Light-weight low-conductivity ablation shape maintaining heat-resistant coating and preparation and application thereof

A heat-resistant coating and lightweight technology, applied in the direction of epoxy resin coatings, coatings, and devices for coating liquid on the surface, can solve the problem of difficult to achieve surface structure dimensions of aerospace products, changes in the structure and shape of aerospace products, and impact Aerospace products work performance and other issues, to achieve the effect of solving the problem of high-temperature aerodynamic scour heat protection, improving process performance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

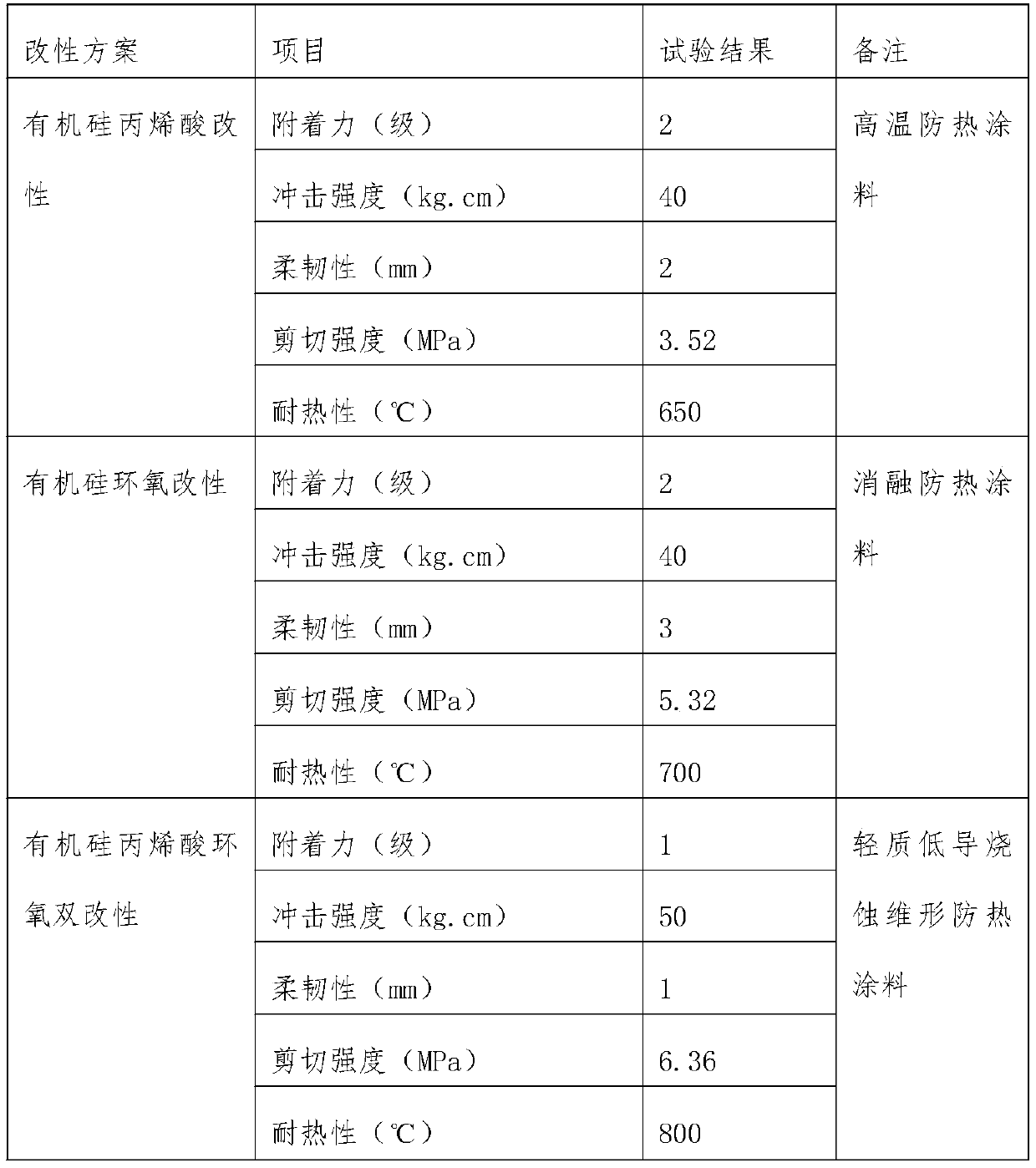

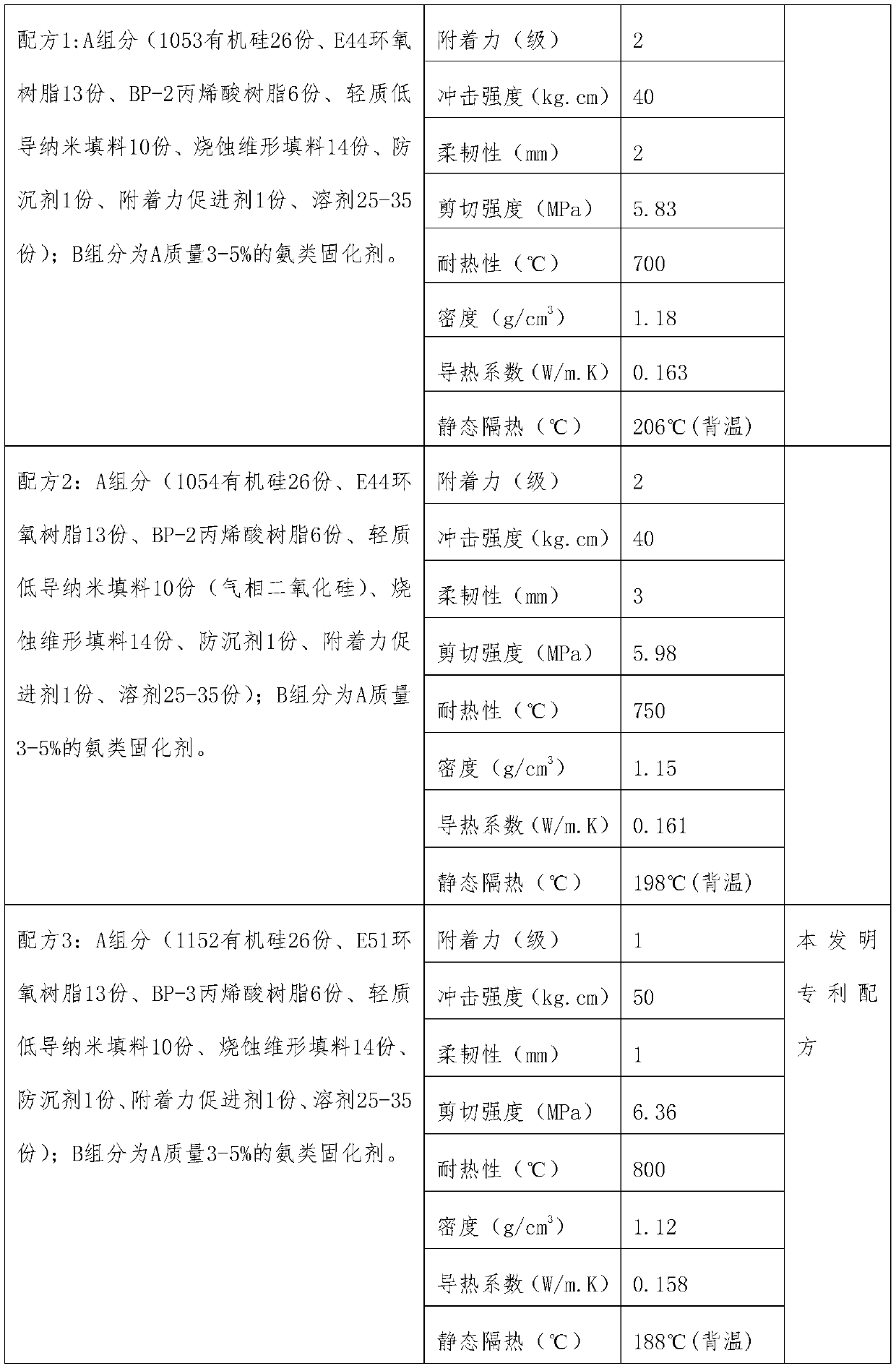

[0034] Embodiment 1: coating formula sees table 3

[0035] Table 3 Heat-resistant coating formula

[0036]

[0037] The preparation method of described heat-resistant paint specifically comprises the following processes:

[0038] (1) Premixing: Weigh 1152 organic silicon resin, E51 epoxy resin, BP-3 acrylic resin, nano fumed silica, hollow glass microspheres, additives and 80% solvent by weight and add to the dispersed sand Mill, stir and mix evenly with a nylon rod;

[0039] (2) Dispersion: Disperse the pre-mixed heat-resistant coating at a speed of 600-800r / min for 50min-60min, and then disperse at a speed of 1000-1600r / min for 100min-120min; Over 35°C, to ensure that the coating system is evenly mixed;

[0040] (3) Grinding: Install the grinding medium (glass beads or zirconia beads of φ1.5~φ3) in the horizontal sand mill, set the temperature and pressure, and carry out the two coatings dispersed in step (2). Circular sanding; during sanding, the temperature of the m...

Embodiment 2

[0044] Get the prepared coating of embodiment 1 and carry out performance test, and test process specifically comprises the following steps:

