Analysis system and analysis method for methane and non-methane total hydrocarbons

A non-methane total hydrocarbon and analysis system technology, applied in the detection field of carbon-containing compounds, can solve the problems of inability to achieve continuous analysis, inability to obtain methane content, cumbersome operation and calibration processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

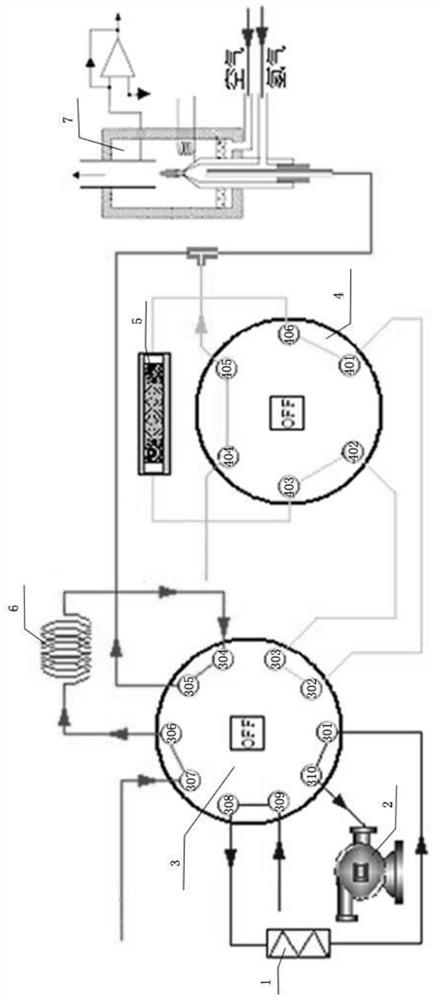

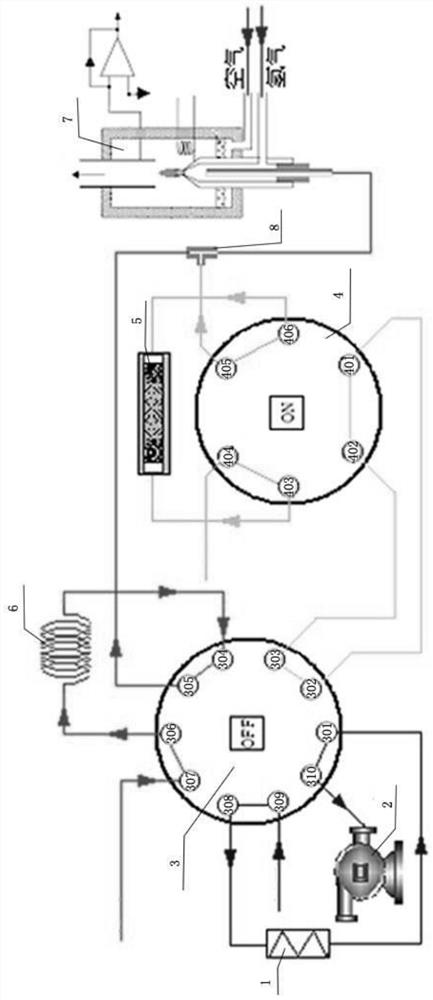

[0086] use Figure 1-3 The analysis system shown performs sample gas analysis. Among them, the low-carbon separation unit is a stainless steel column with a length of 1.5m and an inner diameter of 4mm, and the column is filled with 60-80 mesh GDX-502 polymer beads; the high-carbon adsorption unit is composed of a quartz glass tube with a length of 8cm and an inner diameter of 1.5mm, and the outer layer is wound with platinum. Heating wire, the tube is filled with 60-80 mesh graphitized carbon black Carbotrap B filler.

[0087] Analysis methods include:

[0088] 1. Sampling;

[0089] 2. For sample injection, the heating temperature for the low-carbon separation unit is 80°C;

[0090] 3. Low-carbon total hydrocarbons are backflushed, and the heating temperature for the low-carbon separation unit is 80°C;

[0091] 4. High-carbon total hydrocarbons are stored, and the heating temperature for the high-carbon adsorption unit is 240°C;

[0092] 5. High-carbon total hydrocarbons ...

Embodiment 2

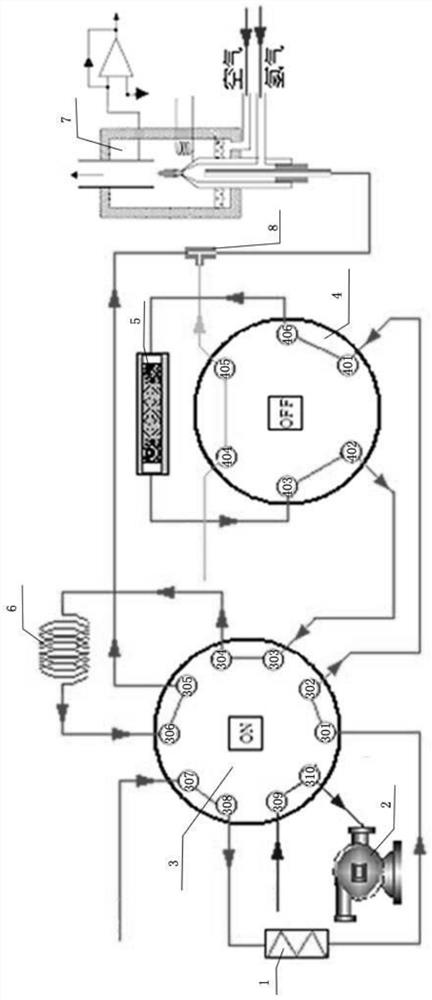

[0098] use Figure 1-3 The analysis system shown performs sample gas analysis. Among them, the low-carbon separation unit is a stainless steel column with a length of 1.5m and an inner diameter of 4mm, and the column is filled with 60-80 mesh GDX-502 polymer beads; the high-carbon adsorption unit is composed of a quartz glass tube with a length of 8cm and an inner diameter of 1.5mm, and the outer layer is wound with platinum. Heating wire, the tube is filled with 60-80 mesh graphitized carbon black Carbotrap B filler.

[0099] Analysis methods include:

[0100] 1. Sampling;

[0101] 2. For sample injection, the heating temperature for the low-carbon separation unit is 80°C;

[0102] 3. Low-carbon total hydrocarbons are backflushed, and the heating temperature for the low-carbon separation unit is 80°C;

[0103] 4. High-carbon total hydrocarbons are stored, and the heating temperature for the high-carbon adsorption unit is 240°C;

[0104] 5. High-carbon total hydrocarbons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com