Preparation method of flaky iron phosphate, the prepared flaky iron phosphate and application of the flaky iron phosphate

A technology of iron phosphate and lithium iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of poor grinding efficiency and high S content, achieve high grinding efficiency, reduce S content, and high discharge capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 of the present invention is: a kind of preparation method of flaky ferric phosphate, comprises the following steps:

[0031] (1) Prepare 4 L of 1.5 mol / L iron salt, add 0.6 mol of sulfuric acid, and slowly add 500 g of hydrogen peroxide (27% by mass) solution into the iron salt until the oxidation is complete.

[0032] (2) Weigh 795.5g of phosphoric acid (commercially available concentrated phosphoric acid, mass fraction 85%), weigh 720g of sodium hydroxide and add it to the phosphoric acid and make the volume to 4L.

[0033] (3) Pour the prepared phosphorus salt into a 10L reactor and raise the temperature to 96°C, and add the prepared iron salt into the phosphorus salt at a rate of 1L / h.

[0034] (4) The sample is calcined and crystallized in an atmosphere furnace at 550° C. for 5 hours to obtain the flaky iron phosphate.

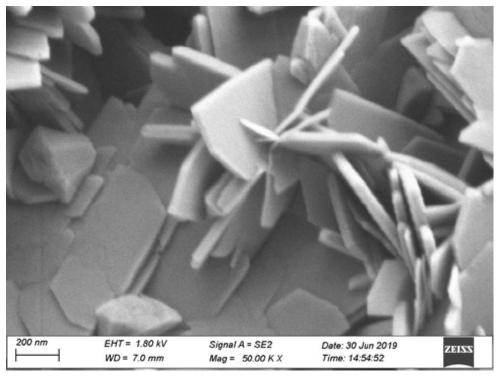

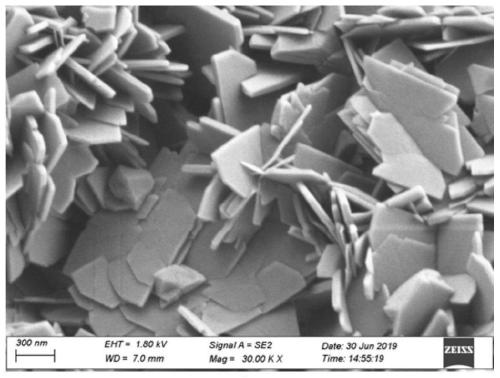

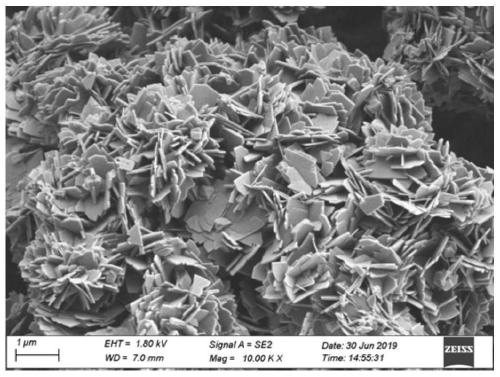

[0035] (5) Observing the microscopic morphology of the sheet-shaped iron phosphate obtained by the above-mentioned operation through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com