[0045] (a) Pretreatment of the test piece: the test piece (aluminum test piece anodized, magnesium test piece oxidized) was cleaned with ethyl acetate or acetone.

[0046] (b) Coating preparation: Weigh 1000g of component A of the heat-resistant coating, then weigh 30g to 50g of component B, mix components A and B evenly, and add solvent to adjust to a viscosity that is easy to spray;

[0047](c) Spraying: choose a small spray gun for spraying, the air pressure is controlled at about 0.3MPa, the distance of the spray gun is about 20cm-30cm, and the thickness of the single-layer wet film is 30μm-50μm; the thickness of the conventional performance and heat-resistant coating is controlled at 30μm-50μm, The thickness of the thermal insulation coating is controlled at 0.8mm~1.0mm, and the thickness of the thermal performance test coating is ...

Embodiment 3

[0053] The light-weight low-conductivity ablation-dimensional heat-resistant coating prepared in Example 1 is used for the thermal protection of the cabin structure of aerospace products, specifically comprising the following steps:

[0054] (a) Pretreatment of the cabin body: cleaning the outer surface of the cabin with ethyl acetate or acetone to oxidize the magnesium alloy on the outer surface of the cabin;

[0055] (b) Process protection spraying: Spray light-weight low-conductivity ablation-dimensional heat-resistant paint within 24 hours after the cabin is oxidized as process protection;

[0056] (c) Spraying: Weigh component A of the heat-resistant coating: component B = 100: 5 to 7, mix components A and B evenly, add solvent to adjust to a viscosity that is easy to spray; then select a large spray gun to spray, air pressure Control at about 0.35MPa, spray gun distance about 30cm, single-layer wet film thickness between 30μm and 50μm, and coating thickness between 0.8mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com