High withstand voltage and low loss super junction power device

A power device and drift region technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as blocking voltage drop, and achieve the effect of low forward voltage drop and high forward blocking voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

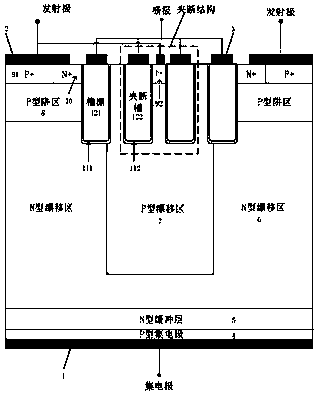

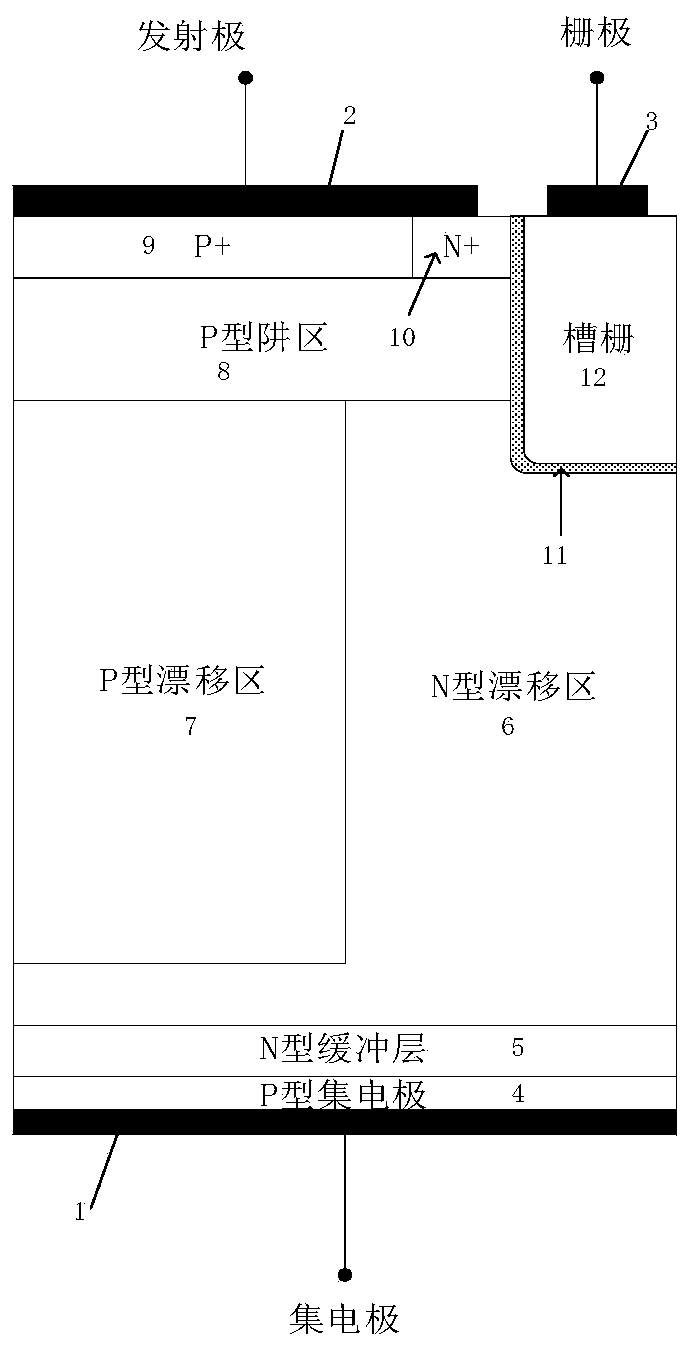

[0028] Such as image 3 A super junction insulated gate bipolar transistor is shown, including a collector structure, a drift region, an emitter structure, a trench gate structure, and a pinch-off structure, wherein the drift region is located on the collector structure, the emitter structure, and the trench gate structure And the pinch-off structure is located above the drift zone;

[0029] The collector structure includes a P-type collector layer 4 and an N-type buffer layer 5 on the upper surface of the P-type collector layer 4; the collector electrode 1 is drawn from the lower surface of the P-type collector layer 4;

[0030] The drift region includes an N-type drift region 6 and a P-type drift region 7, and the P-type drift region 7 and the N-type drift region 6 form a super junction structure or a semi-super junction structure;

[0031] The emitter structure includes a P-type well region 8 located on an N-type drift region. The upper part of the P-type well region 8 has an N-ty...

