Anti-deformation reinforcing system for inflatable core mold and installation construction method thereof

A technology of anti-deformation and installation cavity, which is applied in the direction of molds, manufacturing tools, ceramic molding cores, etc., can solve the problems of long construction period, high cost of prefabricated formwork or steel mold trolley, complicated installation, reinforcement and disassembly, etc., so as to improve the service life , to reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

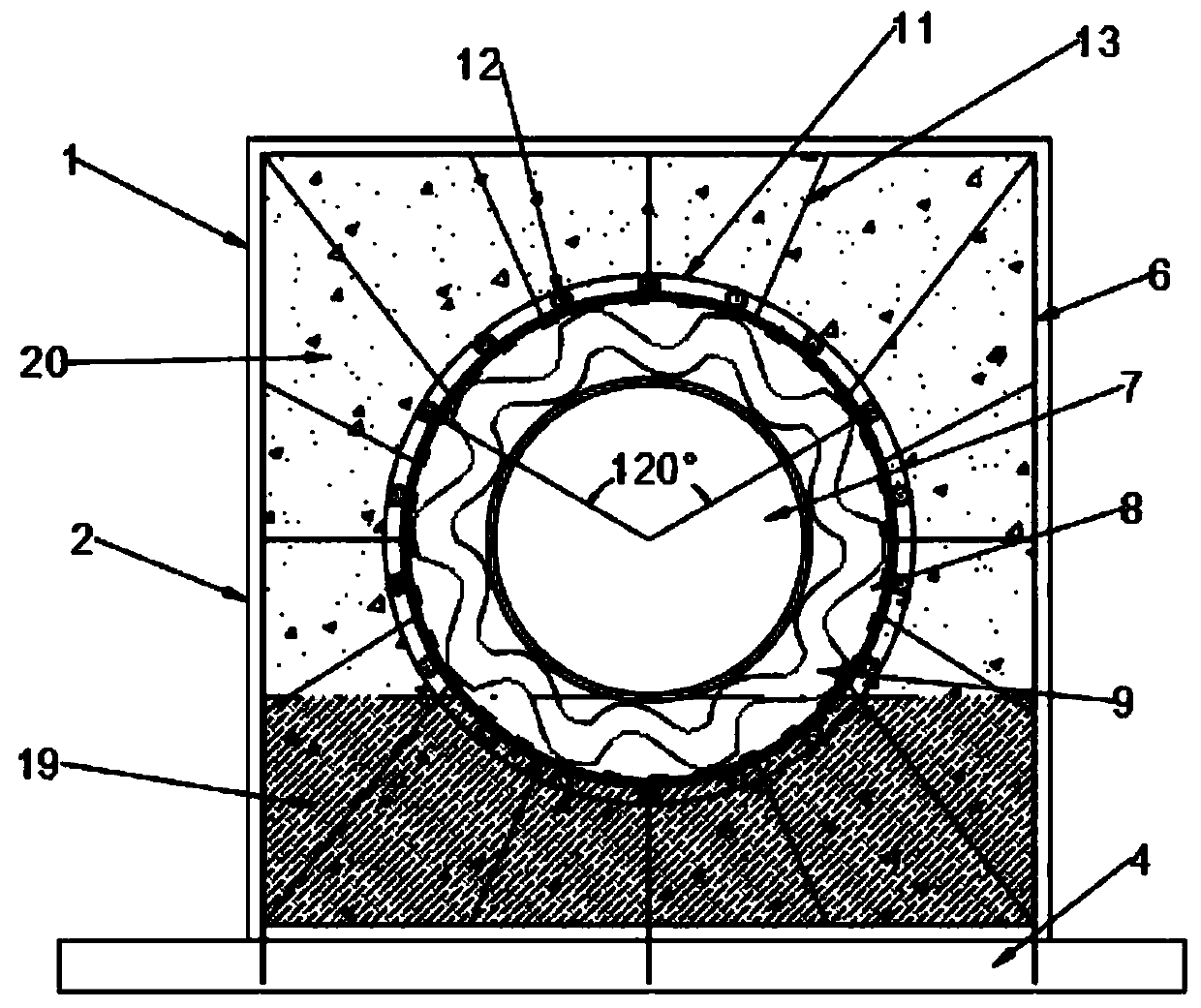

[0034] The invention proposes an anti-deformation reinforcement system for an inflatable mandrel. The anti-deformation reinforcement system includes an outer mold device, an inner mold mechanism sleeved inside the outer mold device, and a positioning reinforcement set between the outer mold device and the inner mold mechanism. device; a pouring chamber in a U-shaped structure is formed between the outer mold device and the inner mold mechanism;

