PH-sensitive quaternary ammonium salt amphiphilic block copolymer and application thereof

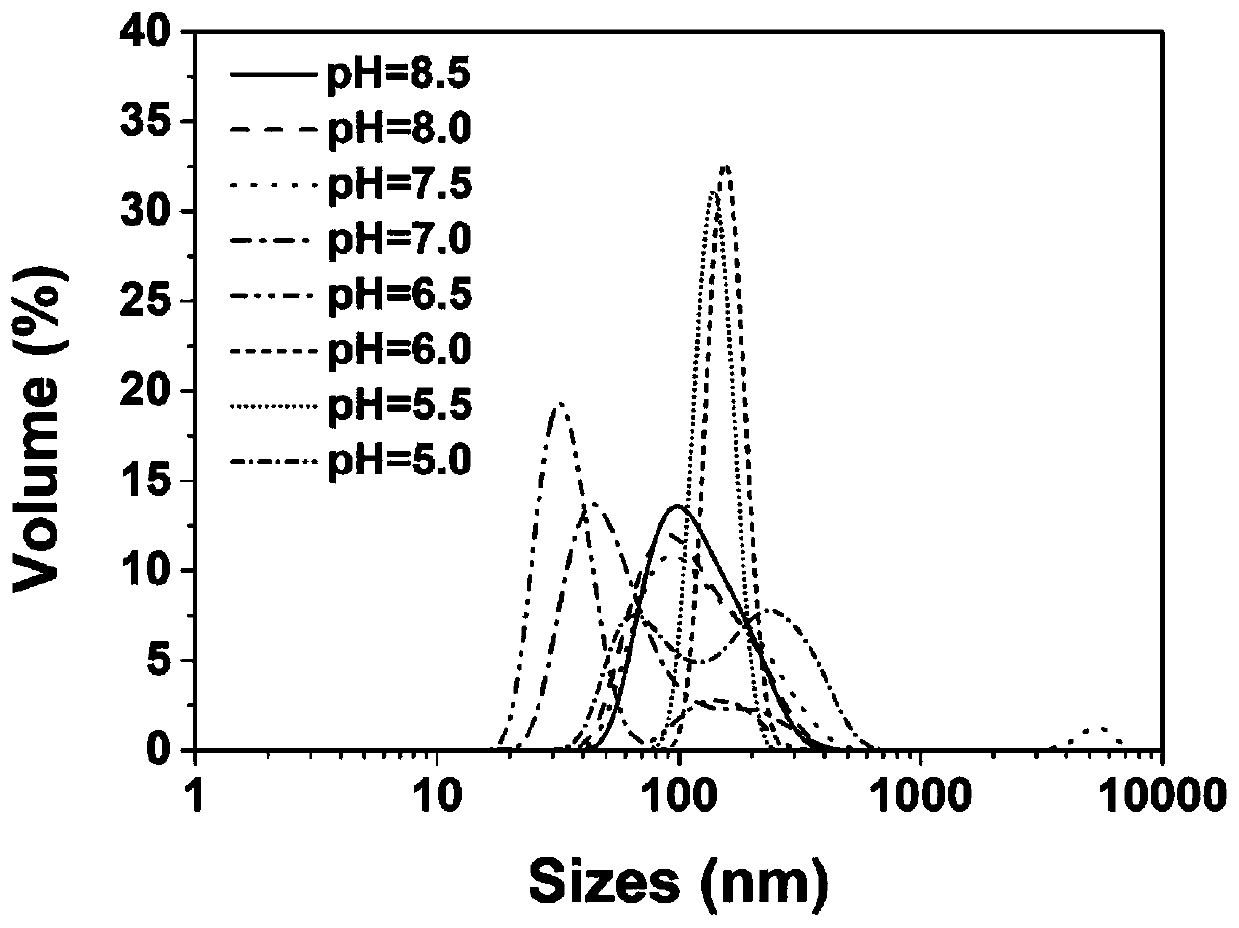

A technology of amphiphilic block and block copolymer, applied in the field of functional polymers and nano-gene delivery technology, amphiphilic pH-sensitive tri-block quaternary ammonium cationic copolymer, which can solve the problem of no proton buffering ability and other problems, to achieve the effect of high gene loading capacity and high transfection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

