Preparation method of impurities in synthesis of cabozantinib malate

A technology for cabozantinib malate and impurities is applied in the field of preparation of impurities in the synthesis of cabozantinib malate to achieve the effect of high impurity purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

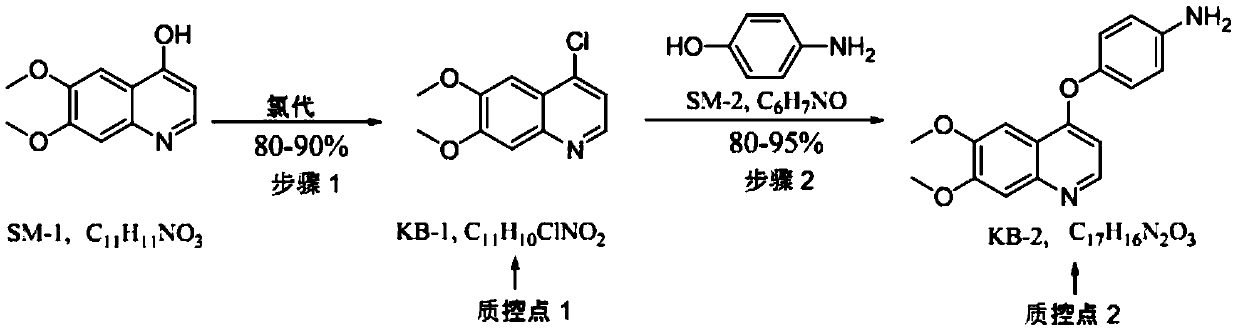

[0073] The impurity evolution process of cabozantinib malate:

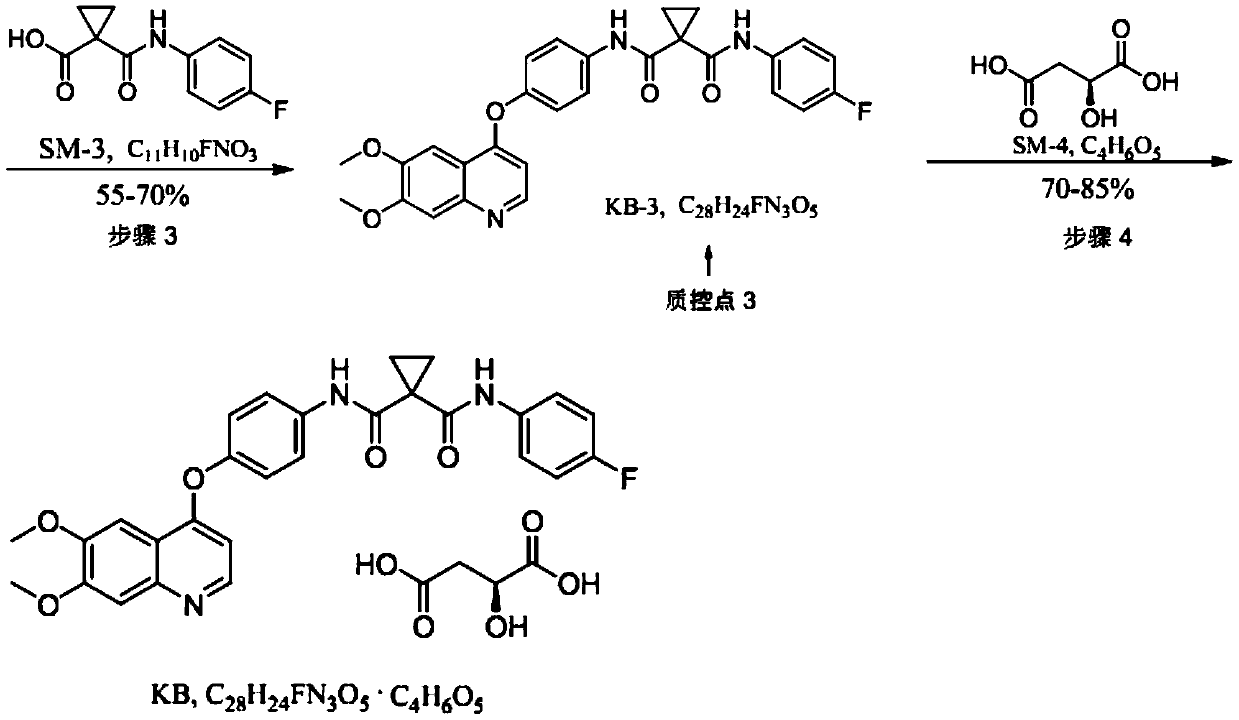

[0074] KB-2-A impurities: impurities introduced in step (2) nucleophilic substitution reaction.