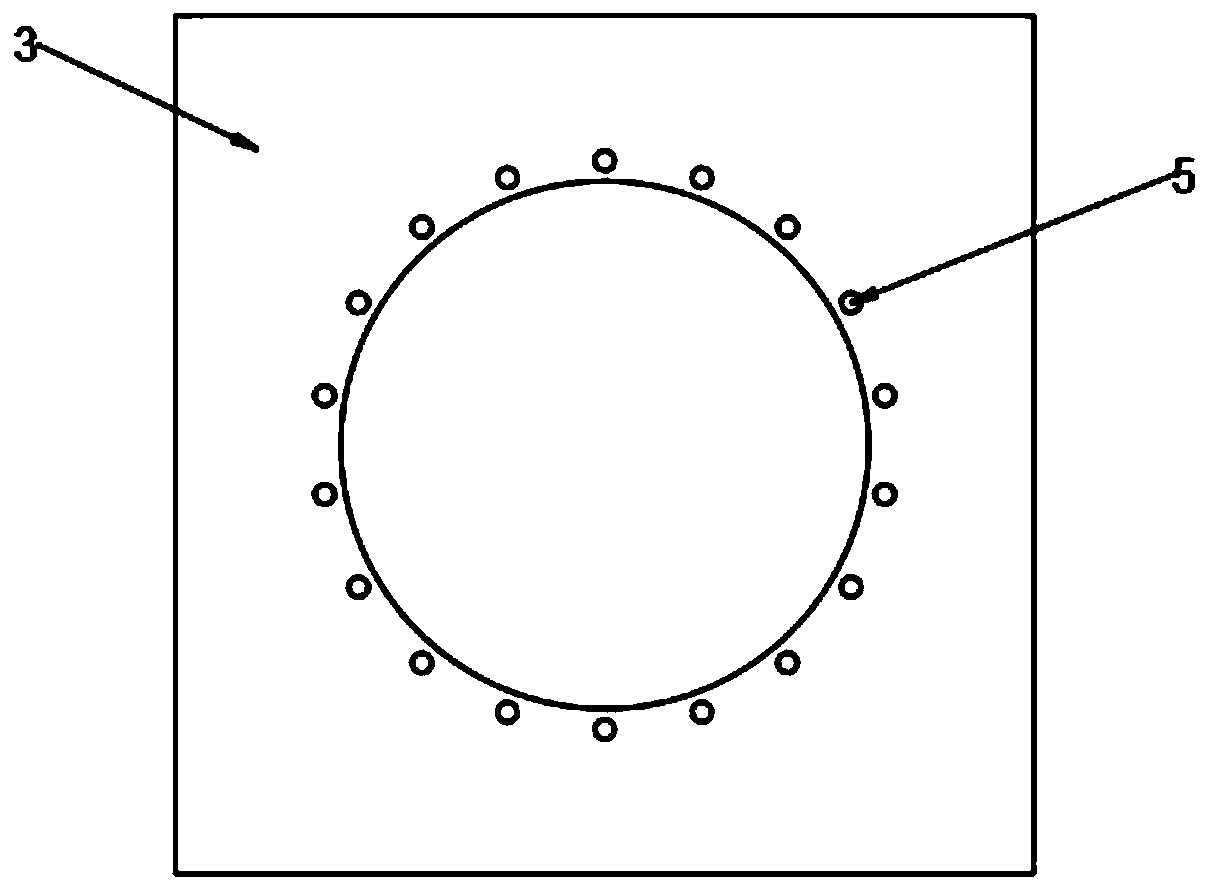

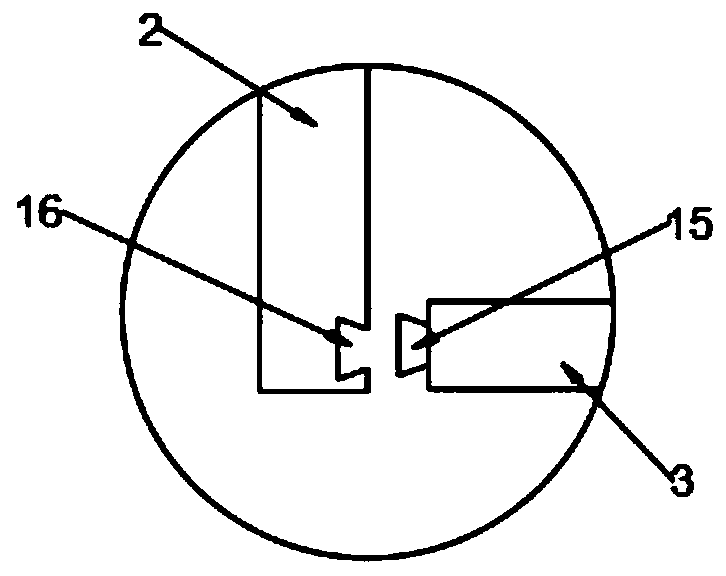

[0035] The outer mold device includes an outer mold base 1 and a steel bar skeleton 6, and the outer mold base 1 is formed into an open square cavity structure with a steel bar skeleton 6 installed inside; the outer mold base 1 is composed of two side templates 2, Two supporting baffles 3 and a bottom cushion 4 are enclosed, wherein the bottom cushion 4 is a cast-in-situ concrete structure at the bottom of the outer form base 1, and the upper surface is pre-embedded with embedded parts; the side formwork 2 is a long flat plate structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com