Core-shell structure ceramsite based on iron tailings and alkali slag and its preparation method

A technology of core-shell structure and iron tailings powder, which is applied in the production of clay products, other household utensils, ceramic materials, etc., can solve the problems of environmental damage, destruction of natural mountain landscape and green vegetation, water and soil erosion, etc., to reduce cracking, Suitable for large-scale industrial promotion and the effect of reducing liquid phase viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

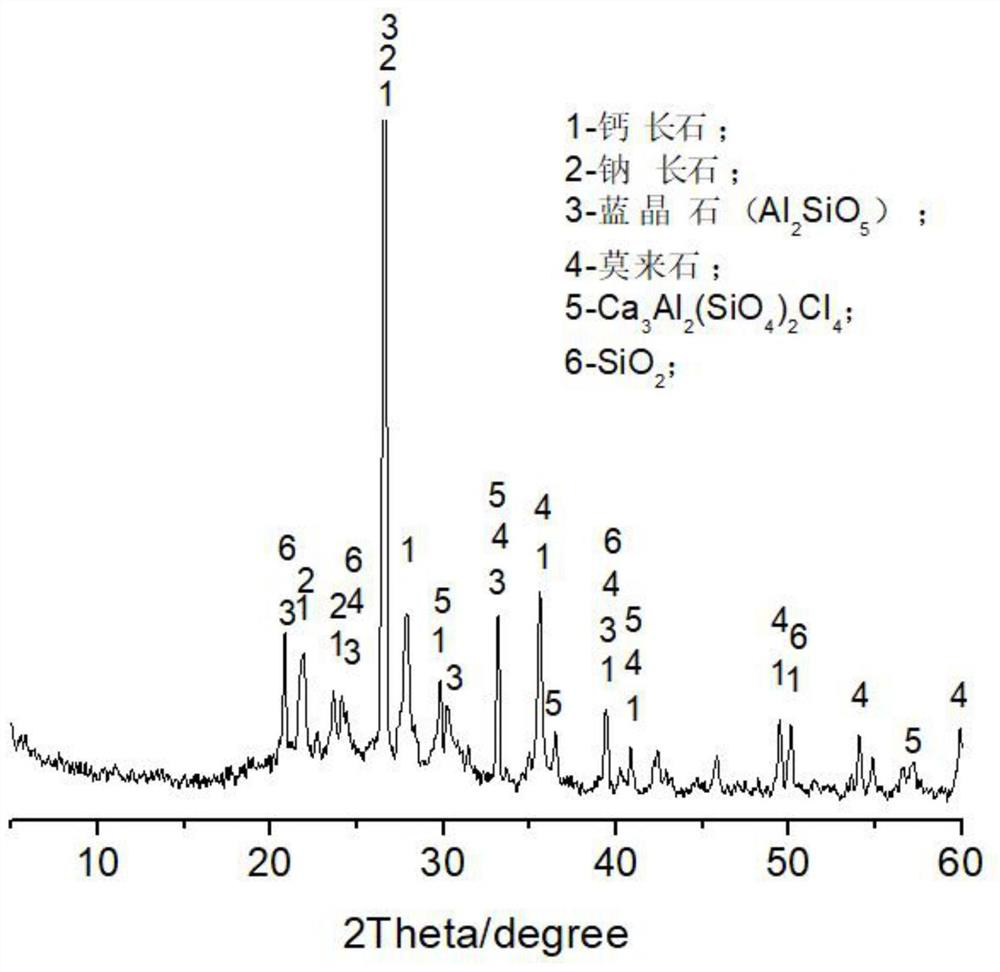

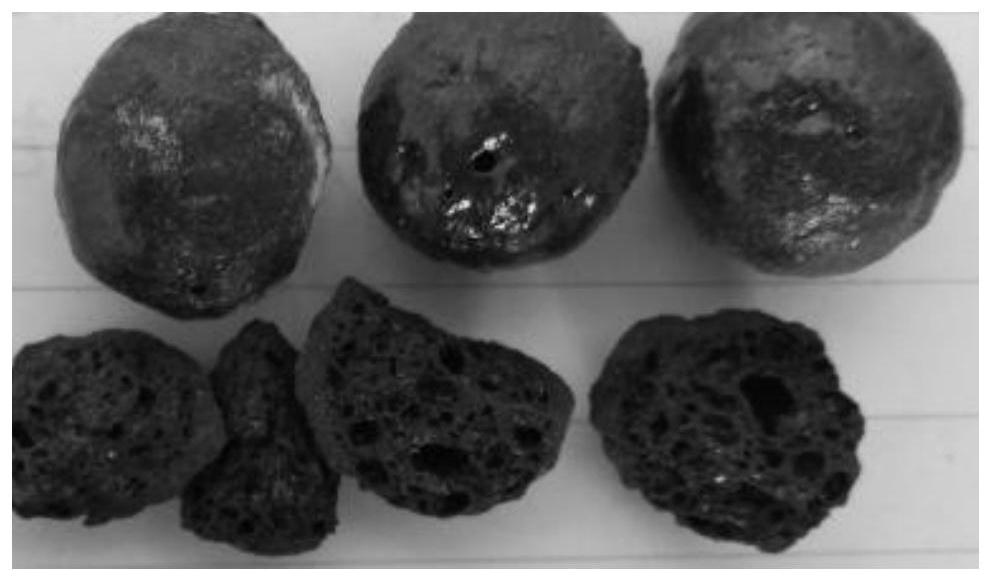

Image

Examples

Embodiment 1

[0031] A preparation method of core-shell structure ceramsite based on iron tailings and alkali slag, comprising the following steps:

[0032] 1) Preparation of core raw material pellets: Weigh iron tailings powder, fly ash and alkali slag according to the proportion and mix them evenly to obtain core batch material A. Put core batch material A into the ball forming machine and add water until The water-solid ratio is 0.2, and granulated to obtain core raw meal balls with a particle size of 5mm, wherein the water contains 0.5wt% of the water quality of the water reducing agent, and the iron tailings powder is 70% by mass percentage, and the pulverized coal powder is 70%. Ash is 26%, alkali slag is 4%;

[0033] Preparation of shell batch material B: Weigh iron tailings powder, fly ash and flux in proportion and mix uniformly to obtain shell layer batch material B, wherein, in terms of mass percentage, iron tailings powder is 74%, powder The coal ash is 25%, the flux is 1%, and...

Embodiment 2

[0038] A preparation method of core-shell structure ceramsite based on iron tailings and alkali slag, comprising the following steps:

