Oriented multi-channel carbonized wood interlayer and preparation method and application thereof

A carbonized wood and multi-channel technology, applied in electrical components, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of easy dissolution of polysulfides and low stability of Li-S batteries, so as to improve electrochemical performance and cycle Stable, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dry-clean the birch, dry it, and cut it by adjusting the different angles of the small desktop electric saw to obtain different orientations, that is, the direction of the micropore channel in the birch and the cutting direction are respectively 0°, 30°, 45°, and 60° °, 90° wooden strip, its length, width, thickness are 5cm, 3cm, 1mm respectively.

[0042] (2) Take 9g of NaOH and 4g of Na 2 SO 3Dissolve in 100ml deionized water, NaOH and Na in the resulting mixture 2 SO 3 Concentrations are 9wt% and 4wt%, respectively. The above-mentioned birch strips are immersed in 100ml of the mixed solution, and transferred to a hydrothermal reaction kettle, and reacted at 110° C. for 12 hours. After washing and drying, lignin-free birch strips are obtained.

[0043] (3) get above-mentioned orientation angle respectively and be 0 °, 30 °, 45 °, 60 °, 90 ° birch bar without lignin, its length, width, thickness are respectively 5cm, 3cm, 1mm, each 4 pieces in crucible, Place i...

Embodiment 2

[0046] According to embodiment 1, get the NaOH of 10g and the NaOH of 5g 2 SO 3 Dissolve in 100ml deionized water, NaOH and Na in the resulting mixture 2 SO 3 Concentrations are 10wt% and 5wt%, hydrothermal reaction at 115°C for 11h, pre-oxidation holding time for 5h, carbonization is heating up to 1000°C, holding time for 5h, the rest are the same as in Example 1, cut into a side length of 10.7mm, thickness 1mm square carbonized wood compartment.

