A kind of method for preparing pentamethyldipropylene triamine

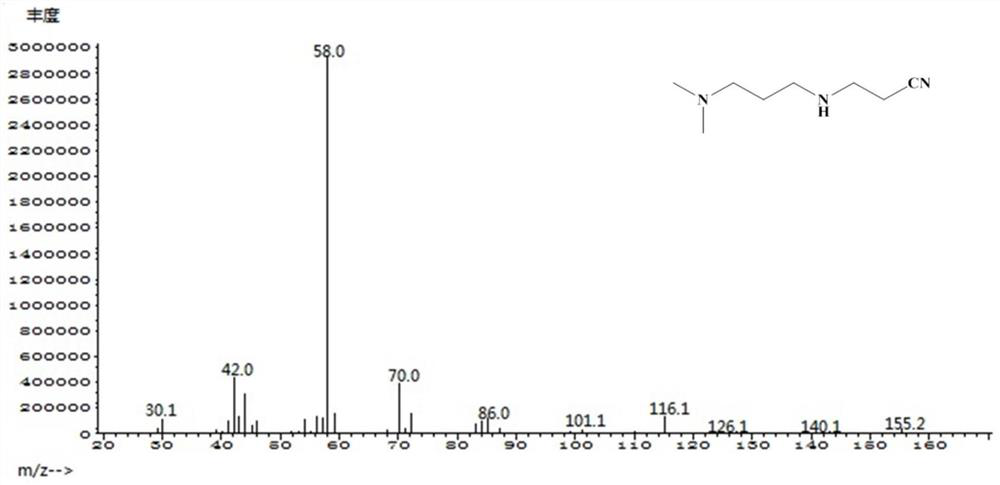

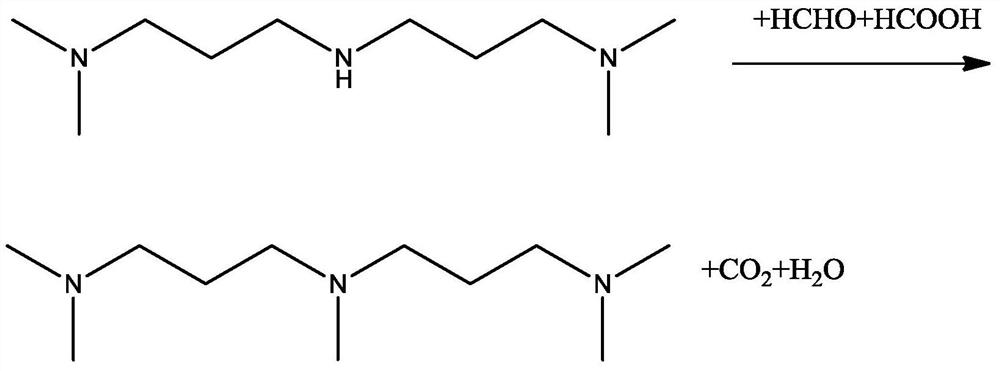

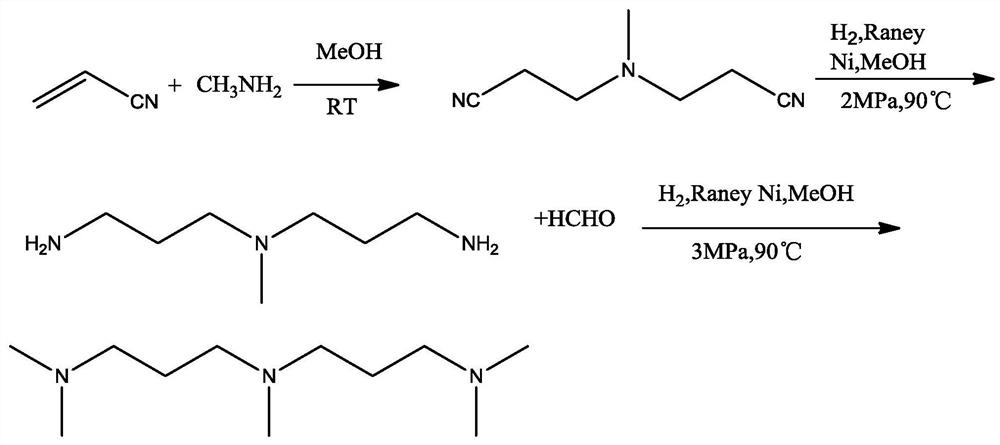

A technology of pentamethyldipropylenetriamine and dimethylaminopropylamine, which is applied to the preparation of amino compounds from amines, carboxylic acid nitriles, amino compounds, etc., and can solve the problem of many by-products, difficult hydrogenation, and raw material methylamine. Great odor and other problems, to achieve the effect of reducing the formation of by-products, reasonable acid distribution, and accelerated hydrogenation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of 1# modified carrier:

[0052] The spherical γ-Al 2 O 3 (Particle size 3mm, specific surface area 280m 2 / g) calcined at 450°C for 4h. Prepare ammonium fluorosilicate and niobium nitrate with 100ml deionized water containing 5g SiO 2 , 1g Nb 2 O 5 immersion solution, then heated to 90 °C to form a homogeneous solution, 94 g of γ-Al 2 O 3 Add it to the dipping solution, immerse it at 90°C for 12h, bake it in a 120°C oven for 12h; finally move it to a muffle furnace, heat it up to 500°C for 8 hours at 3°C / min in an air atmosphere, and obtain a mass Fraction is 5% SiO 2 +1%Nb 2 O 5 +94%γ-Al 2 O 3 modified carrier.

[0053] Preparation of 1# supported palladium-based catalyst precursor:

[0054] Prepare a nitrate impregnation solution containing 4g palladium, 1g zinc and 0.3g rhenium with 80ml deionized water, heat to 80°C to form a homogeneous solution, add 94.7g 1# modified carrier, impregnate it at 80°C for 8h, and then immerse it at 120°C for...

Embodiment 2

[0056] Preparation of 2# modified carrier:

