Thick plate for high-strength container with excellent core toughness and manufacturing method thereof

A high-strength, core technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

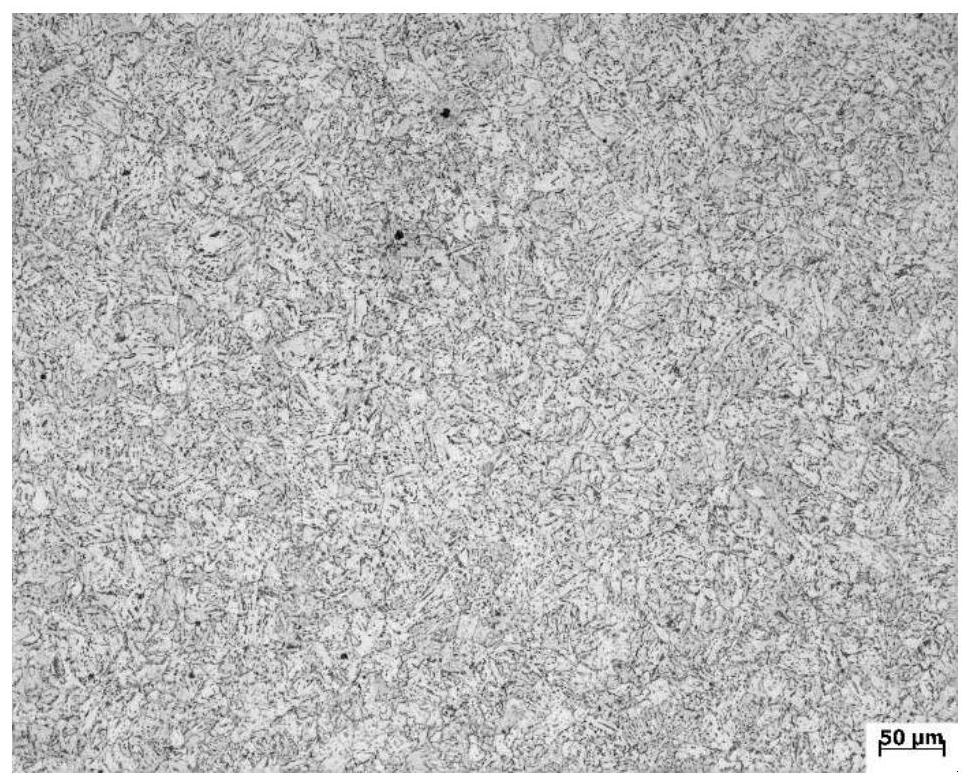

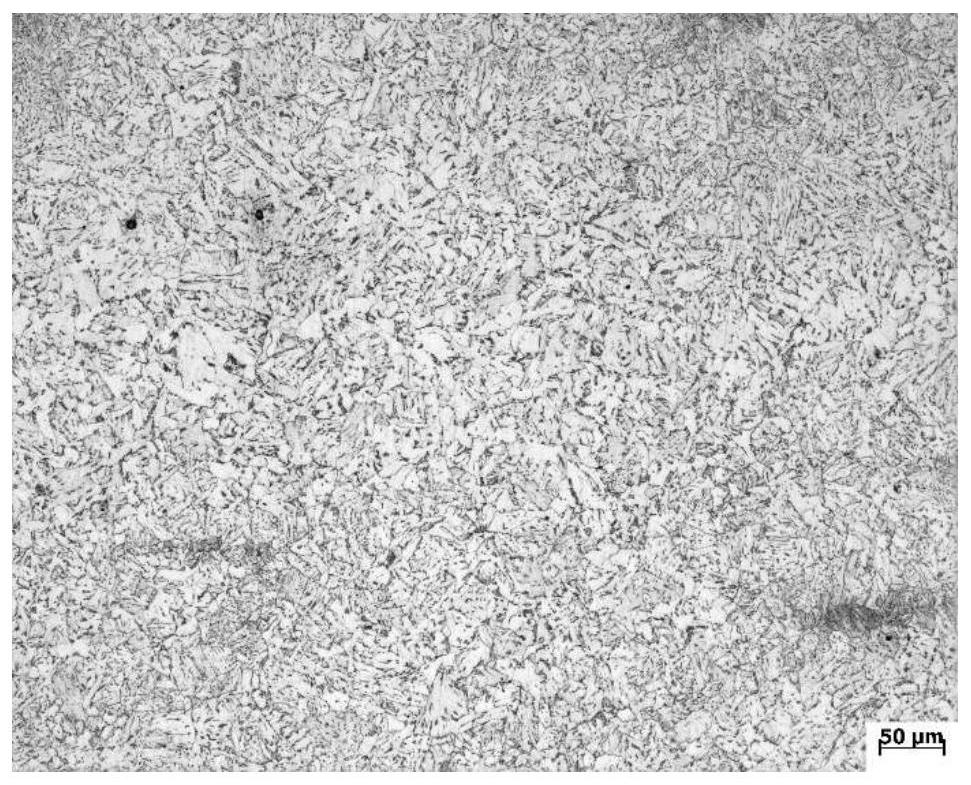

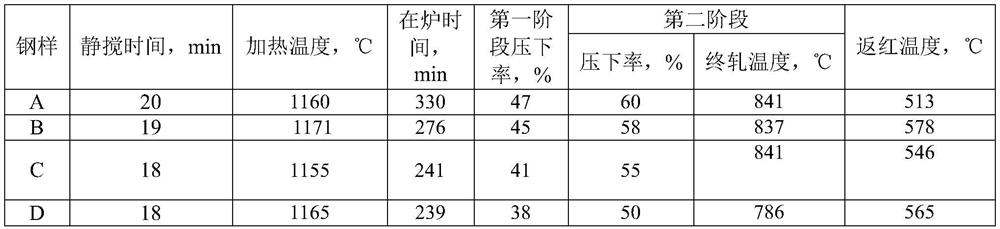

[0032] The following examples provide a thick plate for high-strength containers with excellent core toughness and its manufacturing method. The chemical composition is shown in Table 1, the smelting and rolling process parameters are shown in Table 2, and the heat treatment process parameters are shown in Table 3. The specific steps are as follows: steelmaking and continuous casting: pretreatment of molten iron, S content in molten iron < 0.002wt%, converter steelmaking, deep deoxidation and desulfurization in LF furnace, adjustment of alloy composition to the target range, degassing in RH furnace, vacuum The temperature is less than or equal to 0.3 torr; the continuous casting is carried out with the weak cooling of the secondary cooling water and the low casting speed scheme, the casting speed is 0.8-1.2m / min, the thickness of the continuous casting slab is 260mm, and the casting slab is subjected to stack cooling treatment, and the stack cooling time is ≥48 hours;

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com