Modified perfluorosulfonic acid composite membrane and preparation method thereof, fuel cell and electric appliance

A perfluorosulfonic acid and composite membrane technology, applied in fuel cells, power system fuel cells, electrochemical generators, etc., can solve the problem that the proton conductivity of perfluorosulfonic acid membranes needs to be improved, and achieve improved and stable conductivity Good performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a modified perfluorosulfonic acid composite membrane, comprising:

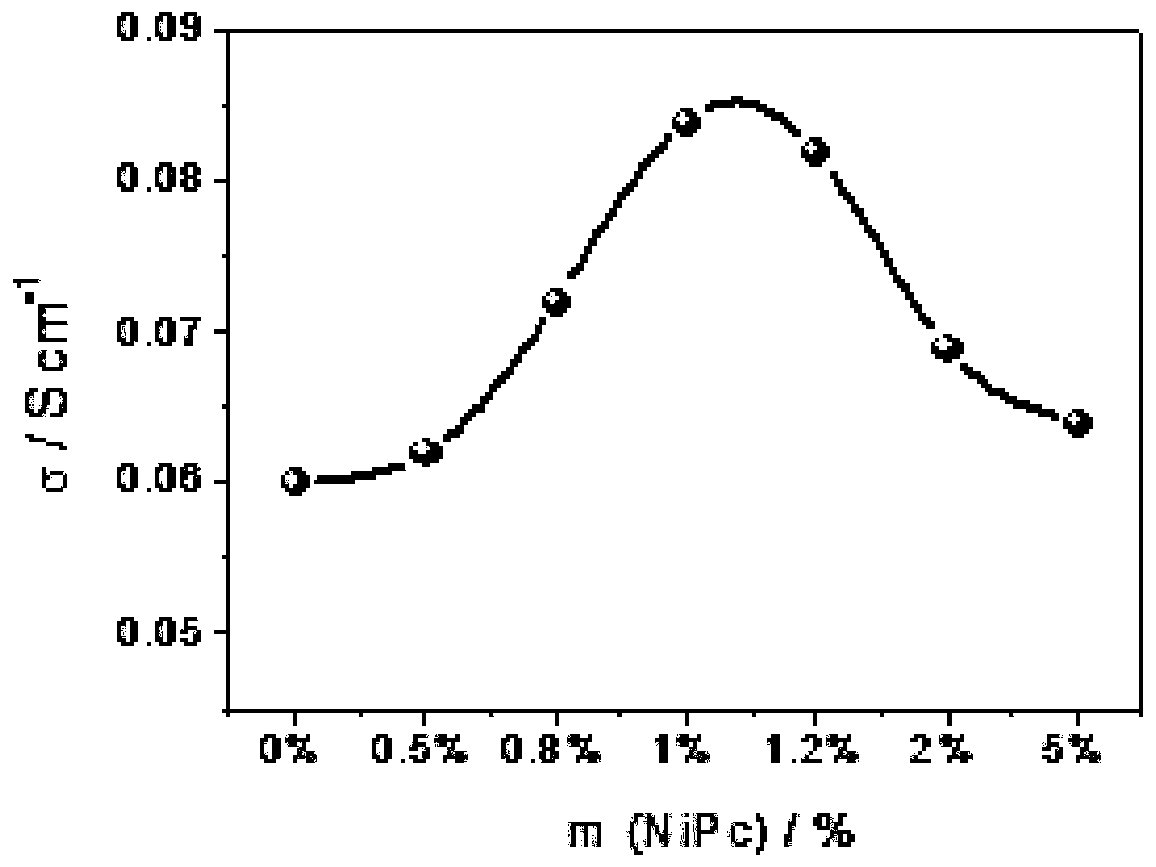

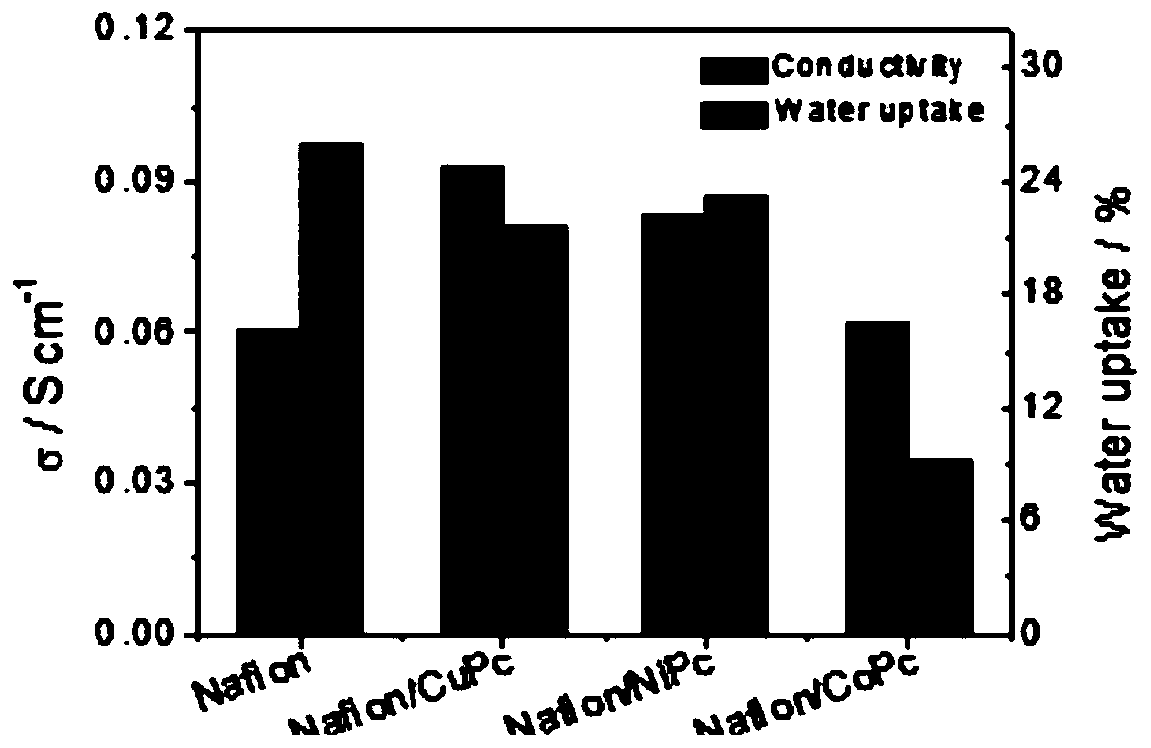

[0034] The film-forming solution containing metal phthalocyanine and perfluorosulfonic acid is heated to form a film, the metal phthalocyanine includes at least one of copper phthalocyanine, nickel phthalocyanine and cobalt phthalocyanine, the mass ratio of metal phthalocyanine to perfluorosulfonic acid 0.8 to 2:100.

[0035] Specifically:

[0036] Weigh a certain amount of perfluorosulfonic acid stock solution, dilute it with a solvent to a perfluorosulfonic acid solution with a mass fraction of 5%, stir and mix evenly. The solvent used in this step is ethanol, and dilution with ethanol can ensure subsequent film formation.

