Formula and production technology of red brick-containing recycled aggregate permeable concrete

A technology of permeable concrete and recycled aggregate, applied in the field of permeable concrete, can solve the problem that the technical index requirements of red brick particles are not given, and the concrete does not have water permeability, water storage, influence water storage, water permeability, ventilation, etc. performance and other issues, to achieve the effect of alleviating the urban heat island effect, conducive to healthy development and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

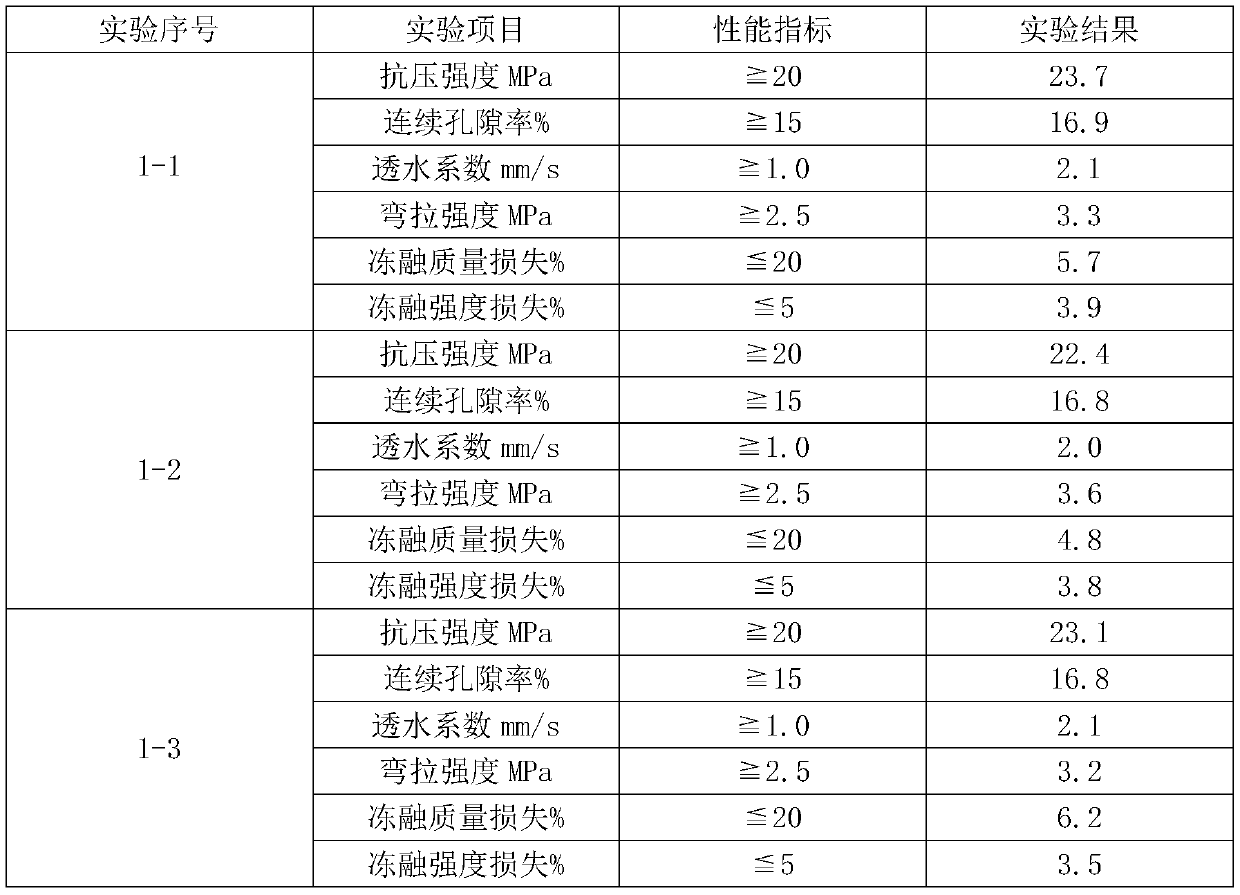

Embodiment 1

[0056] Example 1: A formula of recycled aggregate permeable concrete containing red bricks The raw materials for the preparation of recycled aggregate permeable concrete containing red bricks in this example include the following components in parts by weight: 300 parts of ordinary portland cement , 840 parts of natural crushed stone, 360 parts of recycled aggregate containing red brick, 11 parts of permeable cement, 0.9 part of water reducing agent, and 0.45 part of polypropylene fiber.

