A kind of gypsum-based 3D printing material and preparation method thereof

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problems of high production cost, environmental pollution, low molding strength, etc., and achieve the effect of maintenance-free, production cost reduction, and stable flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of gypsum-based 3D printing material, by weight, comprises the following components:

[0034] Hemihydrate gypsum (plaster of paris): 100 parts, protein retarder: 0.16 parts, calcium hydroxide: 0.05 parts, water-reducing polycarboxylate superplasticizer (KH-5 polymer produced by Wuhan Huaxuan High-tech Co., Ltd. Carboxylic acid superplasticizer mother liquor): 0.8 parts, hydroxypropyl methylcellulose: 1.6 parts, attapulgite: 1 part

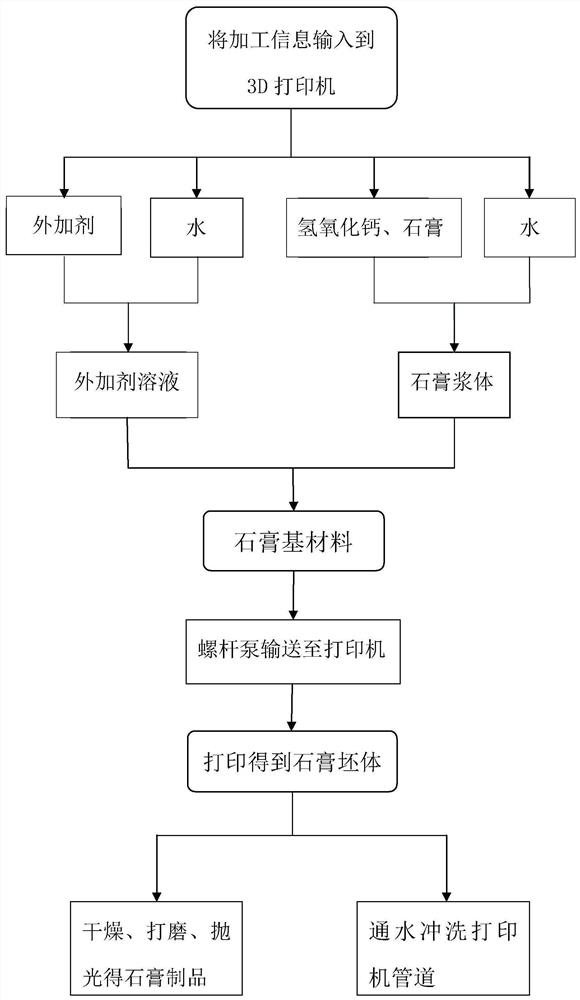

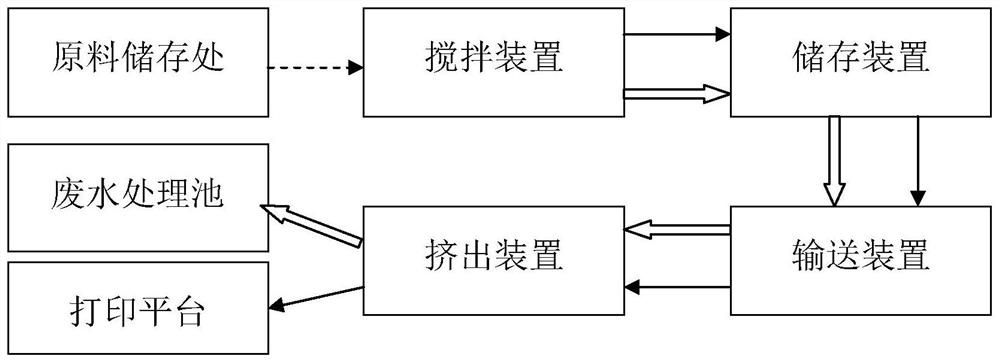

[0035] Such as figure 1 , figure 2 As shown, among them, figure 2 The dotted line in the middle is the flow route of the powder, the arrow in the solid line is the flow route of the slurry, and the blank arrow is the flow route of the slurry. The above-mentioned gypsum-based 3D printing material is specifically prepared by the following method:

[0036] 1) Design the 3D model information of the object to be printed in the computer, and convert the 3D model information into processing codes and then input it to the 3D printer;

...

Embodiment 2

[0043] A kind of gypsum-based 3D printing material, by weight, comprises the following components:

[0044] Hemihydrate gypsum (plaster of paris): 100 parts, protein retarder: 0.16 part, calcium hydroxide: 0.04 part, polycarboxylate superplasticizer powder (PCE-F10 polycarboxylate produced by Shanghai Chemical Building Materials Additive Co., Ltd. powder): 1 part, hydroxypropyl methylcellulose: 1.2 parts, hydrophilic fumed nano-silica: 1.6 parts

[0045] Such as figure 1 , figure 2 As shown, among them, figure 2 The dotted line in the middle is the flow route of the powder, the arrow in the solid line is the flow route of the slurry, and the blank arrow is the flow route of the slurry. The above-mentioned gypsum-based 3D printing material is specifically prepared by the following method:

[0046] 1) Design the 3D model information of the object to be printed in the computer, and convert the 3D model information into processing codes and then input it to the 3D printer;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com