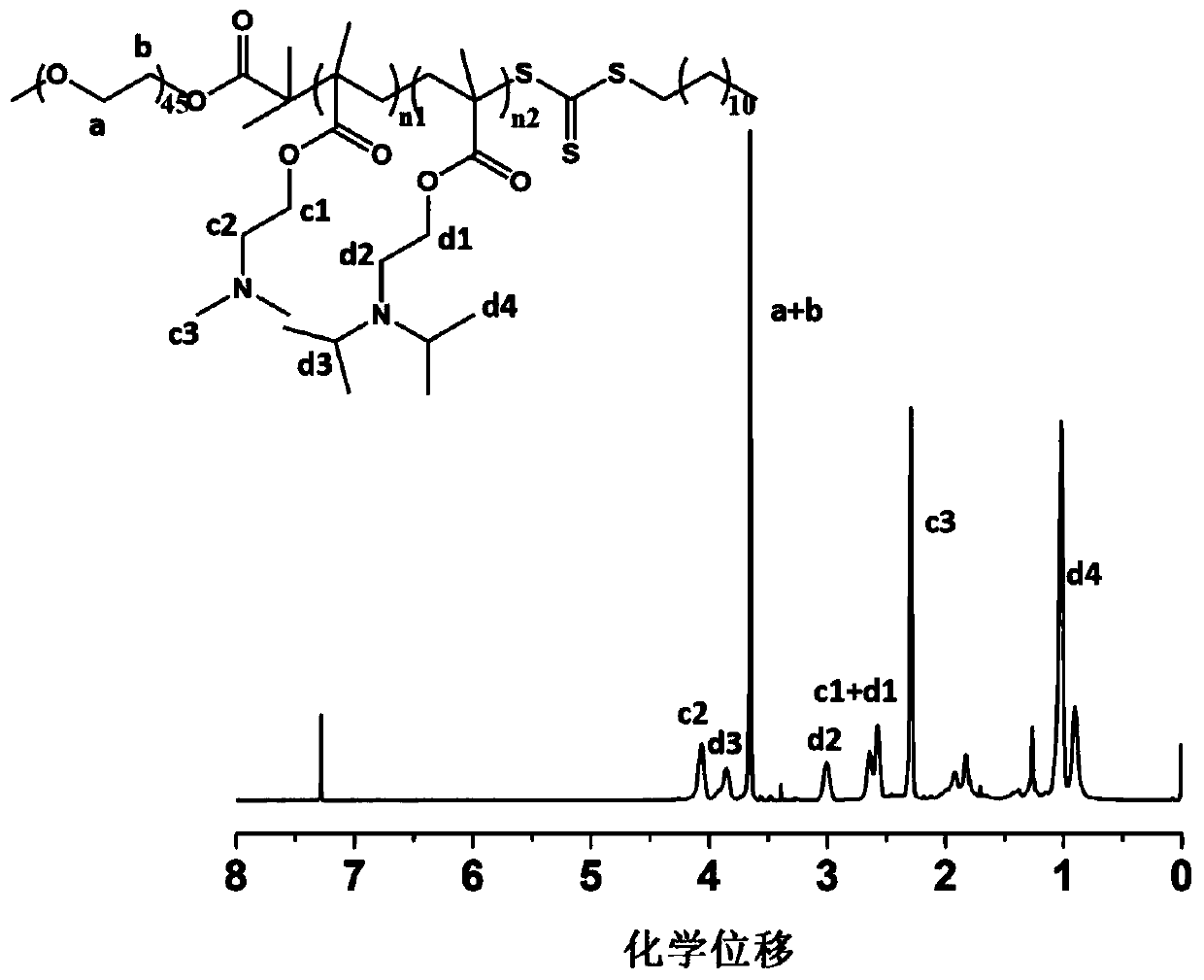

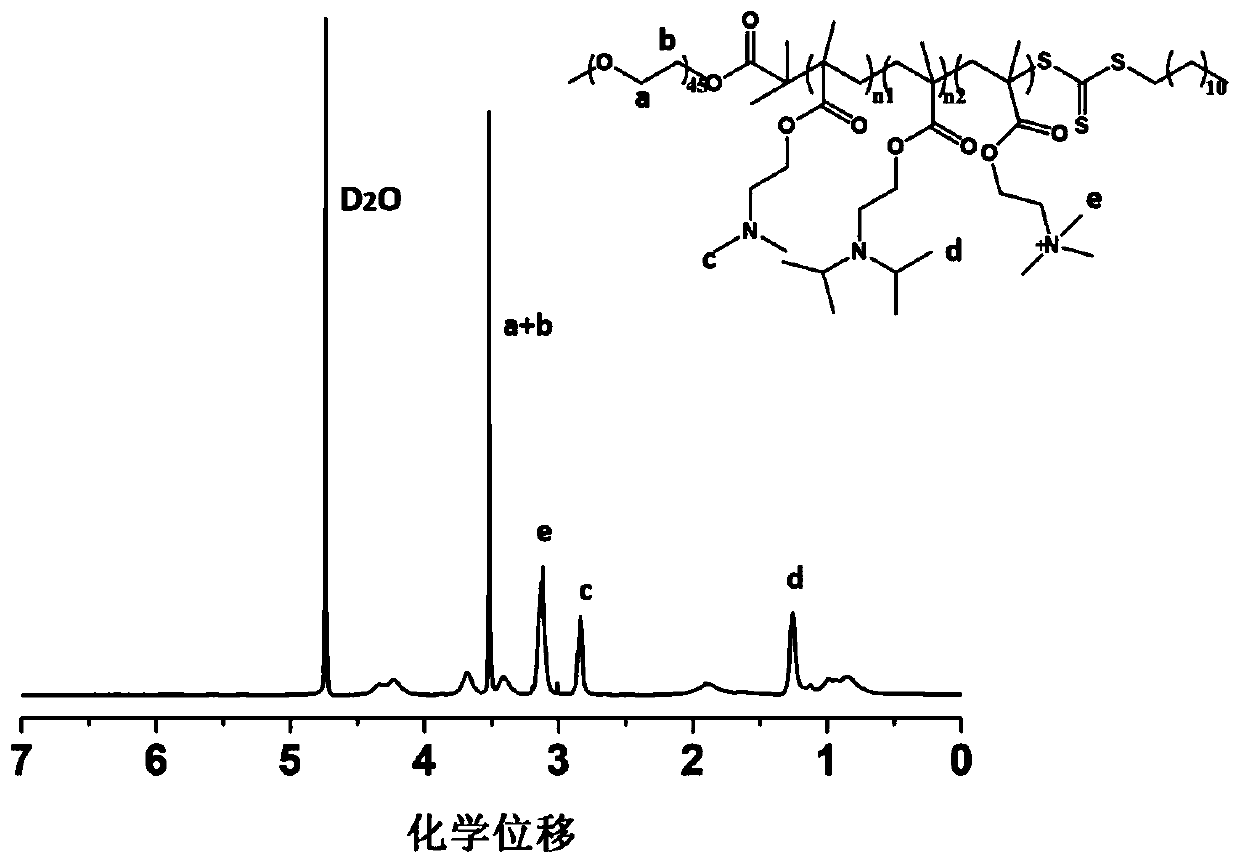

[0035] Take a 25ml schlink tube and add 0.4g (0.2mmol) PEG to the tube 2k -CTAm (Theranostics, 2017, 7, 3432-3445), 5ml dry dimethylformamide (DMF), then add 18.0mmol DMA and 2.0mmol DPA to the tube, add 6.56mg under argon protection after vacuuming (0.04mmol) AIBN, then continue to vacuumize and fill with argon, after circulating three times, place it in an oil bath at 70°C for 24h, and the product is determined by nuclear magnetic resonance in DDE (deuterium band chloroform), as figure 1 ). After the reaction is finished, add 3600mg (12mmol) TMA I, 5ml dry DMF to each tube, add 6.56mg (0.04mmol) AIBN under argon protection after vacuumizing, continue to vacuumize and fill with argon, after circulating three times, place The reaction was continued in a 70°C oil bath for 24h. After the reaction, dialyze with distilled water to remove DMF, freeze-dry, and obtain the final product as an A-C-T triblock copolymer, marked as TDDE (T represents T segment, DD represents DPA / DMA cop...

Embodiment 2

[0037] Take a 25ml schlink tube, add 0.4g (0.2mmol) PEG2k-CTAm (Theranostics, 2017, 7, 3432-3445) and 5ml dry DMF to the tube, then add 16.0mmol DMA and 4.5mmol DPA to the tube, After vacuuming, add 6.56mg (0.04mmol) AIBN under the protection of argon, then continue to vacuumize and fill with argon, after three cycles, put it in an oil bath at 70°C for 24h. After the reaction is over, add 12.0mmolTMA·I and 5ml dry DMF to each tube, add 6.56mg (0.04mmol) AIBN under the protection of argon after vacuuming, continue to vacuumize and fill with argon, after three cycles, place at 70°C The reaction was continued in the oil bath for 24h. After the reaction, dialyze with distilled water to remove DMF, and freeze-dry to obtain A-C-T type block copolymer TDDE-2. The NMR characterization is shown in Table 1.

Embodiment 3-15

[0039] Press the synthetic method of embodiment 2, change the molecular weight of PEG or use RGD-PEG-CTAm, change the charging capacity of DPA, DMA, TMA I, prepare the series pH sensitive three-block quaternary ammonium salt cationic copolymers of different compositions, as Table 1 and figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com