[0057] The production process of recycled aggregate permeable concrete containing red bricks carried out by raw materials includes the following steps:

[0058] a. Transport the classified and cleared construction waste containing red bricks to the construction waste disposal site, use mobile impact crusher and screening equipment to process the construction waste, and remove the construction waste containing red bricks through debris separation and magnetic separation during the screening pr...

Embodiment 2

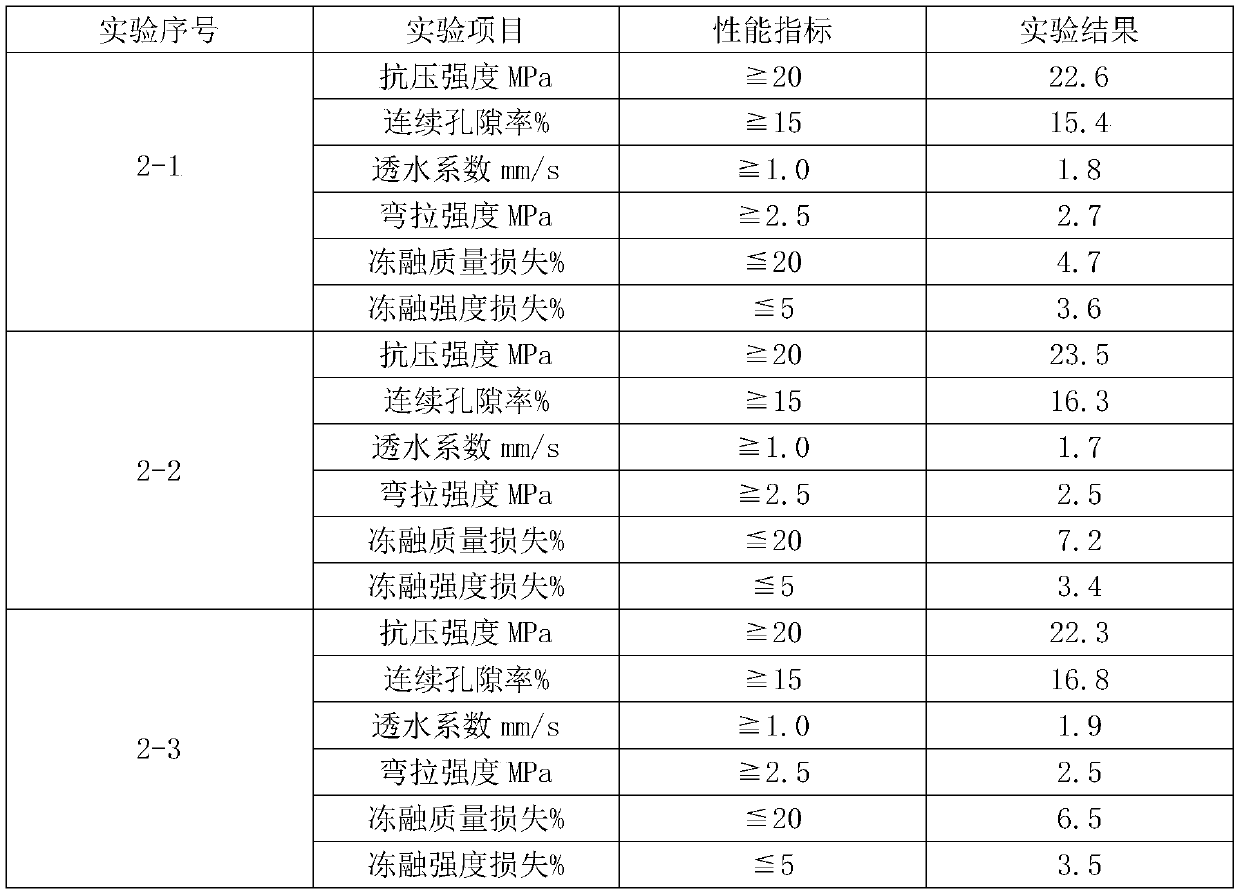

[0085] Embodiment 2: Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the raw materials prepared by the recycled aggregate permeable concrete containing red bricks in Embodiment 2 include the following components in parts by weight Composition: 350 parts of ordinary Portland cement, 575 parts of natural gravel, 575 parts of recycled aggregate containing red brick, 13 parts of permeable cement, 1.05 parts of water reducing agent, and 0.45 parts of polypropylene fiber.

