damping unit 1 and a cavity structure 3 , and the cavity structure 3 is a cavity formed by the body of the elastic damping unit 1 .

[0055] Further, the cavity structure can also be a metal cavity. The elastic damping unit 1 and the cavity structure 3 are formed integrally, for example, by direct vulcanization.

[0056] Further, the cavity structure 3 is filled with discrete particles 4 .

[0057] In this embodiment, the mass unit of the traditional rail damper is changed to a structure 3 in which discrete particles fill the cavity. This structure applies the principle of a dynamic vibration absorber: the cavity structure 3 and discrete particles together constitute a mass unit, but the principle of particle damping is added on this ba...

Embodiment 3

[0059] This scheme improves on the basis of embodiment two, as Figure 5 , the cavity structure 3 is provided with an opening 6, and the opening 6 is provided with a detachable cover. The openings 6 are arranged at the top and bottom of the cavity structure 3, so that the discrete particles 4 are added from the top opening, or the discrete particles 4 are reduced from the bottom opening. The total mass and particle size of the particles in the cavity structure 3 can be adjusted through the opening 6 . When high-speed discrete particles are required, open the cover of the corresponding opening for adjustment, and after the adjustment is completed, plug the opening and put it into use. There are one or more cavity openings 6 . The cavity opening 6 can be opened or closed, for example, by adopting a threaded structure, a plug structure, an elastic clamping structure, and the like.

[0060] Such as Figure 6 , the discrete particle material, density one or more, size one or mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com