A fe that can be used for magnetic hyperthermia 3 o 4 Preparation method of nanorod material

A technology of nanorods and thermotherapy agent, which is applied in the field of biomedical application of nanomaterials, can solve the problems of lack of magnetocaloric properties of nanorod materials, and achieve the effects of less uncontrollable factors, good magnetocaloric properties, and increased heating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

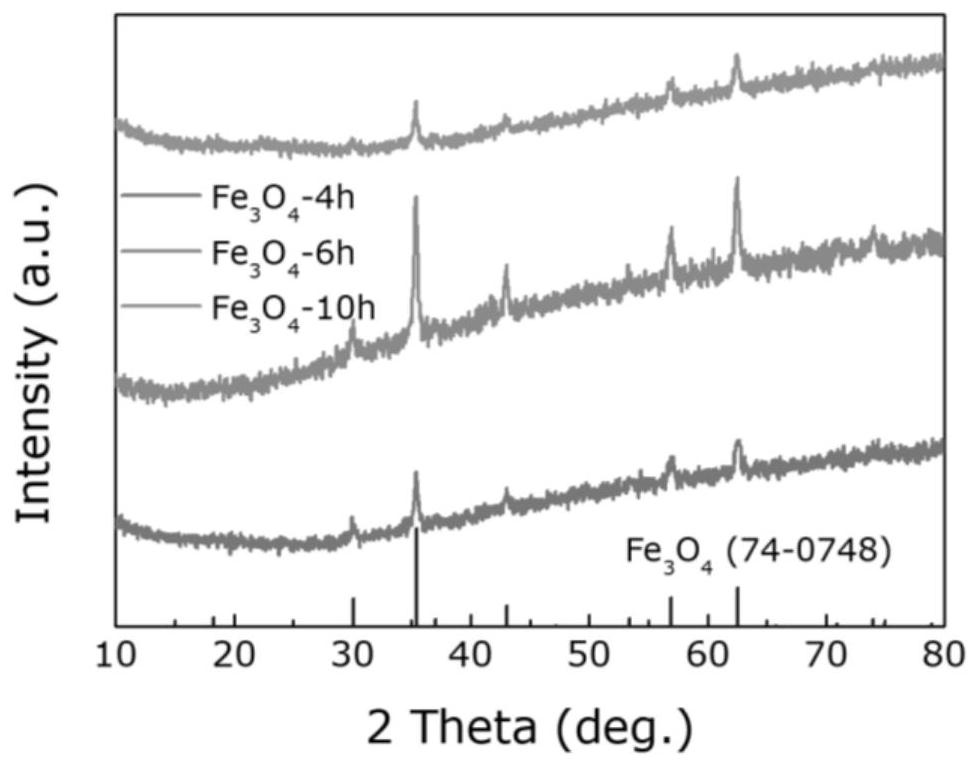

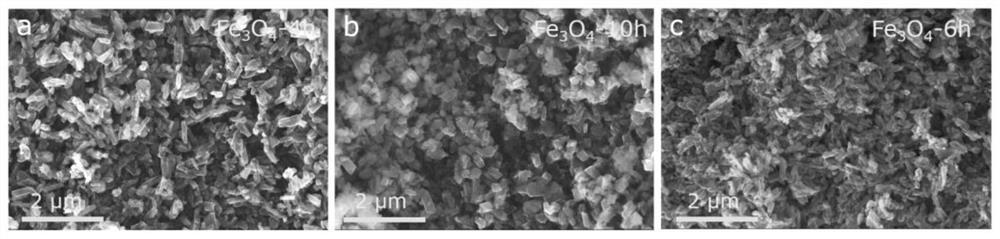

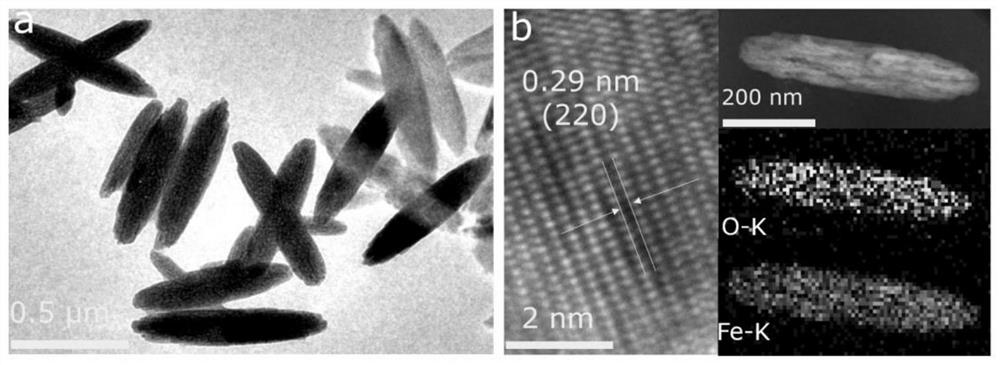

Embodiment 1

[0027] Weighing 1.6G FECL 3 · 6h2 O and dissolved in 60 mL of deionized water, the formulated solution was transferred to a high pressure hydrothermal reactor having a volume of 100 mL. Then, the reaction kettle was placed in an oven at a temperature of 100 ° C for 4 h, naturally cooled to room temperature. The yellow precipitate obtained by the experiment was subsequently washed 3 times with ionized water and alcohol, centrifuged and dried at 60 ° C to give a yellow powder β-FeoOH, which was named FeooH-4H. Subsequently, 20 mg of beta-FeOOH powder was weighed, and they were placed in 6 ml of tripermine, and the ultrasonic cleaning washable was easily dispersed in three octamines. 200 μl of oleic acid was added to the suspension obtained after dispersion, stirred for 1 h, and then transferred to the centrifuge, and centrifuge at 7500 rpm for 5 min to obtain a glue mixture. Transfer the above mixture to a sealed high temperature tube furnace, and AR / H is introduced into the cooke...

Embodiment 2

