A kind of Si-free rare earth magnesium alloy nodulizer and its preparation method and application

A technology of nodularizing agent and rare earth magnesium, which is applied in the field of nodular cast iron, can solve the problems of poor anti-decay ability of ordinary nodulizers and high raw material requirements, and achieve strong anti-spheroidizing anti-decay ability, reduce Si content, and improve anti-decay ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

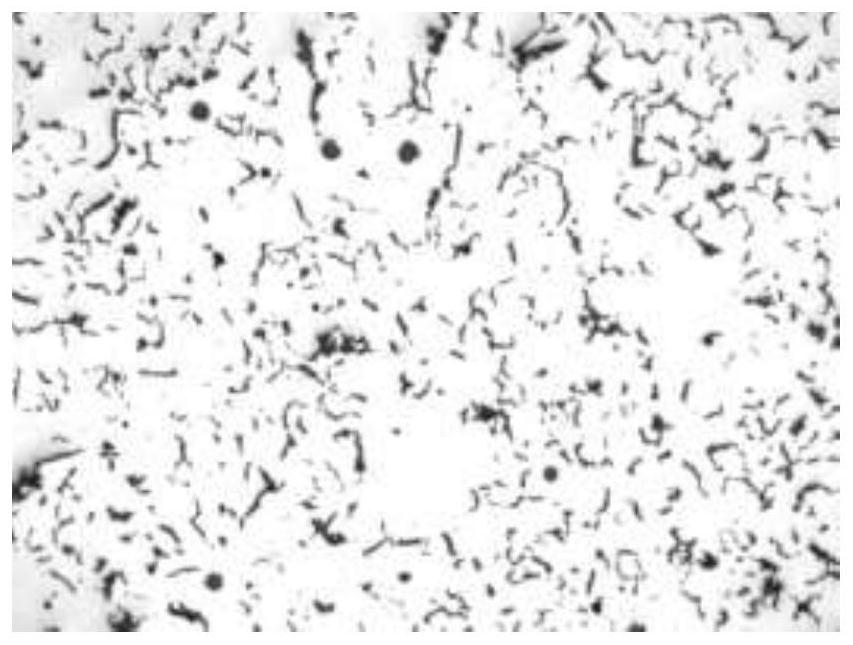

Embodiment 1

[0043] This embodiment provides a rare earth magnesium alloy nodulizer without Si and its preparation method: the mass percent of each constituent element in the rare earth magnesium alloy nodulizer without Si is: Al 1%, RE 8%, Ca 3%, Sb 1%, Bi 1%, the balance is Mg, wherein: RE is Ce.

[0044] The preparation method of this nodulizer is carried out according to the following steps:

[0045] 1) Using pure magnesium, pure aluminum, Mg-RE master alloy and Mg-Ca master alloy as raw materials, prepare materials according to the mass percentage requirements of the above-mentioned constituent elements, and dry each block raw material at 200°C for at least 3 hours;

[0046] 2) Preheat the melting crucible (made of low carbon steel) to 500°C, then add pure aluminum and pure magnesium and raise the temperature to 720°C until the pure aluminum and pure magnesium melt;

[0047] 3) Then add Mg-RE master alloy and Mg-Ca master alloy and raise the temperature to 750°C, keep warm for 15min,...

