Direct-drive power generation control method for sensorless permanent magnet motor

A permanent magnet motor, power generation control technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve the problems of vibration, small inrush current, and no solution to high-speed vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

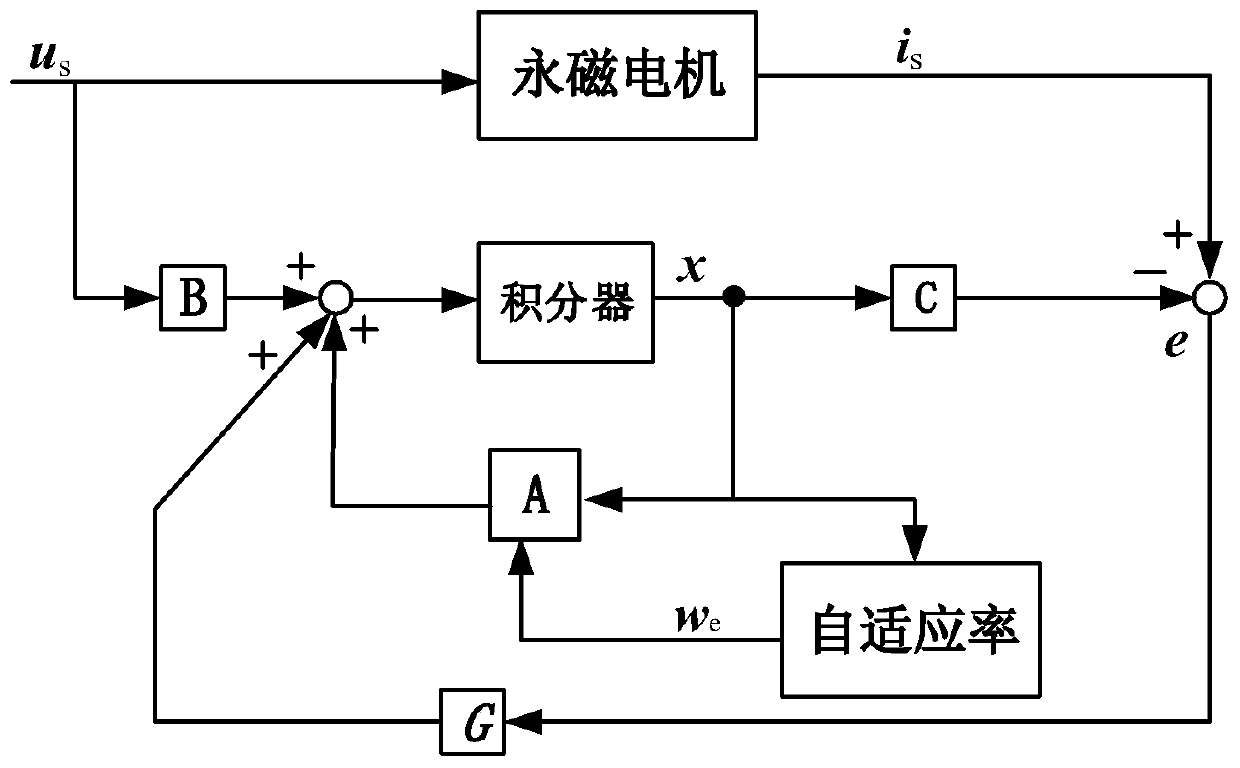

[0054] The present invention is further described below with reference to the accompanying drawings and specific embodiments.