[0057] The spherical γ-Al 2 O 3 (Particle size 3mm, specific surface area 280m 2 / g) calcined at 400°C for 8h. Prepare ammonium fluorosilicate and niobium nitrate with 120ml deionized water containing 10g SiO 2 , 0.5g Nb 2 O 5 dipping solution, then heated to 80 °C to form a homogeneous solution, 89.5 g of γ-Al 2 O 3 Add it to the dipping solution, soak it at 80°C for 16h, bake it in an oven at 110°C for 8h; finally move it to a muffle furnace, heat it up to 450°C for 8 hours at 2°C / min in an air atmosphere, and obtain a mass Fraction 10% SiO 2 +0.5%Nb 2 O 5 +89.5%γ-Al 2 O 3 modified carrier.

[0058] Preparation of 2# supported palladium-based catalyst precursor:

[0059] Prepare a nitrate impregnation solution containing 10g palladium, 0.5g zinc and 0.2g rhenium with 100ml deionized water, heat it to 90°C to form a homogeneous solution, add 89.3g 2# modified carrier, soak it at 90°C for 24h, and then Bake in an oven...

Embodiment 3

[0061] 3# Modified carrier preparation:

[0062] The spherical γ-Al 2 O 3 (Particle size 3mm, specific surface area 280m 2 / g) calcined at 500°C for 4h. Prepare ammonium fluorosilicate and niobium nitrate with 80ml deionized water containing 2g SiO 2 , 5g Nb 2 O 5 dipping solution, then heated to 85 °C to form a homogeneous solution, 93 g of γ-Al 2 O 3 Add it to the immersion solution, soak it at 85°C for 24h, bake it in an oven at 100°C for 12h; finally move it to a muffle furnace, heat it up to 300°C for 8 hours at 2°C / min in an air atmosphere, and obtain the mass fraction 2% SiO 2 +5%Nb 2 O 5 +93%γ-Al 2 O 3 modified carrier.

[0063] Preparation of 3# supported palladium-based catalyst precursor:

[0064] Prepare a nitrate impregnation solution containing 2g palladium, 0.8g molybdenum and 1g chromium with 50ml deionized water, heat to 90°C to form a homogeneous solution, then add 96.2g 3# modified carrier, impregnate it at 90°C for 8h, then at 110°C Bake in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com