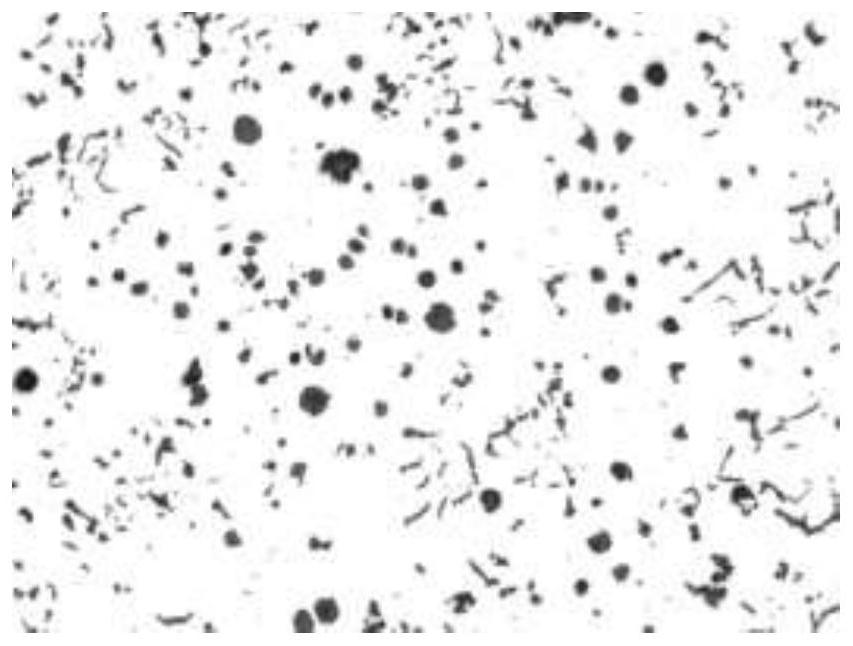

Embodiment 2

[0051] This embodiment provides a kind of Si-free rare earth magnesium alloy spheroidizer and its preparation method: the mass percent of each constituent element in the Si-free rare earth magnesium alloy spheroidizer is: Al 3%, RE 10%, Ca 5%, Sb 3%, Bi 3%, the balance is Mg, wherein: RE is Ce.

[0052] The preparation method of this nodulizer is carried out according to the following steps:

[0053] 1) Using pure magnesium, pure aluminum, Mg-RE master alloy and Mg-Ca master alloy as raw materials, prepare materials according to the mass percentage requirements of the above-mentioned constituent elements, and dry each block raw material at 200°C for at least 3 hours;

[0054] 2) Preheat the melting crucible (made of low-carbon steel) to 500°C, then add pure aluminum and pure magnesium and raise the temperature to 730°C until the pure aluminum and pure magnesium melt;

[0055] 3) Then add Mg-RE master alloy and Mg-Ca master alloy and heat up to 760°C, keep warm for 20min, then...

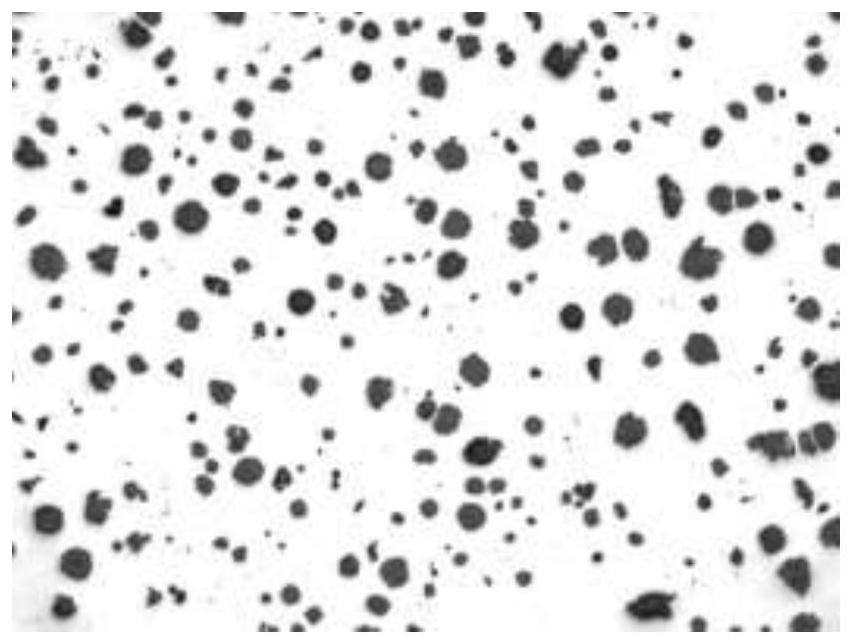

Embodiment 3

[0059] This embodiment provides a rare earth magnesium alloy nodulizer without Si and its preparation method: the mass percent of each constituent element in the rare earth magnesium alloy nodulizer without Si is: Al 3%, RE 9%, Ca 3%, Sb 2%, Bi 1%, the balance is Mg, wherein: RE is Ce.

[0060] The preparation method of this nodulizer is carried out according to the following steps:

[0061] 1) Using pure magnesium, pure aluminum, Mg-RE master alloy and Mg-Ca master alloy as raw materials, prepare materials according to the mass percentage requirements of the above-mentioned constituent elements, and dry each block raw material at 200°C for at least 3 hours;

[0062] 2) Preheat the melting crucible (made of low carbon steel) to 500°C, then add pure aluminum and pure magnesium and raise the temperature to 725°C until the pure aluminum and pure magnesium melt;

[0063] 3) Then add Mg-RE master alloy and Mg-Ca master alloy and heat up to 755°C, keep warm for 18min, then stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com