[0039] 1) Preparation of core raw material pellets: Weigh iron tailings powder, fly ash and alkali slag according to the proportion and mix them evenly to obtain core batch material A. Put core batch material A into the ball forming machine and add water until The water-solid ratio is 0.3, and granulated to obtain core raw meal balls with a particle size of 7mm, wherein the water contains 0.3wt% of the water quality of the water reducing agent, and the iron tailings powder is 70% by mass percentage, and the pulverized coal powder is 70%. Ash is 24%, alkali slag is 6%;

[0040] Preparation of shell batch B: Weigh iron tailings powder, fly ash and flux in proportion and mix them uniformly to obtain shell batch B, wherein, in terms of mass percentage, iron tailings powder is 73%, powder The coal ash is 24%, the flux is 3%, and the flux is gypsum...

Embodiment 3

[0045] A preparation method of core-shell structure ceramsite based on iron tailings and alkali slag, comprising the following steps:

[0046] 1) Preparation of core raw material pellets: Weigh iron tailings powder, fly ash and alkali slag according to the proportion and mix them evenly to obtain core batch material A. Put core batch material A into the ball forming machine and add water until The water-solid ratio is 0.3, and granulated to obtain core raw meal balls with a particle size of 10mm, wherein the water contains 0.2wt% of the water quality of the water reducing agent, and the iron tailings powder is 68% in terms of mass percentage, and the pulverized coal is 68%. Ash is 24%, alkali slag is 8%;

[0047] Preparation of shell batch material B: Weigh iron tailings powder, fly ash and flux in proportion and mix uniformly to obtain shell layer batch material B, wherein, in terms of mass percentage, iron tailings powder is 72%, powder The coal ash is 23%, the flux is 5%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com