Niobium-containing high-carbon nickel-iron-based alloy and preparation method thereof

A nickel-iron-based alloy technology, applied in the field of nickel-iron-based alloys, to achieve low oxidation rate, high anti-oxidation film peeling ability, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0030] According to the chemical composition range of a niobium-containing high-carbon nickel-iron-based alloy of the present invention, the embodiment alloy was smelted in a vacuum induction furnace. The specific ingredients are shown in Table 1. Table 1 is the chemical composition of the alloy of Examples 1-3, the alloy of Comparative Example 1, the alloy of Comparative Example 2 and the commercial Ni alloy (the chemical composition is in mass fraction); wherein all alloys are cast.

[0031] After the alloy was smelted, it was poured into an ingot and heat treated. The heat treatment system was: 1180°C×1h / air cooling.

[0032] The chemical composition of table 1 embodiment alloy, comparative example alloy, commercial Ni alloy

[0033]

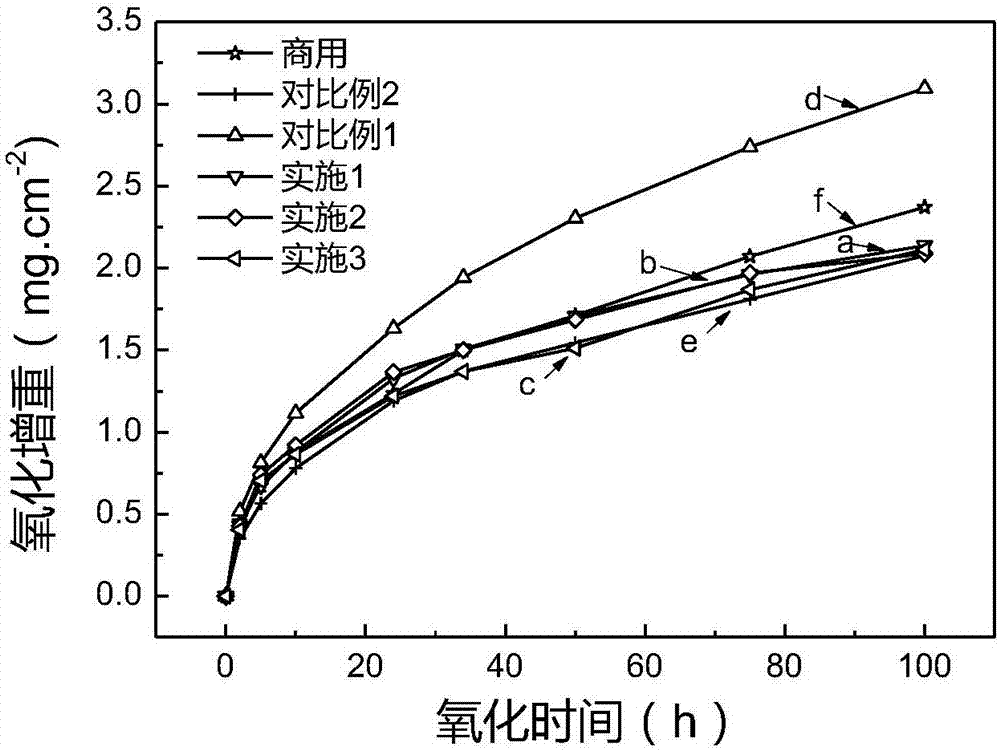

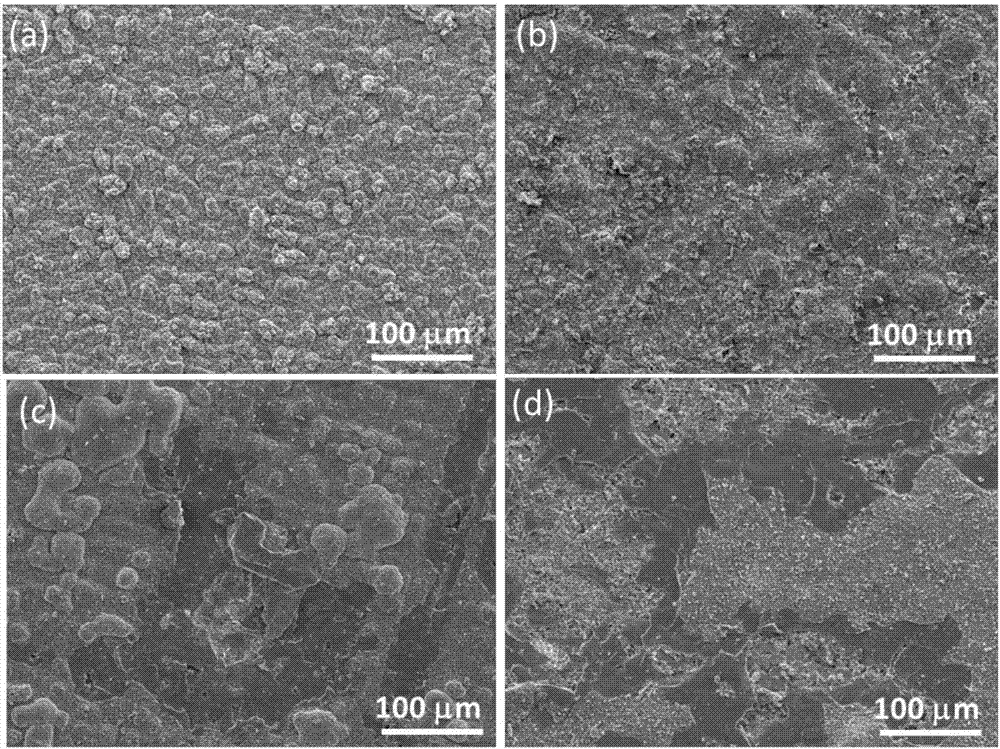

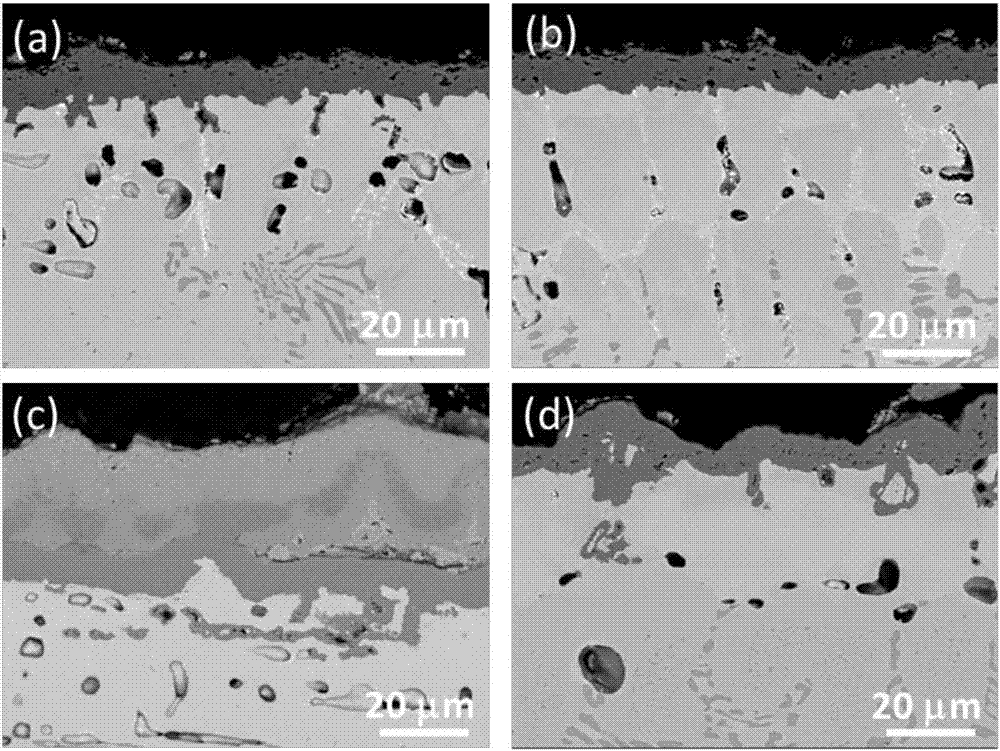

[0034] The mass changes of the alloys of Examples 1-3, Comparative Examples 1-2, and commercial Ni alloys were measured w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com