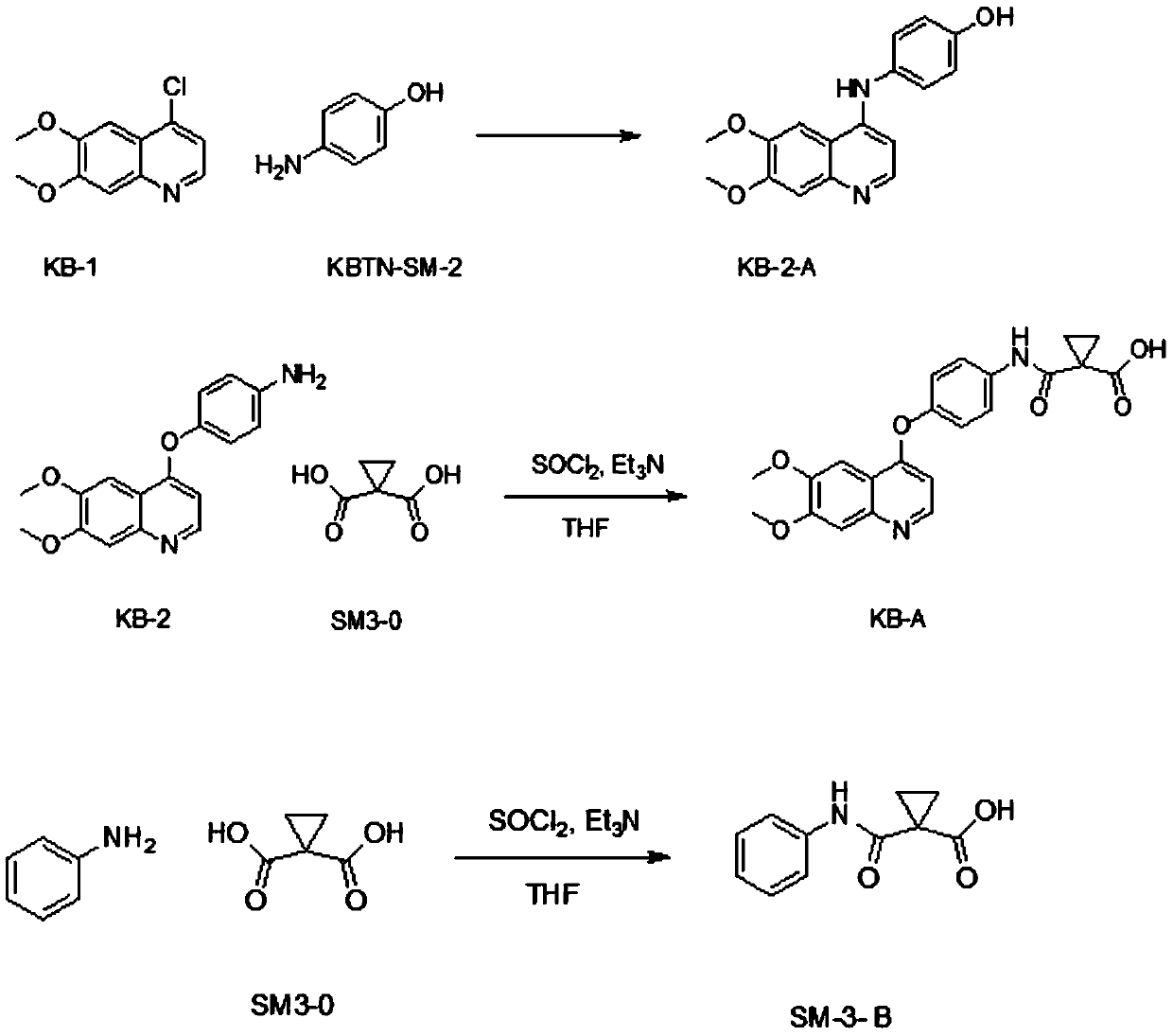

[0075] In this step reaction, KB-1 and p-fluoroaniline release a nucleophilic substitution reaction under alkaline conditions. When they are different bases or different solvents, two products KB-2 and KB-2-A will be generated. , see the following reaction:

[0076]

[0077] The control method of this impurity is as follows: can control the generation of KB-2-A by controlling reaction conditions, under this reaction conditions (potassium tert-butoxide / dimethyl subalkali), the generation amount of this byproduct is very little, after passing through Disposal can be removed.

[0078] During the establishment of the analytical method and quality control of intermediate KB-2, the existence of impurity KB-2-A was considered. The level of this impurity can be controlled by available analytical methods. Since the impu...

Embodiment 2

[0091] The preparation method of said KB-2-A comprises the steps of:

[0092] Step a, add KB-1, KBTN-SM-2, and isopropanol to reaction vessel A in sequence, heat to reflux for 5 hours, lower to room temperature, and stir for 14 hours;

[0093] Step b, suction filtration, 80ml of isopropanol rinses the filter cake;

[0094] Step c, add 180ml of diethyl ether to reaction vessel B, filter cake, stir at room temperature for 1 hour, filter with suction, and blow dry at 45°C for 2.5 hours to obtain a yellow solid which is KB-2-A impurity.

[0095] In this example, 13 g of yellow solid was obtained, the product purity was 97%, and the yield was 49.0%.

Embodiment 3

[0097] The preparation method of said KB-2-A comprises the steps of:

[0098] Step a, add KB-1, KBTN-SM-2, and isopropanol to reaction vessel A in sequence, heat and reflux for 5-7 hours, lower to room temperature, and stir for 14-18 hours;

[0099] Step b, suction filtration, 80-120ml of isopropanol rinses the filter cake;

[0100] Step c, add 180-220ml ether to reaction vessel B, filter the cake, stir at room temperature for 1-3 hours, filter with suction, and air-dry at 45-55°C for 1.5-2.5 hours to obtain a yellow solid which is KB-2-A Impurities (KB-2-A4-[(6,7-Dimethoxy-4-quinolyl)amino]phenol CAS: 748707-58-6 Molecular weight: 296.32); KB-1, KBTN-SM-2 and The feeding ratio of isopropanol is 20g: 12g: 200ml.

[0101] In this example, 12 g of yellow solid was obtained, the product purity was 96%, and the yield was 45.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com