[0037] Dissolve the metal phthalocyanine in ethanol, stir evenly until the metal phthalocyanine dissolves, then add the metal phthalocyanine solution to the diluted perfluorosulfonic acid solution, mix and stir to obtain a uniform solution to obtain a film...

Embodiment 1

[0043] This example provides a method for preparing a modified perfluorosulfonic acid composite membrane:

[0044] Take 10 g of 20% perfluorosulfonic acid solution by mass and dilute it with ethanol to obtain a solution with 5% perfluorosulfonic acid by mass. 0.02 g of nickel phthalocyanine was dissolved in ethanol to obtain a nickel phthalocyanine solution, and the nickel phthalocyanine solution was added to the diluted perfluorosulfonic acid solution to obtain a film-forming solution.

[0045] Take 10ml of the film-forming solution in a glass petri dish, heat and dry at 100°C to form a film. The mass percent content of nickel phthalocyanine in the composite film is 1%.

Embodiment 2-6

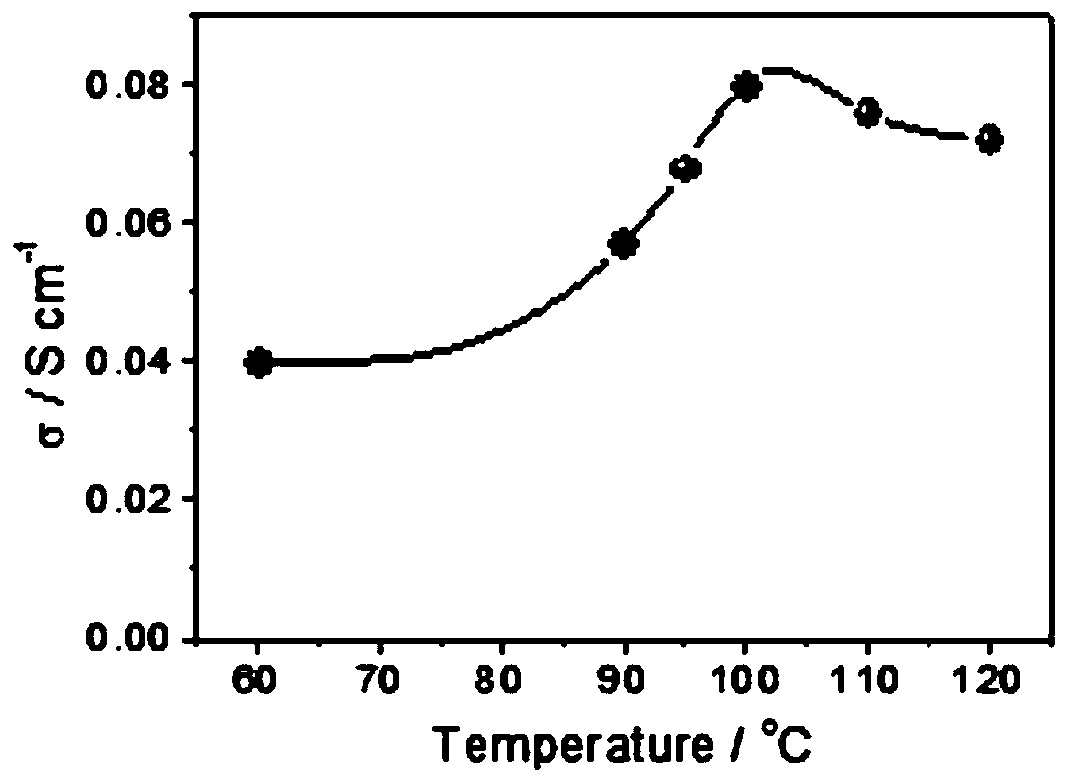

[0047] Examples 2-6 are basically the same as Example 1, except that the heating and drying film-forming temperatures are: 60°C, 90°C, 95°C, 110°C, and 120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com