High mechanical durable super-hydrophobic/oil coating with bionic structure and preparation method of high mechanical durable super-hydrophobic/oil coating

A durable and super-hydrophobic technology, used in coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve the problems of wear resistance, difficult application, easy damage, etc. The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

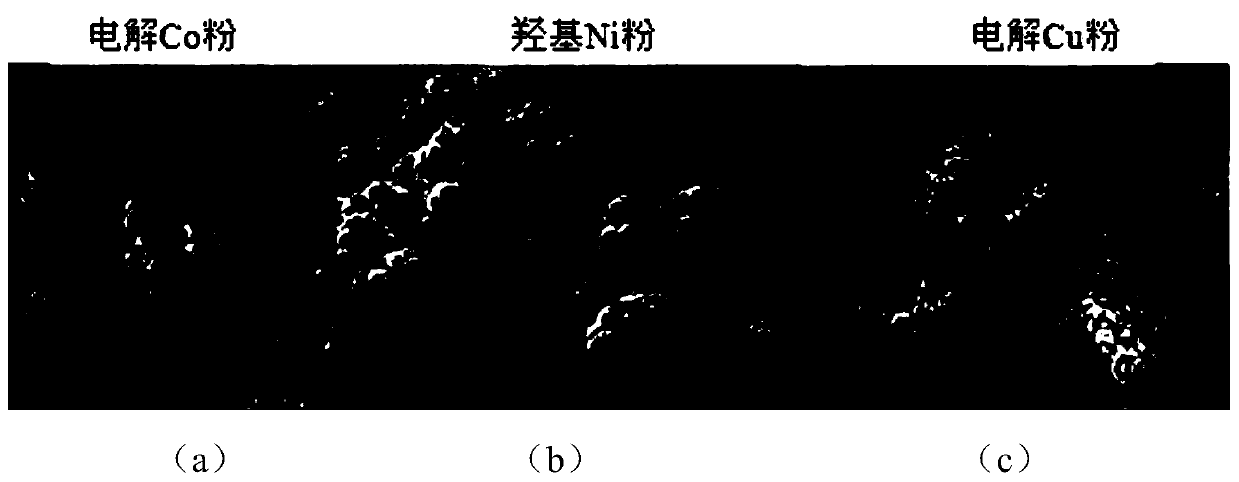

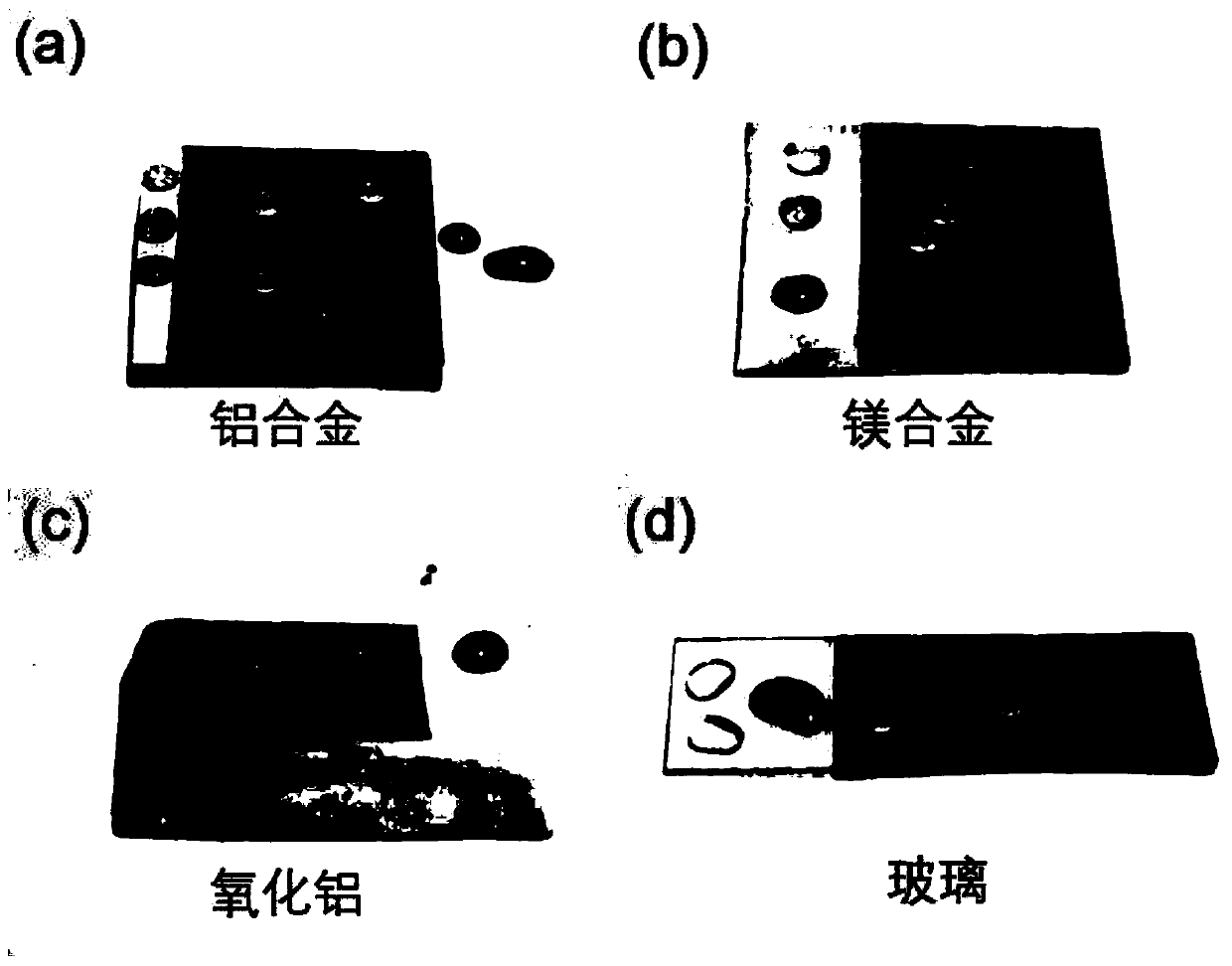

[0036] Based on aluminum alloy, magnesium alloy, glass and alumina, such as figure 1 The shown electrolytic Cu powder with a particle size of 15-50 microns is used as a raw material, and the preparation method is as follows:

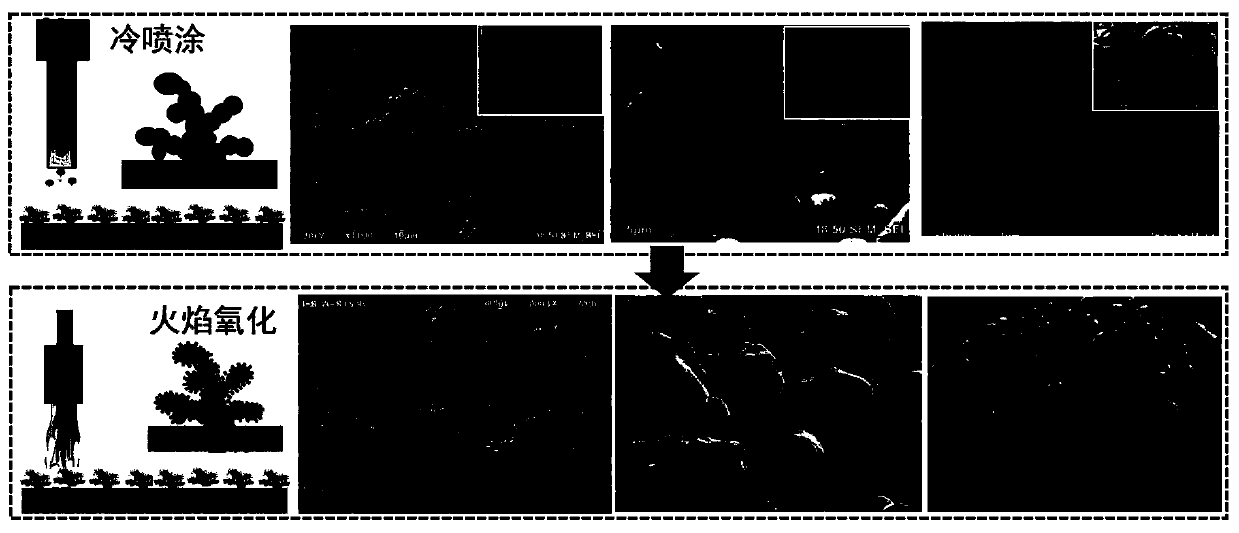

[0037] First, cold spraying was used to prepare metal coatings with coral reef-like flexible micro-rough structures on the surface of different substrates. Before cold spraying, the surface of the substrate was cleaned and dried with acetone. In the process of cold spraying, nitrogen is used as the accelerating gas. The gas pressure is 2.5MPa, the gas temperature is 370°C, the powder feeding rate is 25g / min, and the moving speed of the spray gun is 800mm / s. The cold spray gun scans the surface of the substrate in a zigzag shape. The coating is deposited under the parameter conditions that the distance between spraying lines is 5mm and the spraying distance is 40mm.

[0038] Subsequently, an oxyacetylene flame is used to scan the surface of the cold-spra...

Embodiment 2

[0043] Aluminum alloy, magnesium alloy, glass and alumina are used as substrates, and the morphology is as follows: figure 1 The shown particle size is electrolytic Ni powder of 20-80 microns as raw material, and the preparation method is as follows:

[0044] First, cold spraying is used to prepare a metal coating with a coral reef-like flexible micron-rough structure on the surface of the substrate. Before cold spraying, the substrate surface is cleaned and dried with acetone. In the process of cold spraying, nitrogen is used as the accelerating gas. The gas pressure is 2.0MPa, the gas temperature is 420°C, the powder feeding rate is 40g / min, and the moving speed of the spray gun is 1000mm / s. The cold spray gun scans the surface of the substrate in a zigzag shape. The coating is deposited under the parameter conditions that the distance between spraying lines is 5mm and the spraying distance is 40mm.

[0045] After the spraying is completed, directly use a 0.5% stearic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com