Production process of polyurethane coating

A polyurethane coating and production process technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low production efficiency, easy skinning of materials, poor material dispersion, etc., to improve production efficiency, easy to mix and disperse, phase Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

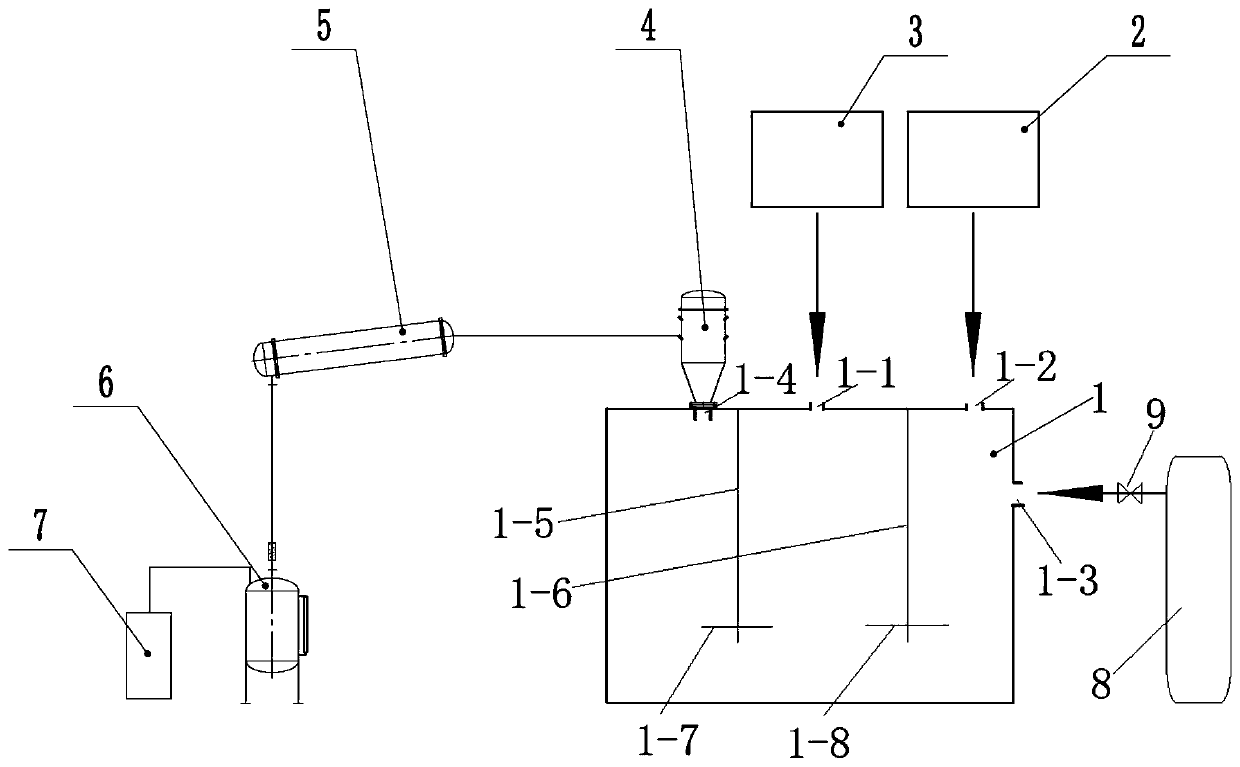

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 of the present application provides a kind of polyurethane coating, and concrete production step comprises:

