Photosynthetic microorganism cultivation production system

A technology for photosynthetic microorganisms and production systems, applied in the field of photosynthetic microorganisms cultivation and production systems, can solve problems such as air cannot be effectively purified, microorganisms grow in distress, and be drawn out of the tube, so as to achieve automatic cleaning, avoid disassembly and cleaning methods, and improve cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

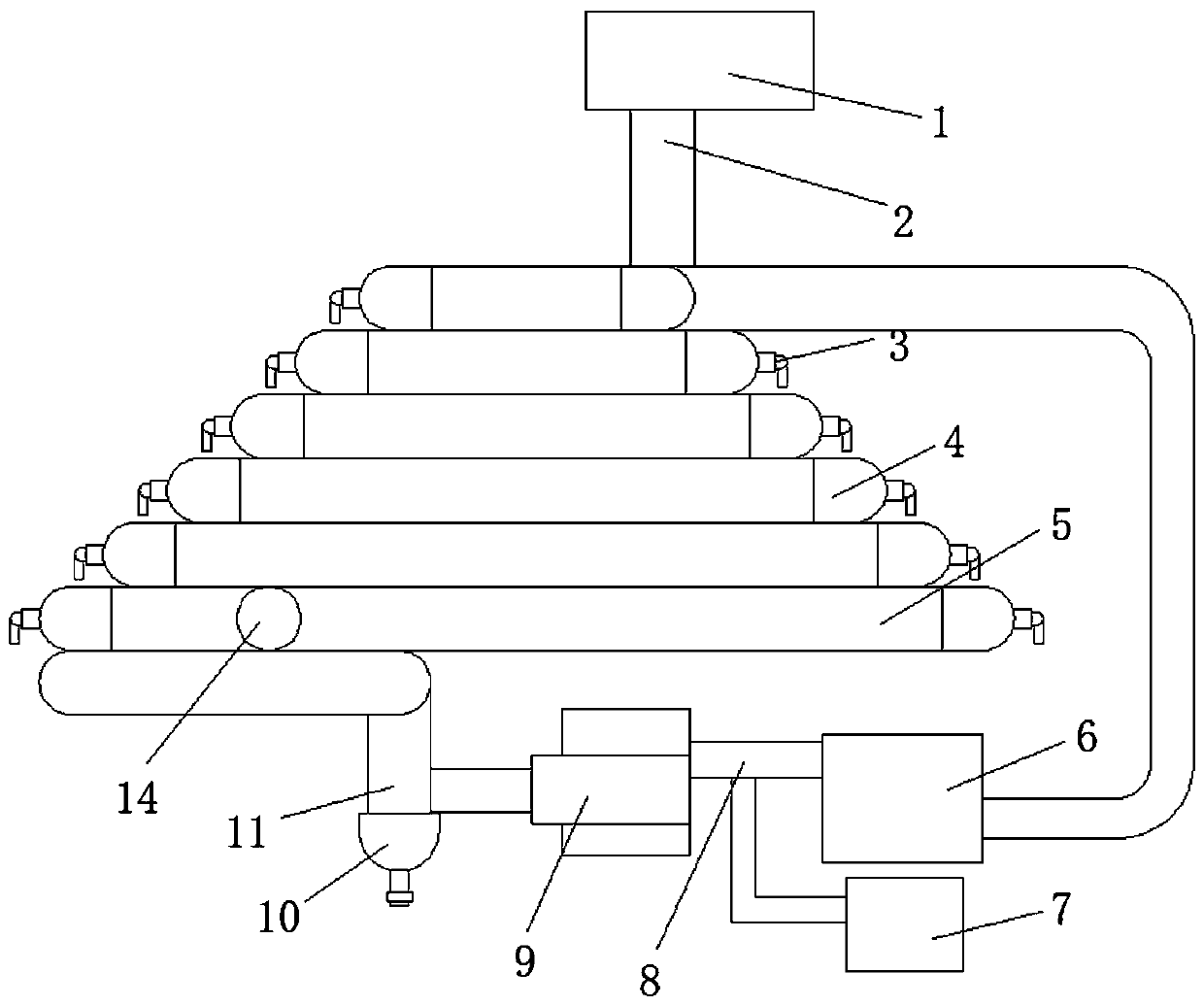

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

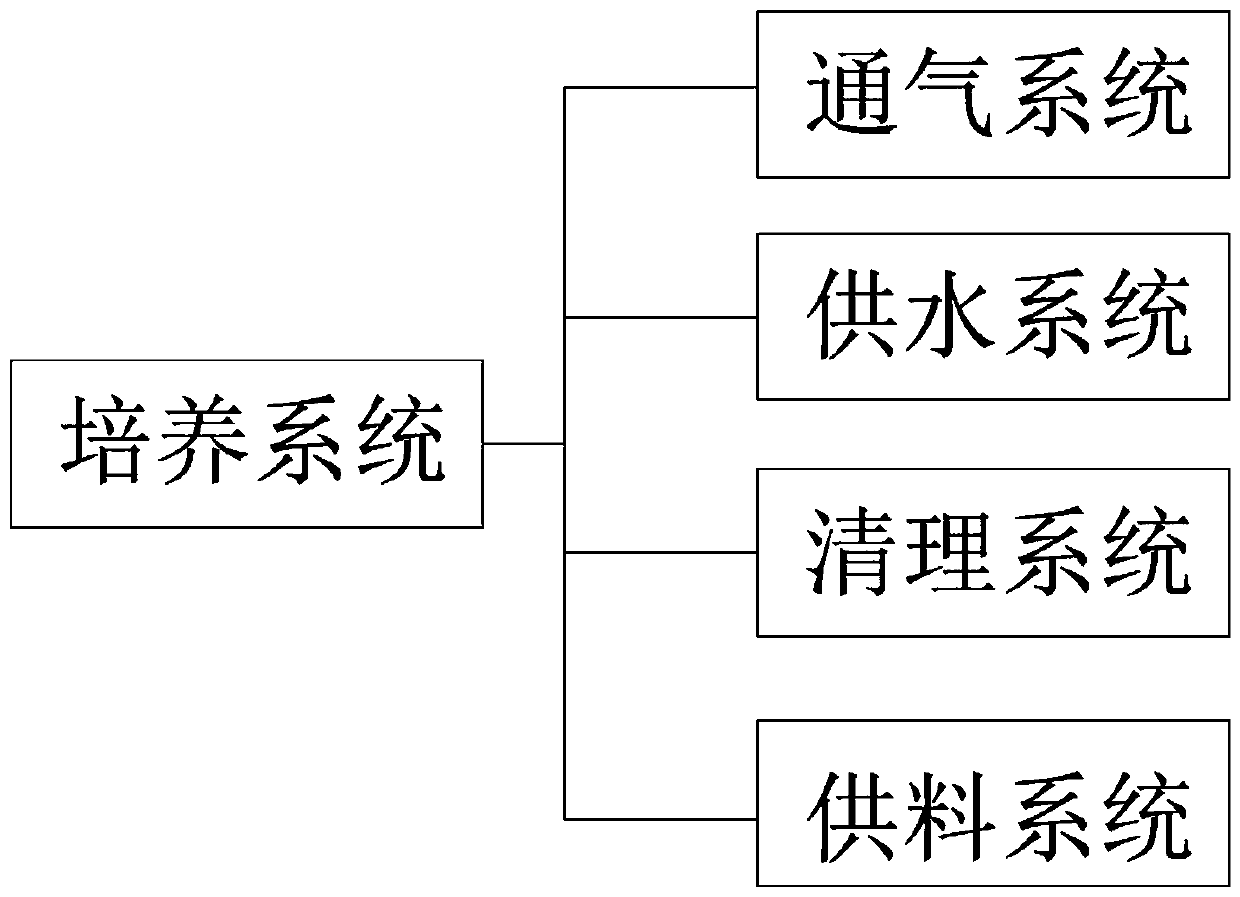

[0034] Such as Figure 1-4 As shown, the present invention provides a kind of technical scheme: a kind of photosynthetic microorganism culture production system, comprises

