Method for producing bacillus polymyxa additive through Baijiu distillers' grains and application of bacillus polymyxa additive

A technology for Bacillus polymyxa and liquor lees is applied in the directions of microorganism-based methods, biochemical equipment and methods, applications, etc., and can solve the problems that the nutritional value of fermented products is not significantly improved, the fermentation process is cumbersome, and the input cost is high. Improve the content of crops, change the micro-ecological environment, and improve the effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

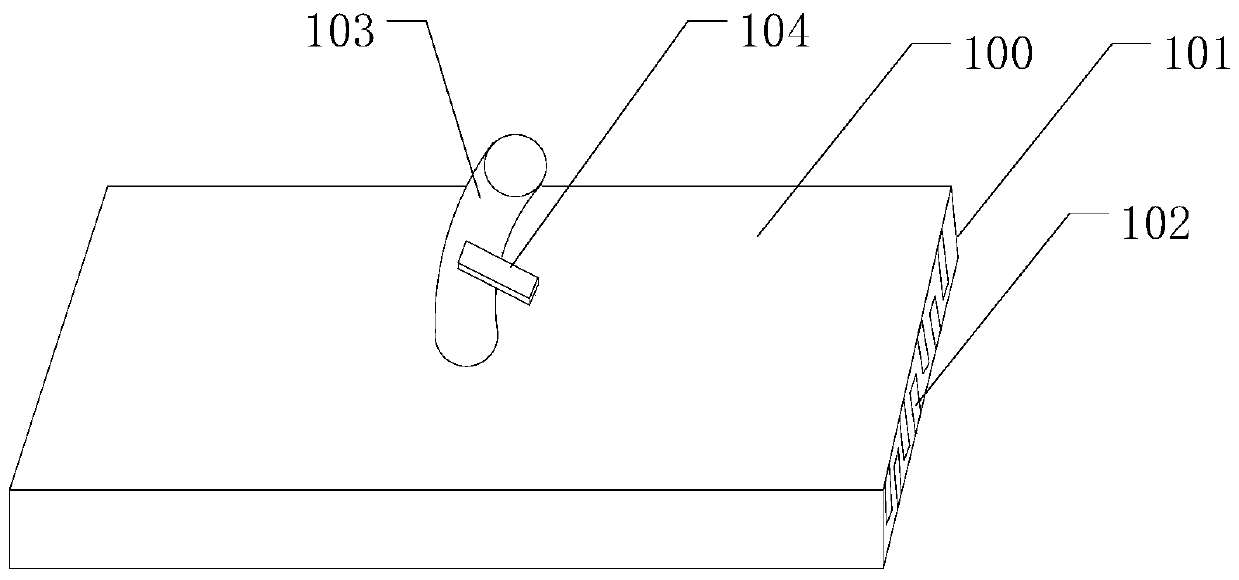

Image

Examples

Embodiment 1

[0065] A method for producing bacillus polymyxa additive by utilizing distiller's grains of distiller's liquor, comprises the following steps:

[0066] (1) Put the fresh distiller's grains in the blender, set the initial temperature to 100°C, and the stirring speed to 500rpm. After keeping it for 30 minutes, reduce the stirring speed to 200rpm, and use a gradient cooling method (cooling once every 20min, followed by 5°C, 10°C, 15°C...), cooling from 100°C to 45°C within two hours, keeping warm at 45°C until the water content of the distiller's grains is 20%, and then removing the rice husks in the distiller's grains to obtain pretreated distiller's grains;

[0067] (2) Add 10% puffed corn flour in mass ratio to the obtained pretreated distiller's grains, after mixing evenly, add the Bacillus polymyxa fermentation broth with a mass ratio of 1% according to the total amount of pretreated distiller's grains, and mix to form a fermented The base material is then piled up into a sq...

Embodiment 2

[0071] A method for producing bacillus polymyxa additive by utilizing distiller's grains of distiller's liquor, comprises the following steps:

[0072] (1) (1) with embodiment 1;

[0073] (2) Add 10% puffed corn flour in mass ratio to the obtained pretreated distiller's grains, after mixing evenly, add 3% of the Bacillus polymyxa fermentation broth with a mass ratio of 3% according to the total amount of pretreated distiller's grains, and mix to form a fermented The base material is then piled up into a square structure of 15cm. It is fermented aerobically at 37°C and the humidity is controlled at 50%. When the temperature rises to 40°C, the material is turned over once, and when the temperature rises to 50°C, the material is turned over every 3 hours for co-fermentation 72h, obtain the fermentation product; wherein, keep the water content of the fermentation material at 50% during the fermentation process;

[0074] (3) is the same as (3) of embodiment 1.

[0075]Measure the...

Embodiment 3

[0077] (1) (1) with embodiment 1;

[0078] (2) Adding 15% puffed corn flour in mass ratio to the obtained pretreated distiller's grains, after mixing evenly, adding 5% of the Bacillus polymyxa fermentation broth with a mass ratio of 5% according to the total amount of pretreated distiller's grains, and mixing to form a fermented The base material is then piled up into a square structure of 20cm. It is fermented aerobically at 37°C and the humidity is controlled at 45%. When the temperature rises to 40°C, the material is turned once, and when the temperature rises to 50°C, the material is turned every 3 hours for co-fermentation 96h, obtain the fermentation product; wherein, keep the water content of the fermentation material at 50% during the fermentation process;

[0079] (3) is the same as (3) of embodiment 1.

[0080] Measure the bacterium content with PCA counting method, the bacillus mutans additive bacterium content of the preparation of above-mentioned embodiment is 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com