Electrode shape regulatable CMUTs (capacitive micromachined ultrasonic transducers) with high ultrasonic transceiving performance

An electrode shape and superb technology, applied in the direction of the fluid using vibration, can solve the problems of reducing the spatial range of film motion, film thickness uniformity, unit structure consistency, increasing the complexity of the preparation process, etc., to achieve ultrasonic emission intensity and reception. The sensitivity, ultrasonic emission intensity and ultrasonic receiving sensitivity are improved, and the consistency is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

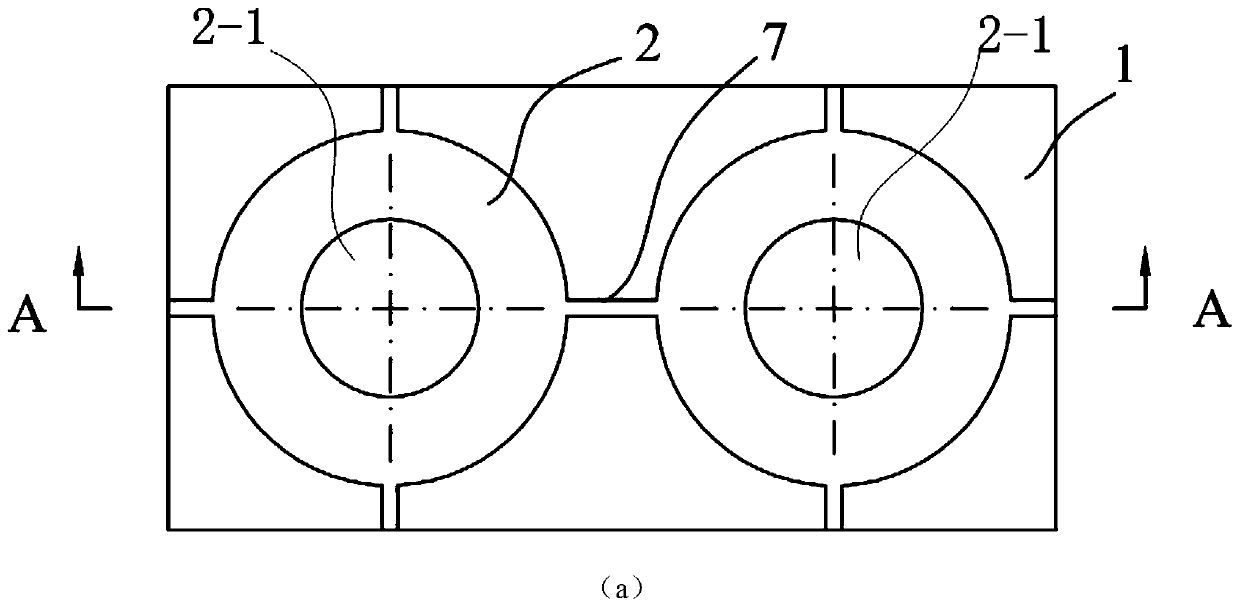

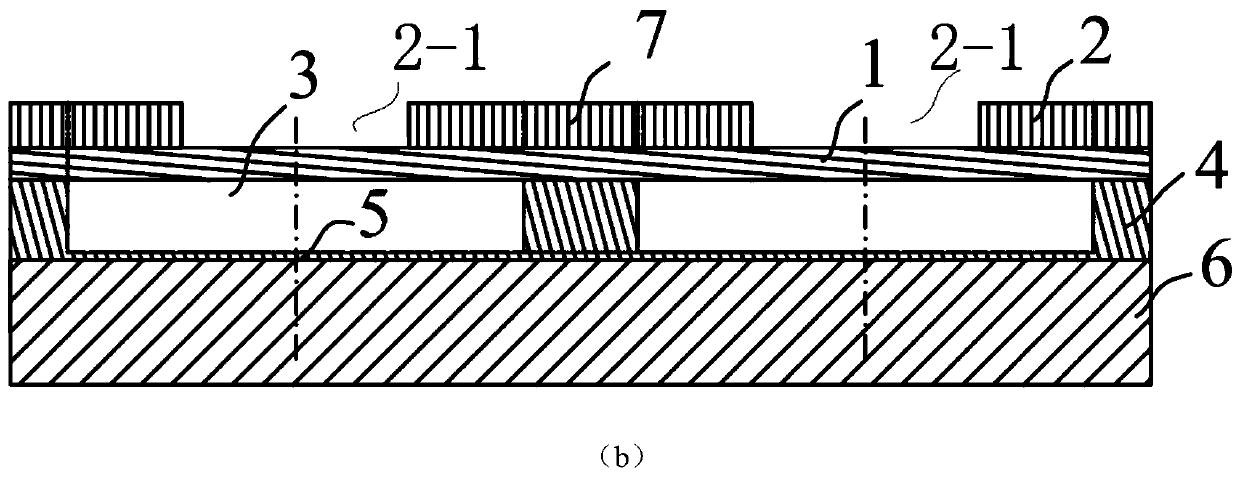

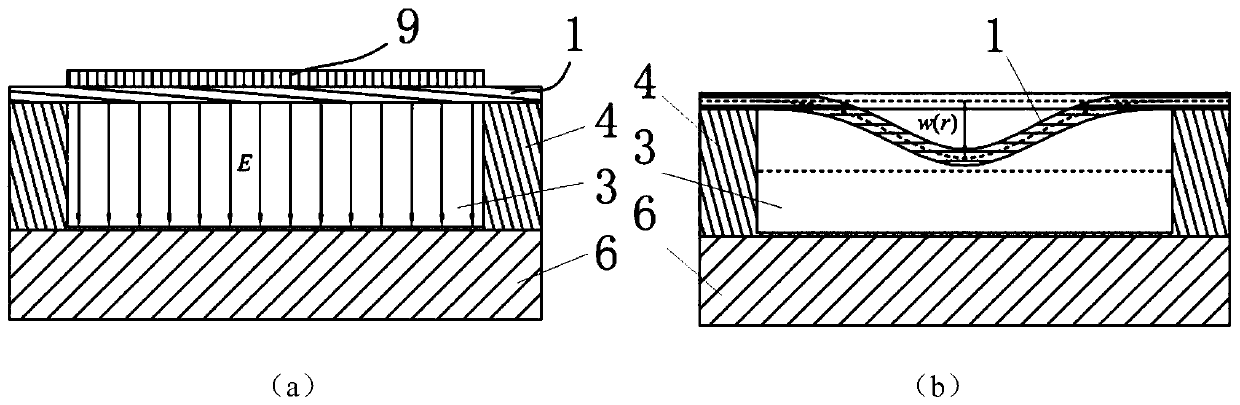

[0023] Referring to Fig. 1(a) and Fig. 1(b), the overall structure of the high ultrasonic transceiving performance CMUTs regulated by the electrode shape of the present invention includes, from top to bottom, a hollow electrode 2, a suspended film 1, a cavity 3, a lower electrode insulating layer 5 and The lower electrode 6, the hollow electrode 2 is used as the upper electrode, the central area of the hollow electrode 2 is provided with a through hole 2-1 through the thickness of the electrode, the central axis of the through hole 2-1 coincides with the central axis of the cavity 3; the suspended film 1 Together with the hollow electrodes 2, the vibrating membrane of CMUTs is formed, the cavity 3 is surrounded by pillars 4, and the hollow electrodes 2 of each CMUTs unit are connected by electrode connecting lines 7.

[0024] Referring to the embodiment shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com