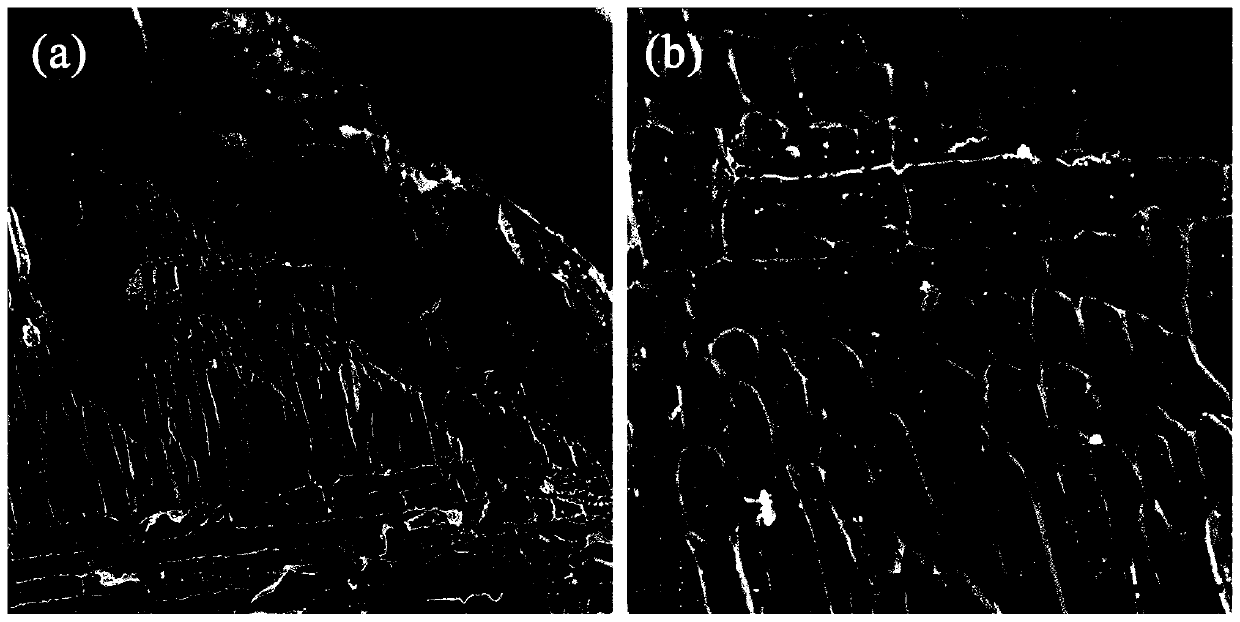

[0047] Present embodiment orientation is the FE-SEM photo of 45 ° carbonized wood interlayer section, as figure 1 As shown, it can be seen that the interlayer has a continuous multi-channel pore structure, and the channels form an angle of about 45° with the C-axis.

Embodiment 3

[0049] According to embodiment 1, get the NaOH of 11g and the NaOH of 6g 2 SO 3 Dissolve in 100ml deionized water, NaOH and Na in the resulting mixture 2 SO 3 Concentrations are 11wt% and 6wt%, hydrothermal reaction at 120°C for 10h, pre-oxidation holding time for 6h, carbonization is heating up to 1100°C, holding for 4h, the rest are the same as in Example 1, cut into a side length of 10.7mm, thickness 1mm square carbonized wood compartment.

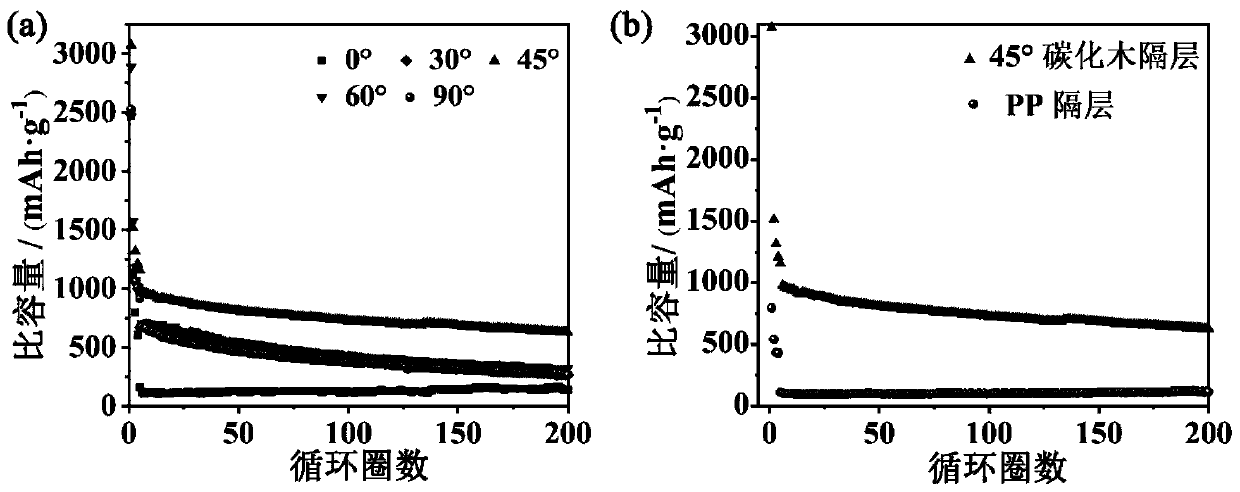

[0050] The carbonized wood separator with different orientations obtained in this example and the commercial polypropylene (PP) separator are simply laminated and compounded as a lithium-sulfur battery composite separator, and the activated carbon and sublimated sulfur are crushed and mixed at a mass ratio of 1:6. , heated at 155°C for 10h, and naturally cooled to obtain a carbon-sulfur (C / S) composite material. Mix the C / S composite material, acetylene black, and polyvinylidene fluoride (PVDF) in a mass ratio of 7:2:1 Then uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com