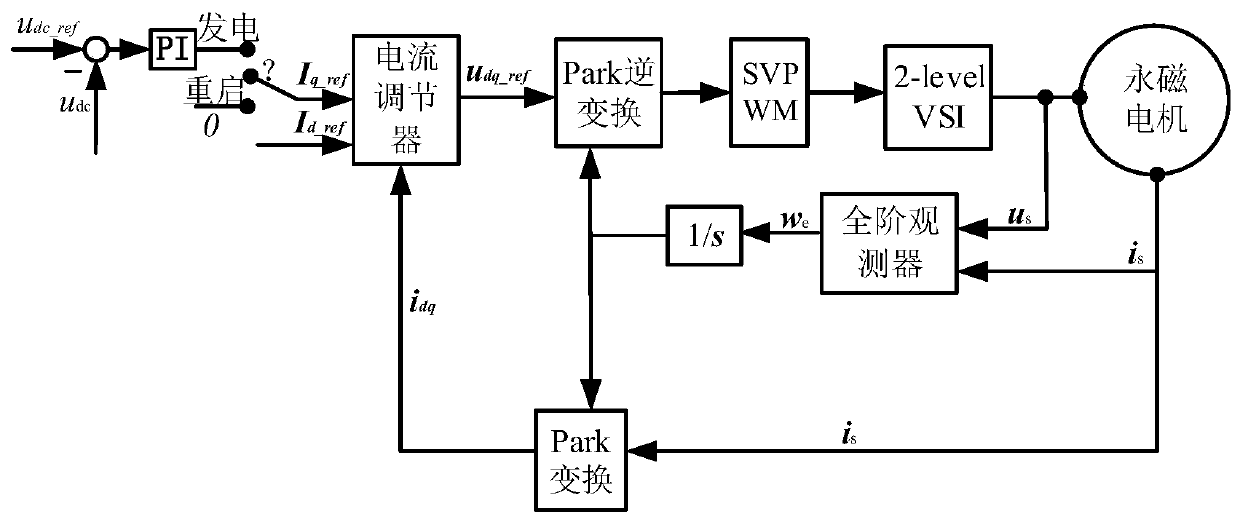

[0055] In the following embodiments, a permanent magnet motor is used as an example for the AC motor, and a two-level voltage inverter is used as an example for the inverter. The present invention is further described below through the control process of the above embodiment of the AC motor.

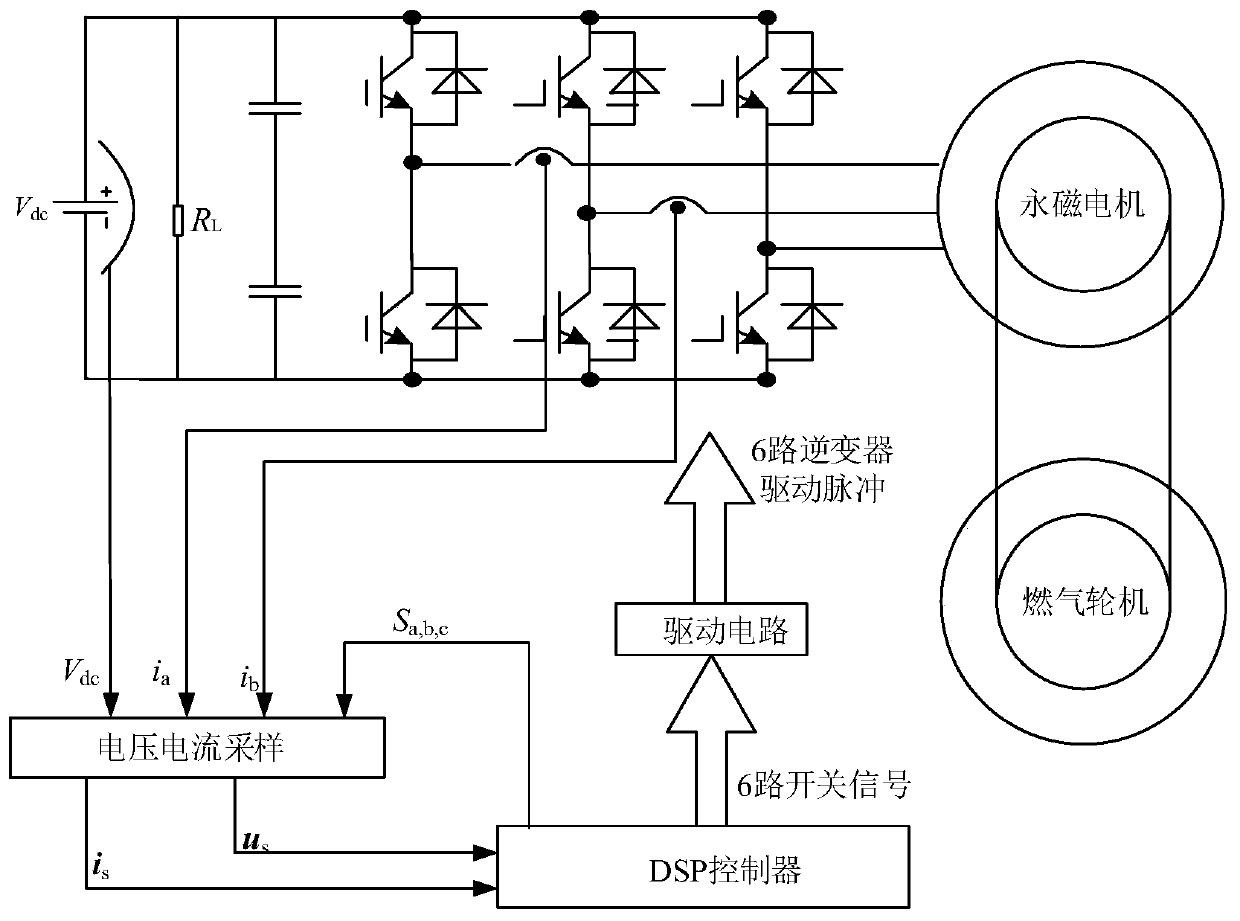

[0056] like figure 1 As shown, the permanent magnet motor system applying the present invention includes a gas turbine, a permanent magnet motor, a three-phase inverter, a DC side capacitor, a load resistance, a voltage and current sampling circuit, a DSP controller and a drive circuit. The voltage and current sampling circuit uses the voltage Hall sensor and the current Hall sensor to collect the DC side bus voltage and the a and b phase currents of the permanent magnet motor respectively. The DSP processor completes the operation of the method of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com