Preparation method of air purification activated carbon adsorption material

An activated carbon adsorption and air purification technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of poor molding, poor air purification effect, and poor adsorption effect of small molecule organic matter, etc., to achieve small collapse , good activity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

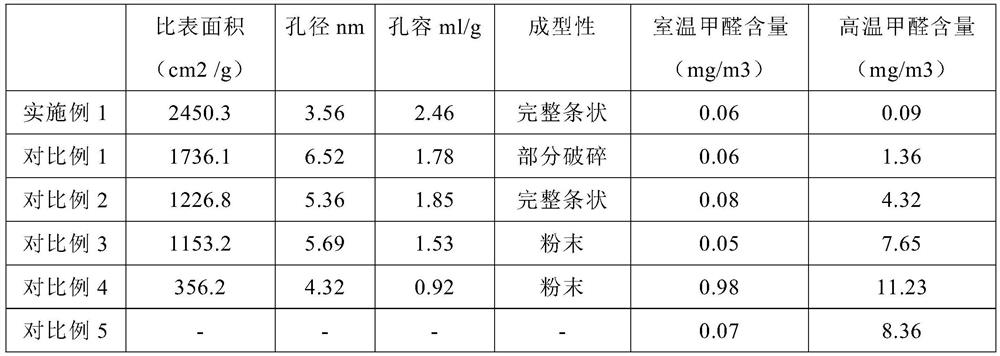

Examples

Embodiment 1

[0018] A method for preparing an air-purifying activated carbon adsorption material, comprising: uniformly mixing sorghum flour and zinc chloride, adding to cold water, beating uniformly, heating to 95 degrees under stirring, adding sodium hydroxide, and keeping the temperature open 3 hours, stop stirring, heat to 155 degrees, keep warm for 3 hours, after solidification, cool, cut the solidified material into the same size, put it in a high-temperature furnace, and calcine it in a nitrogen atmosphere. After calcination, put the material Put it into 10% hydrochloric acid water, heat to 60°C, shake and wash slowly, then rinse with water until neutral drying.

[0019] The mass ratio of sorghum flour, zinc chloride and water is 1:1:3. The molar ratio of zinc chloride to sodium hydroxide is 1:1. The preparation method of the air-purifying activated carbon adsorption material is characterized in that the solidified material is cut into strips of 5 cm×1 cm×1 cm in the same size. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com