Preparation method of highly air-permeable vinylidene fluoride polymer mixed-coated separator

A technology of vinylidene fluoride and vinylidene fluoride, which is applied to the preparation of high-permeability vinylidene fluoride polymer mixed-coated separators, lithium batteries, and high-permeability vinylidene fluoride polymer mixed-coated separators, which can solve the unfavorable lithium Lithium ion conduction and cycle performance of the battery, diaphragm pore plugging and air permeability, and insignificant effect, etc., to achieve the effect of improving coating production efficiency, increasing liquid retention, and increasing pore-forming uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Mix 7 parts of PVDF with 100 parts of DMAC, stir and dissolve at 50°C and 1500rpm for 3h, then add 20 parts of alumina, mix and stir for 1h, finally add 10 parts of polyglycerol, stir at 500rpm for 0.5h to obtain a mixed slurry ;

[0067] (2) Coat the mixed slurry on both sides of a 7 μm polyethylene-based film, and then pass through a pore-forming pool containing 0.3% polyoxyethylene alkylamine and 5% DMAC. The temperature of the pore-forming pool is 50°C, and the pore-forming time is 10s. ; Then enter the extraction tank with a temperature of 50°C and a pH of 8, and the extraction time is 30s;

[0068] (3) After pore-making and extraction, the separators were dried in three-section ovens at temperatures of 45, 55, and 50°C in sequence, and rolled to obtain mixed-coated separators with a single-side coating thickness of 3 μm.

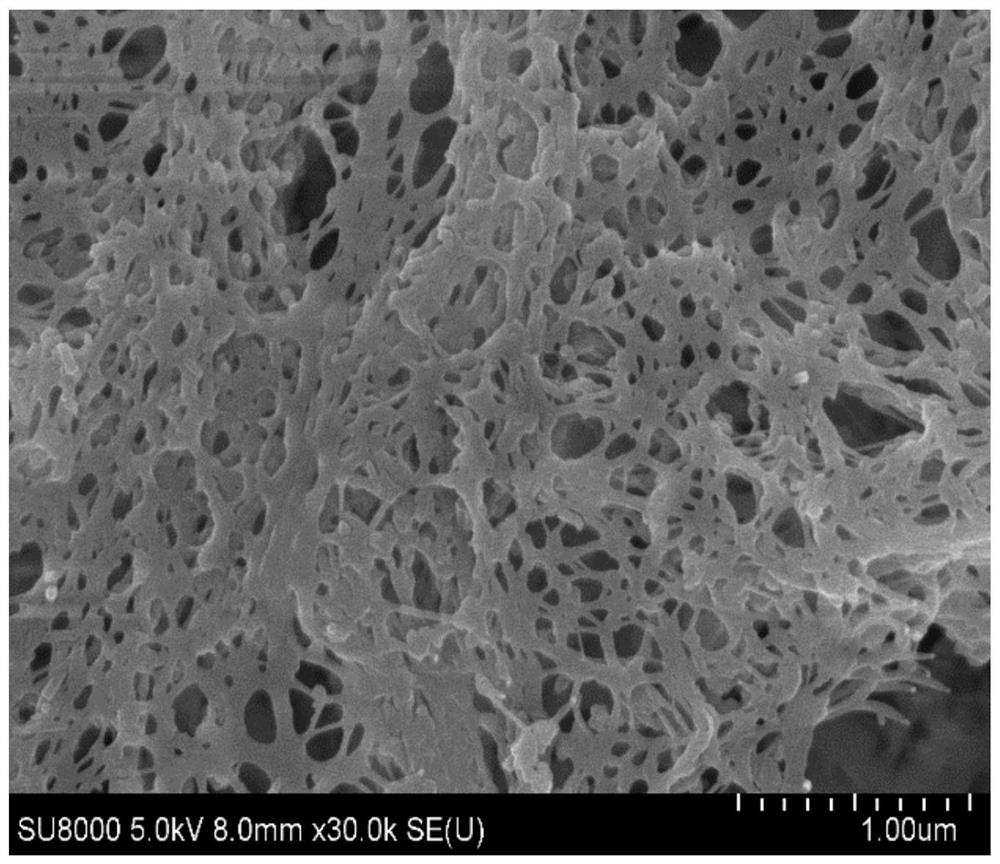

[0069] The SEM topography of the final mixed-coated separator surface is as follows figure 1 shown.