[0030] Weighing 1.6G FECL 3 · 6h 2 O and dissolved in 60 mL of deionized water, the formulated solution was transferred to a high pressure hydrothermal reactor having a volume of 100 mL. The reactor was then placed in an oven at a temperature of 100 ° C for 10 h, naturally cooled to room temperature. The yellow precipitate obtained by the experiment was subsequently washed 3 times with ion and alcohol, centrifuged and dried under 80 ° C to give a yellow powder β-feoOH, which was named FeOH-10H. Subsequently, 20 mg of β-FeOOH powder was weighed, and they were placed in 6 mL of triperlamine, and the ultrasonic cleaning washable was easily dispersed in three octamines. 200 μl of oleic acid was added to the suspension obtained after dispersion, stirred for 2 h, and then transferred to the centrifuge, centrifugation at 7500 rpm to obtain a glue mixture. Transfer the above mixture to a sealed high temperature tube furnace, and AR / H is introduced into the cooker. 2 Mixed atmosphere (wh...

Embodiment 3

[0033] Weighing 1.6G FECL 3 · 6h 2 O and dissolved in 60 mL of deionized water, the formulated solution was transferred to a high pressure hydrothermal reactor having a volume of 100 mL. The reactor was then placed in an oven at a temperature of 100 ° C for 6 h, and naturally cooled to room temperature. The yellow precipitate obtained by the experiment was then cleaned with ionized water and alcohol, centrifugally, and dried under 60 ° C to give a yellow powder β-feoOH, which was named FeOH-6H. Subsequently, 20 mg of β-FeOOH powder was weighed, and they were placed in 6 mL of triectine, and the ultrasonic cleaning washable was solened to uniformly dispersed in three octamines. 200 μl of oleic acid was added to the suspension obtained after dispersion, stirred for 1 h, and then transferred to a centrifuge, and centrifuged at 8500 rpm to obtain a glue mixture. Transfer the above mixture to a sealed high temperature tube furnace, and AR / H is introduced into the cooker. 2 Mixed atmo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com