Preparation method of coupling agent gas phase modified graphite nanosheet composite powder

A technology of graphite nanosheets and composite powders, applied in the directions of graphite, chemical instruments and methods, dyed organosilicon compound processing, etc., can solve the problems of many operation procedures and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

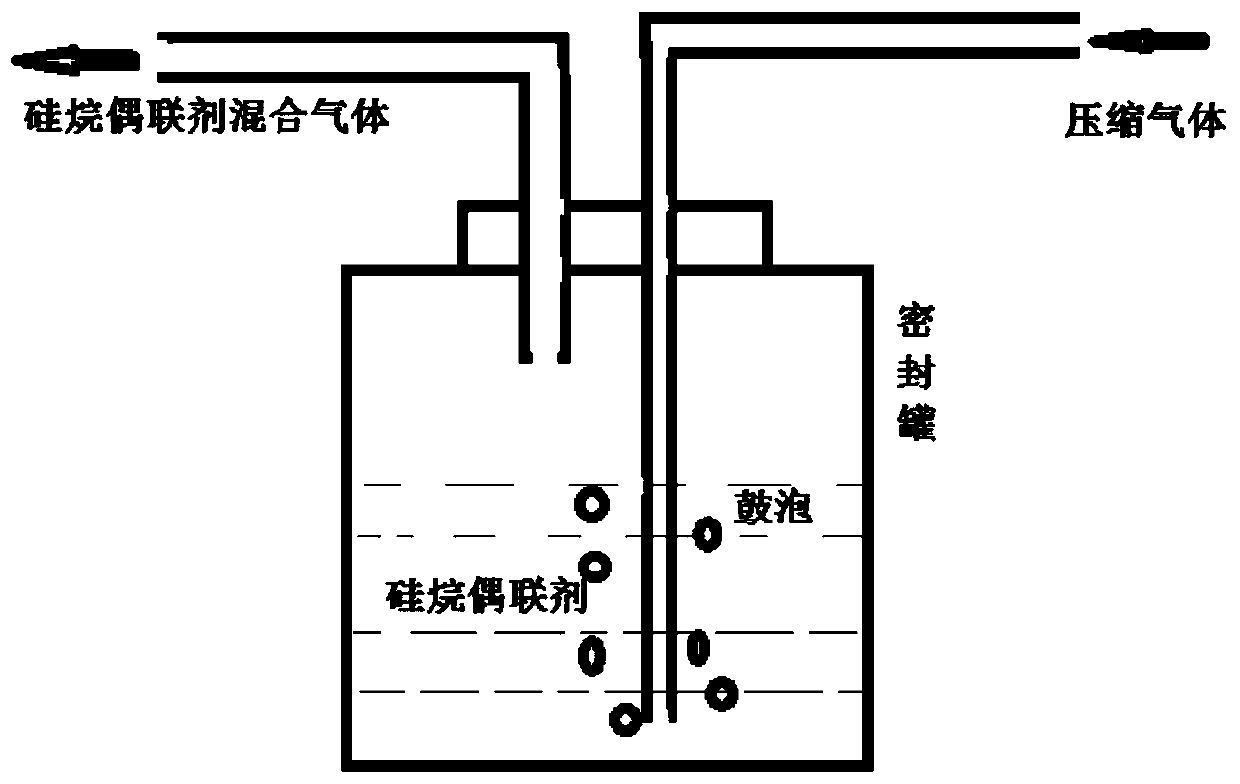

[0017] A preparation method of silane coupling agent and graphite nanosheet composite powder, which is carried out as follows: take 1 liter of commercially available KH560 silane coupling agent solution, put figure 1 In the tank shown, use a commercially available air pump from figure 1 In the direction indicated by the arrow, the compressed air is input into the silane coupling agent liquid to bubble, and after the airtight tank is filled with the mixed gas, the expanded graphite and the coupling agent are mixed by the inlet of the fluidized bed jet mill using negative air pressure. The mixed gas is sent into the crushing chamber at the same time. In the crushing chamber, the expanded graphite collides at a high speed under the coupling agent atmosphere, and the coupling agent molecules are attached to the surface of the crushed graphite nanopowder. After classification by the classifier, the silane-modified graphite nanopowder is collected.

Embodiment 2

[0019] A preparation method of titanate coupling agent and graphite nanosheet composite powder, which is carried out as follows: take 1 liter of commercially available 201 titanate coupling agent solution, put figure 1 In the tank shown, use a commercially available air pump from figure 1 Inlet in the direction indicated by the arrow, input compressed air into the titanate coupling agent liquid for bubbling, the selected commercially available coupling agent is in a dilute solution state, and the compound atmosphere of the coupling agent can be realized by bubbling with an air pump; airtight tank After the mixed gas is filled, the mixed gas of expanded graphite and coupling agent is sent into the crushing chamber at the same time through the inlet port of the fluidized bed jet mill by negative air pressure. In the crushing chamber, the expanded graphite is in the atmosphere of the coupling agent, A high-speed collision occurs, and at the same time, the coupling agent molecules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com