[0070] Depend on figure 1 It can be...

Embodiment 2

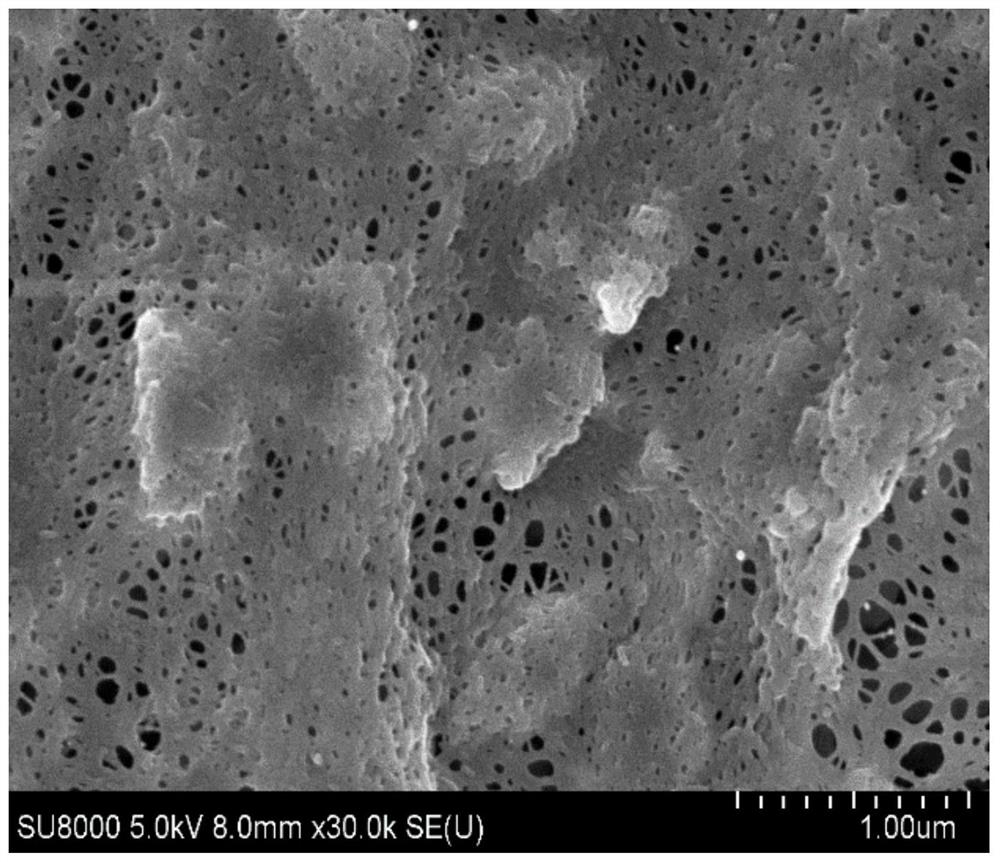

[0072] (1) Mix 7 parts of PVDF with 100 parts of NMP, stir and dissolve at 50°C and 1500rpm for 3h, then add 20 parts of alumina, mix and stir for 1.5h, finally add 15 parts of polyglycerol, stir at 500rpm for 0.5h to obtain a mixed slurry material;

[0073] (2) Coat the mixed slurry on both sides of a 7 μm polyethylene-based film, and then pass through a pore-forming pool containing 0.3% polyoxyethylene alkylamine and 5% NMP. The temperature of the pore-forming pool is 50°C, and the pore-forming time is 15s ; Then enter the extraction tank with a temperature of 50°C and a pH of 8, and the extraction time is 1 min;

[0074] (3) After pore-making and extraction, the separators were dried in three-section ovens at temperatures of 45, 55, and 50°C in sequence, and rolled to obtain mixed-coated separators with a single-side coating thickness of 3 μm.