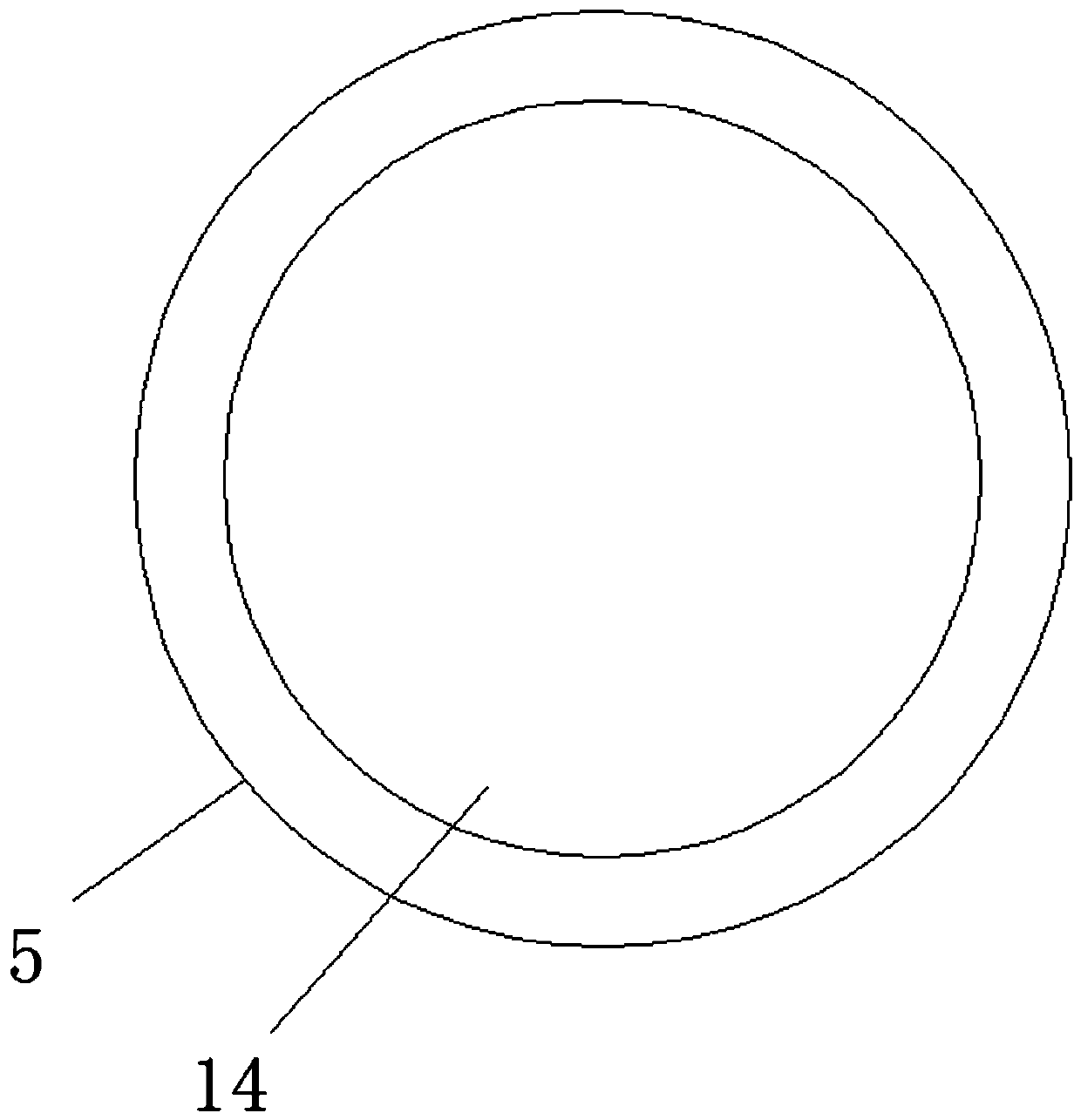

[0035] Ventilation circulation system, said ventilation circulation system includes air supply unit, ventilation pipeline unit, rubber ball 14 and valve, said air supply unit includes air extraction device 1, air supply end purification equipment 9 and air pressure precision detection and control instrument, The air pressure precision detection and control instrument is installed at both ends of the cultivation pipeline 5, and the air extraction device 1 adopts active air pressure filtration and purification equipment to accurately supply air. ±50Pa, the air extraction device 1 and the gas supply end puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com