Embodiment 2

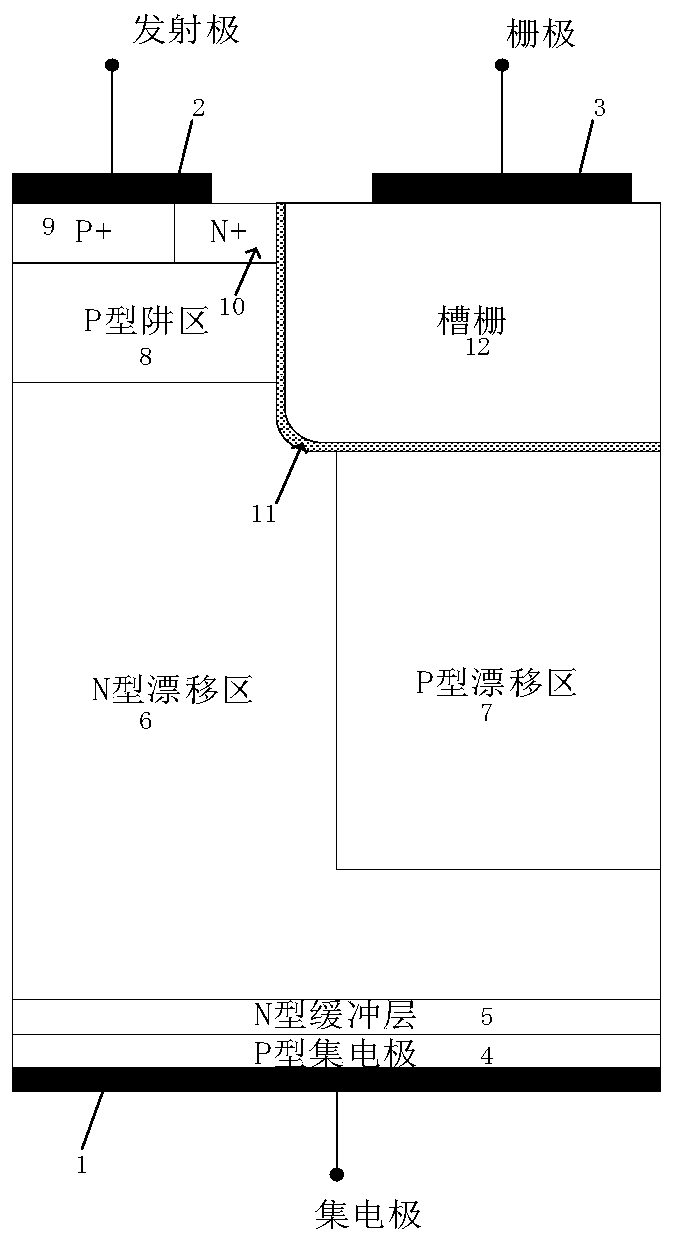

[0037] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment has a carrier storage layer 13 for blocking holes, and the carrier storage layer 13 is in contact with the lower surface of the P-type well region 8. N The upper surface of the type drift region 6 is in contact with the carrier storage layer 13; its working mechanism is the same as that of Embodiment 1. The added carrier storage layer further prevents holes from being collected by the emitter and reduces the forward conductivity. Through pressure drop.

Embodiment 3

[0039] Such as Figure 5 As shown, the difference between this example and any one of Example 1 and Example 2 is that this example has three or more pinch-off grooves side by side in the pinch-off structure and the P-type body contact area 92 between the pinch-off grooves; its working mechanism Same as in Example 1 or Example 2, the added pinch-off structure allows more holes to extract paths and lower turn-off loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com