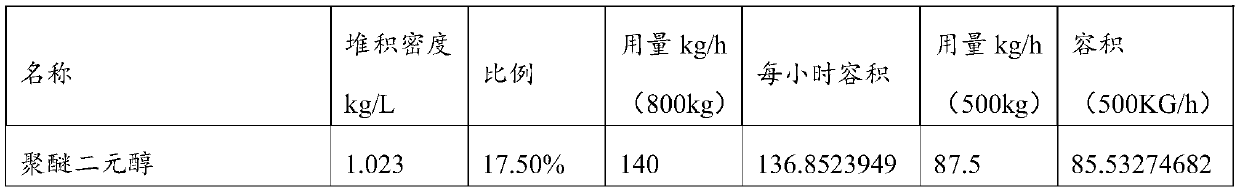

[0057] Step 1, according to the addition and parameter of table 1 material, fumed silica, nano-calcium carbonate, heavy superfine calcium carbonate and plasticizer (plasticizer comprises diisononyl phthalate and vegetable oil) Dehydrating and mixing in the first material dehydration kettle to obtain the first material, the water content of the first material is 0.05%;

[0058] Polyether polyols (polyether polyols include polyether diols and polyether triols) and isocyanate are mixed and polymerized in a polymerization tank to obtain the second material, wherein the polyether polyols are dehydrated in a polyether polyol dehydration tank in advance Carry out dehydration in middle, make the water content of polyether polyol be 0.05%;

[0059] Step 2, mixing the first material and the second material in the first mixing device to obtain the third mater...

Embodiment 2

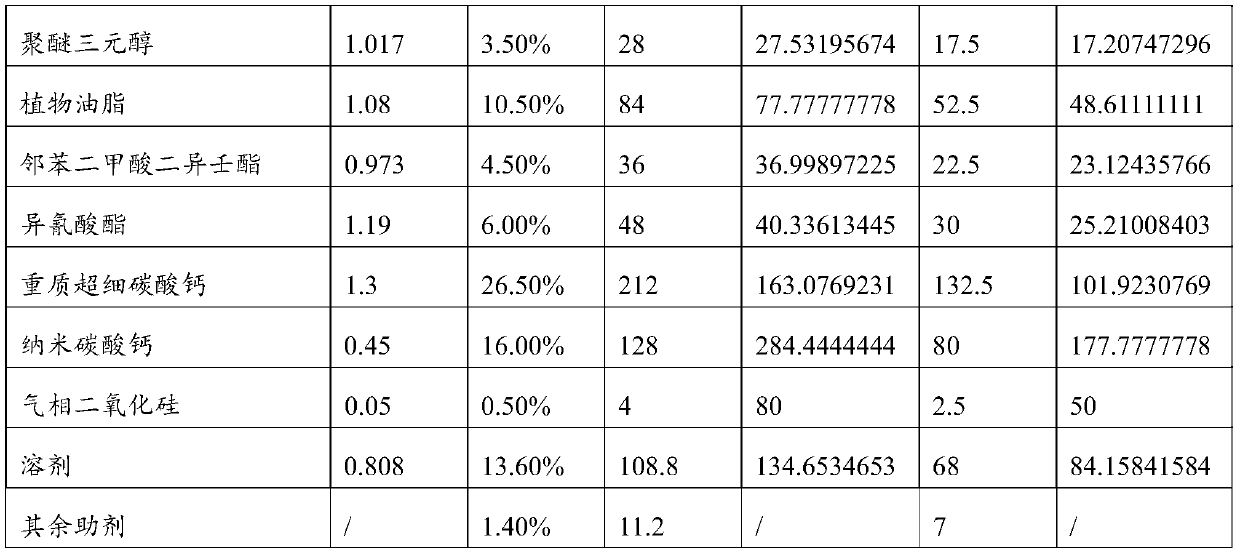

[0072] In Example 2 of the present application, the skinning, particle size and shelf life of the polyurethane coating products in Example 1 and Comparative Example 1 were tested, and the test results are shown in Table 3.

[0073] table 3

[0074] Test items Example 1 Comparative example 1 Crust condition no crust produce crust Product particle size ≤10μm ≤20μm shelf life 18 months 12 months

[0075] The above table shows that, due to the high water content of the material in Comparative Example 1, it is easy to form skins, and the dry skins cannot be broken up by physical methods. Due to the skinning, the dispersion effect is seriously affected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com