Embodiment 3

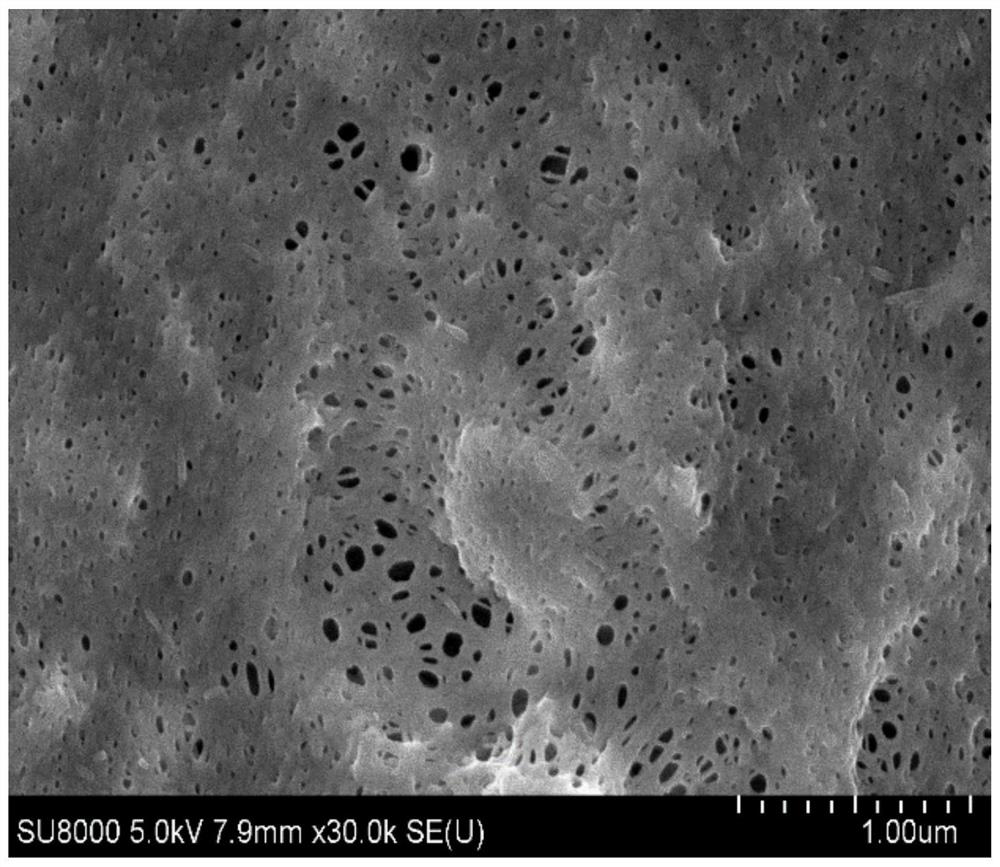

[0076] (1) Mix 9 parts of PVDF with 100 parts of DMAC, stir and dissolve at 40°C and 1500rpm for 4h, then add 25 parts of alumina, mix and stir for 2h, finally add 10 parts of polyglycerol, stir at 500rpm for 0.5h to obtain a mixed slurry ;

[0077] (2) Coat the mixed slurry on both sides of a 7 μm polyethylene-based film, and then pass through a pore-forming pool containing 0.3% polyoxyethylene alkylamine and 5% DMAC. The temperature of the pore-forming pool is 50°C, and the pore-forming time is 20s. ; Then enter the extraction tank with a temperature of 50°C and a pH of 8, and the extraction time is 1 min;

[0078] 3. After pore-making and extraction, the diaphragm is sequentially dried in three-section ovens with temperatures of 45, 55, and 50°C, and rolled to obtain a mixed-coated diaphragm with a single-sided coating thickness of 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com