Aramid fiber slurry and preparation method thereof, and diaphragm based on aramid fiber slurry

A slurry and aramid fiber technology, applied in the field of diaphragm based on the aramid fiber slurry, aramid fiber slurry and its preparation method, can solve the problems of difficult extraction waste liquid treatment, environmental pollution, high resource cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

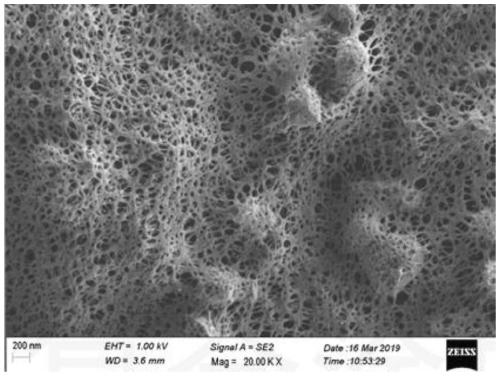

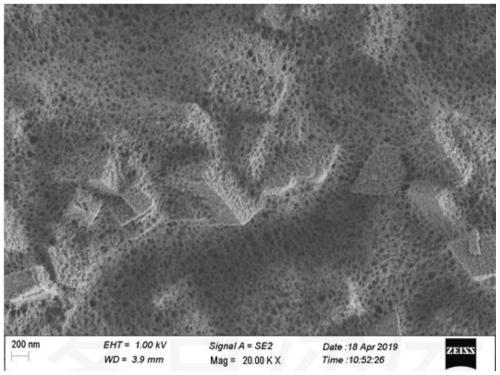

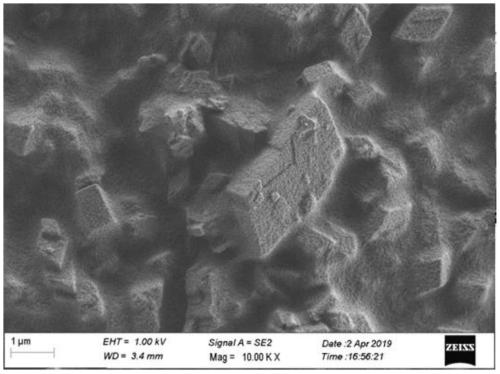

Image

Examples

Embodiment 1

[0037] A preparation method for aramid pulp, comprising the following steps:

[0038] 1) preparing the first solution and the second solution, wherein,

[0039] The preparation method of the first solution is as follows: dissolve the chloride salt in dimethylacetamide, then add meta-aramid fibers to obtain the first base material, seal the first base material in the stirring tank, and insert it into the clamp of the stirring tank Put hot water at 80°C into the sleeve, and stir at 80°C for 10 hours to dissolve the meta-aramid fiber in dimethylacetamide to obtain the first solution, wherein the stirring speed is 35r / min, calculated by mass fraction , chlorine salt is 2wt% of the first base material, dimethylacetamide is 78wt% of the first base material, meta-aramid fiber is 20wt% of the first base material, and chloride salt is lithium chloride;

[0040] The preparation method of the second solution is as follows: put the alumina and tripropylene glycol into the mixing tank aft...

Embodiment 2

[0043] A preparation method for aramid pulp, comprising the following steps:

[0044] 1) preparing the first solution and the second solution, wherein,

[0045] The preparation method of the first solution is as follows: dissolve the chloride salt in dimethylacetamide, then add meta-aramid fibers to obtain the first base material, seal the first base material in the stirring tank, and insert it into the clamp of the stirring tank Put hot water at 80°C into the sleeve, and stir at 80°C for 10 hours to dissolve the meta-aramid fibers in dimethylacetamide to obtain the first solution, wherein the stirring speed is 35r / min, calculated by mass fraction , chlorine salt is 8wt% of the first base material, dimethylacetamide is 72wt% of the first base material, meta-aramid fiber is 20wt% of the first base material, and chloride salt is lithium chloride;

[0046] The preparation method of the second solution is as follows: put the alumina and tripropylene glycol into the mixing tank af...

Embodiment 3

[0049] A preparation method for aramid pulp, comprising the following steps:

[0050] 1) preparing the first solution and the second solution, wherein,

[0051]The preparation method of the first solution is as follows: dissolve the chloride salt in dimethylacetamide, then add meta-aramid fibers to obtain the first base material, seal the first base material in the stirring tank, and insert it into the clamp of the stirring tank Put hot water at 80°C into the sleeve, and stir at 80°C for 10 hours to dissolve the meta-aramid fiber in dimethylacetamide to obtain the first solution, wherein the stirring speed is 35r / min, calculated by mass fraction , chlorine salt is 3wt% of the first base material, dimethylacetamide is 75wt% of the first base material, meta-aramid fiber is 22wt% of the first base material, and chloride salt is lithium chloride;

[0052] The preparation method of the second solution is as follows: put the alumina and tripropylene glycol into the mixing tank afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com