Embodiment 3

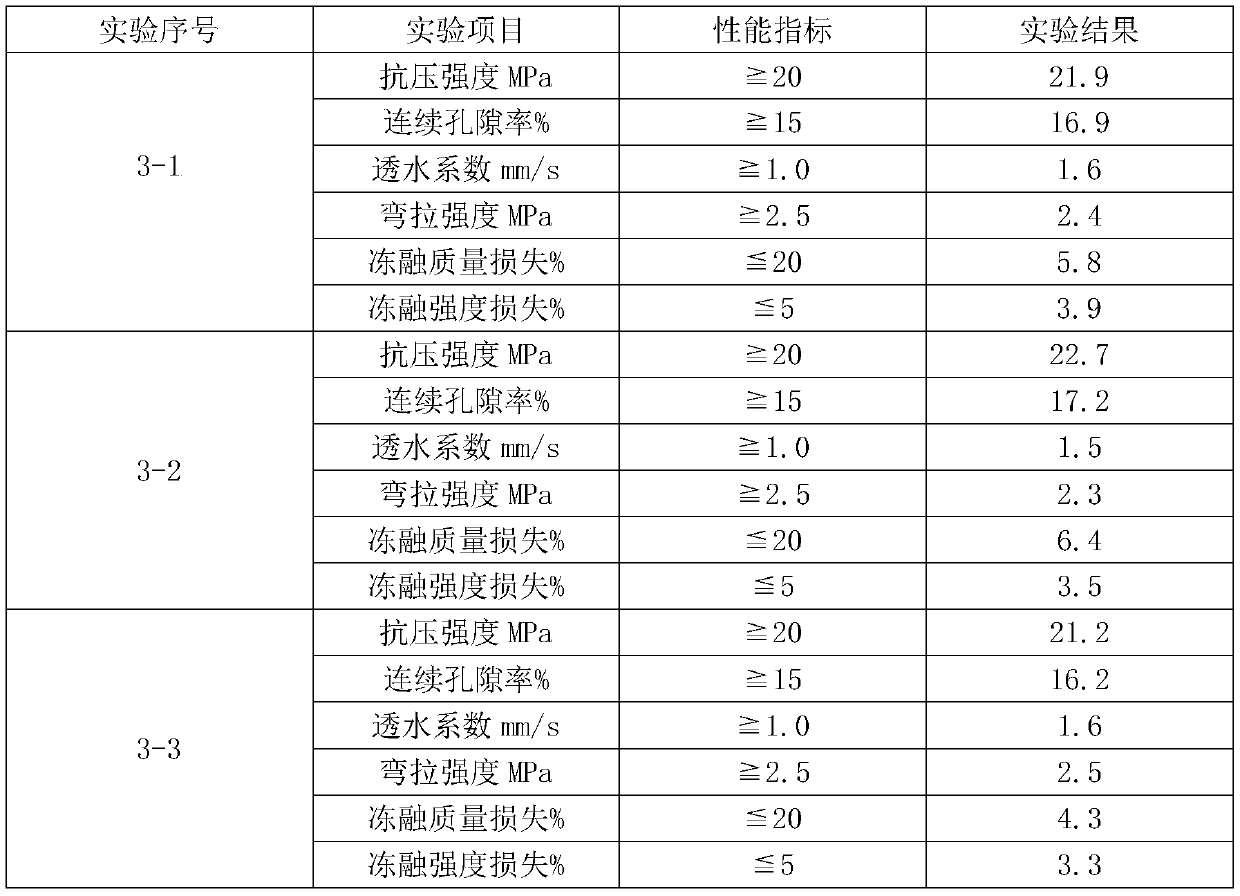

[0086] Embodiment 3: Embodiment 3 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the raw materials prepared from the recycled aggregate permeable concrete containing red bricks in Embodiment 3 include the following components in parts by weight Composition: 400 parts of ordinary Portland cement, 330 parts of natural crushed stone, 770 parts of recycled aggregate containing red brick, 14 parts of permeable cement, 1.2 parts of water reducing agent, and 0.45 parts of polypropylene fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com