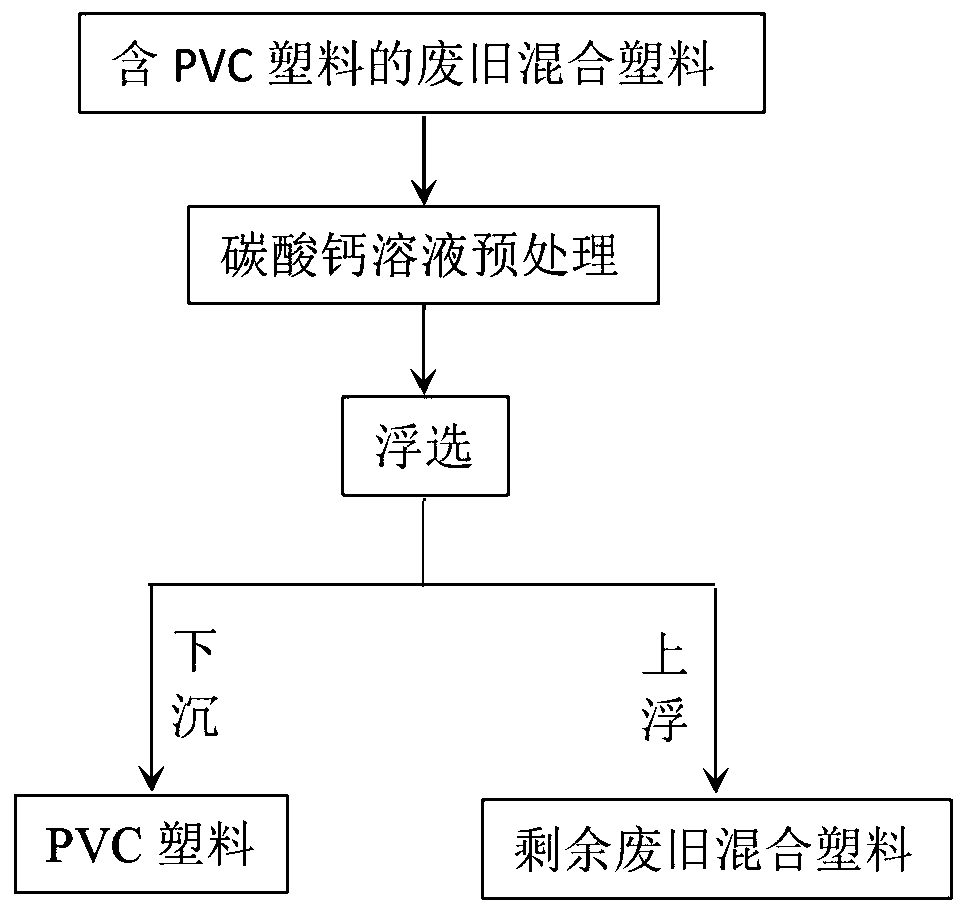

Method for floating and separating polyvinyl chloride from waste mixed plastics based on calcium carbonate pretreatment

A technology of mixing plastic and polyvinyl chloride, applied in the field of waste plastic recycling, can solve the problems of changing the chemical structure of the plastic surface layer, poor test reproducibility, etc., and achieve the effect of high selective separation, high recovery rate, and guaranteeing the stability of the process effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Clean and crush the mixed plastic of PC and PVC, take 10g of plastic particles with a particle size of 3-5mm (the mass ratio of PC:PVC is 1:1), and contain 0.4g / L CaCO at 60°C 3 Magnetic stirring is carried out in 100mL of the aqueous solution, the stirring time is 30min, the rotation speed is 800r / min, and the plastic particles obtained by filtration are subjected to flotation separation. After 3 minutes, PVC was separated by flotation with a purity of 97% and a recovery rate of 100%; PC had a purity of 100% and a recovery rate of 97%.

Embodiment 2

[0034] Wash and crush the mixed plastic containing PVC, PS and ABS, take 6g of plastic particles with a particle size of 3-5mm (the mass ratio of PVC:PS:ABS is 1:1:1), and use 100mL plastic at 40°C Concentration of 2g / L CaCO 3 The aqueous solution is pretreated, the stirring time is about 10min, the speed is 400r / min, and the flotation separation is carried out after filtration and cleaning. The applicable flotation conditions are 15mg / L of terpineol, 700mL / min of aeration, and 3min of flotation time. After flotation separation, the purity of the sinking product PVC is 95.6%, and the recovery rate is 100%, and the floating product is a mixture of ABS and PS.

Embodiment 3

[0036] Clean and crush the mixed plastics containing PVC, ABS, PS, PC and PET, take 10g of plastic particles with a particle size of 3-5mm (mass ratio 1:1:1:1:1), and put them under the condition of 50℃ , with 100mL of CaCO with a concentration of 5g / L 3 The aqueous solution was treated for 10 minutes, and the stirring speed during the treatment was 1000r / min. After filtration and cleaning, flotation separation was carried out. Afterwards, the floating product obtained is a mixture of ABS, PET, PS and PC, and the sinking product is PVC plastic, with a purity of 98.4% and a recovery rate of 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com